MAY

2023

Construction

DIVISION OF CONSTRUCTION

Quality Assurance

Program Manual

State of California

Department Of Transportation

CALIFORNIA

DEPARTMENT OF TRANSPORTATION

Construction Quality

Assurance Program Manual

Issued by

Division of Construction

GAVIN NEWSOM

Governor

TONY TAVARES

Director, Department of Transportation

MICHAEL KEEVER

Chief Deputy Director

DONNA BERRY

Chief Engineer

RAYMOND TRITT

Assistant Chief, Division of Construction

RAMON HOPKINS

Chief, Division of Construction

JOSEPH DONGO

Chief, Office of Construction Standards

© Copyright 2023 California Department of Transportation

All Rights Reserved. (No part of this manual may be reproduced in any form or by any electronic or mechanical

means including information storage and retrieval systems without the permission in writing from the California

Department of Transportation).

https://dot.ca.gov/manuals

State of California California State Transportation Agency

DEPARTMENT OF TRANSPORTATION

“Provide a safe and reliable transportation network

that serves all people and respects the environment”

Construction Quality Assurance Program

(CQAP) Manual

Issued by

Division of Construction

This manual provides quality assurance guidance on testing and inspection

to verify the quality of materials used in highway construction on Federal-

Aid Projects.

Approved By:

___________________________ _______________

Raymond Tritt Date

Assistant Chief

Division of Construction

California Department of Transportation

___________________________ _______________

Christopher S. Long Date

Infrastructure Team Leader

Federal Highway Administration

7/3/2023

7/3/2023

CONSTRUCTION QUALITY ASSURANCE PROGRAM MANUAL

Contents

California Department of Transportation • Division of Construction

May 2023 Page i

CONTENTS

Introduction ......................................................................................................................................... 1

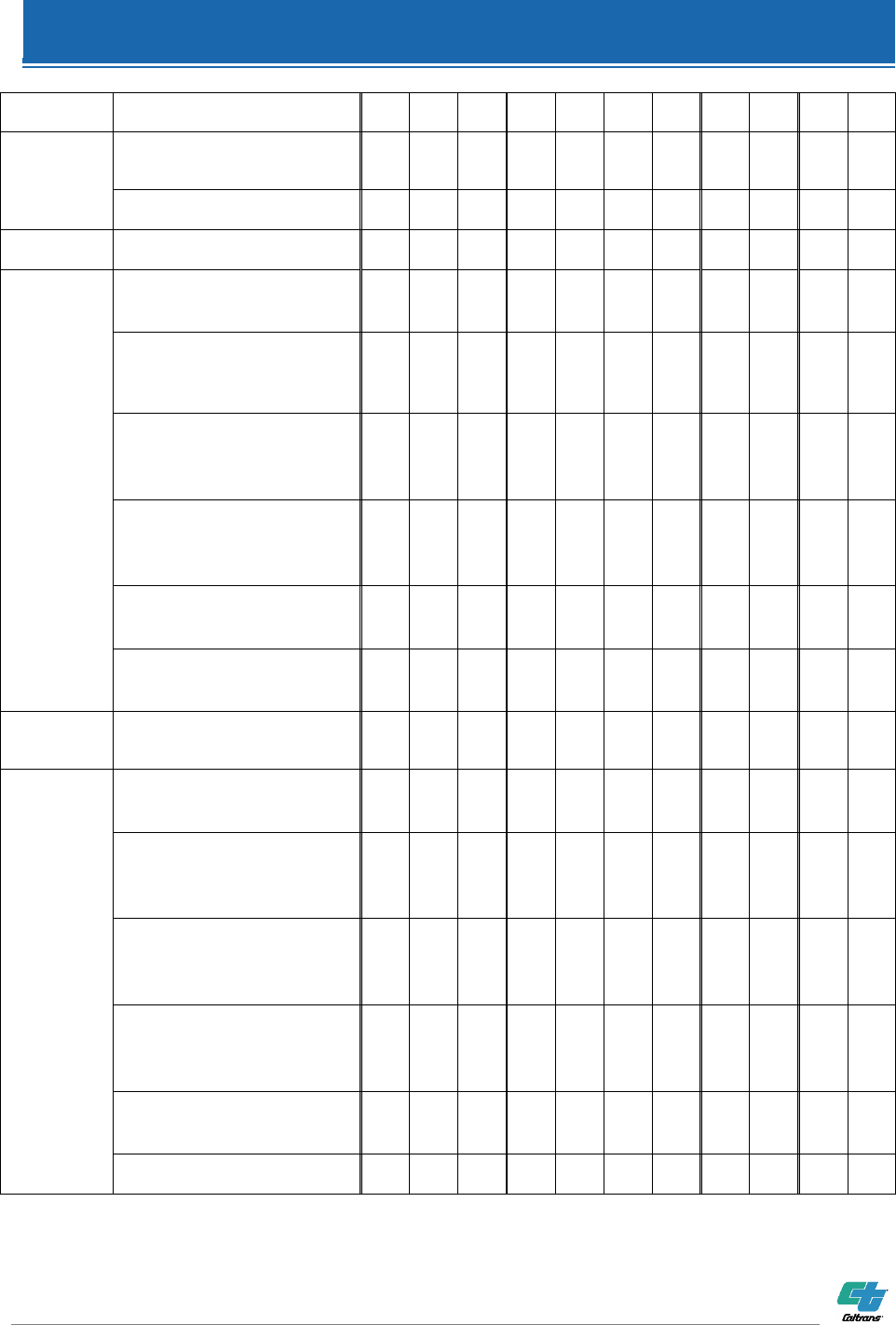

Figure 1. FHWA Six Core Elements of Quality Assurance Program....................................... 1

Construction Quality Assurance Program Manual Overview........................................................... 3

Purpose ........................................................................................................................................... 3

Scope ............................................................................................................................................. 3

Organization of This Manual ........................................................................................................... 3

Process for Updating ....................................................................................................................... 4

Chapter 1 Construction Quality Assurance Program Overview ................................................. 5

1.1 Definitions and Abbreviations .................................................................................................. 6

1.1.1 Definitions .............................................................................................................................. 6

1.1.2 List of Abbreviations .............................................................................................................. 9

1.2 Specified Level of Quality—Materials and Work Quality .................................................... 10

1.2.1 Materials .............................................................................................................................. 10

1.2.2 Work Quality ........................................................................................................................ 10

1.3 Document and Record Control .............................................................................................. 11

1.3.1 Document Control ............................................................................................................... 11

Table 1.3.1. Document Control References .......................................................................... 12

1.3.2 Records Control .................................................................................................................. 12

Table 1.3.2. Records Control File Categories ........................................................................ 13

Table 1.3.3. Required Documents to be Submitted During Construction ............................. 13

1.4 Management and Staff Responsibilities ............................................................................... 14

1.4.1 Quality Objective ................................................................................................................. 14

1.4.2 Quality Commitment ............................................................................................................ 14

1.4.3 Responsibility and Authority ................................................................................................ 14

1.4.3.a Division of Construction .............................................................................................. 14

1.4.3.b District Construction .................................................................................................... 14

1.4.3.c Division of Engineering Services................................................................................. 14

1.4.3.d Other Divisions ............................................................................................................ 15

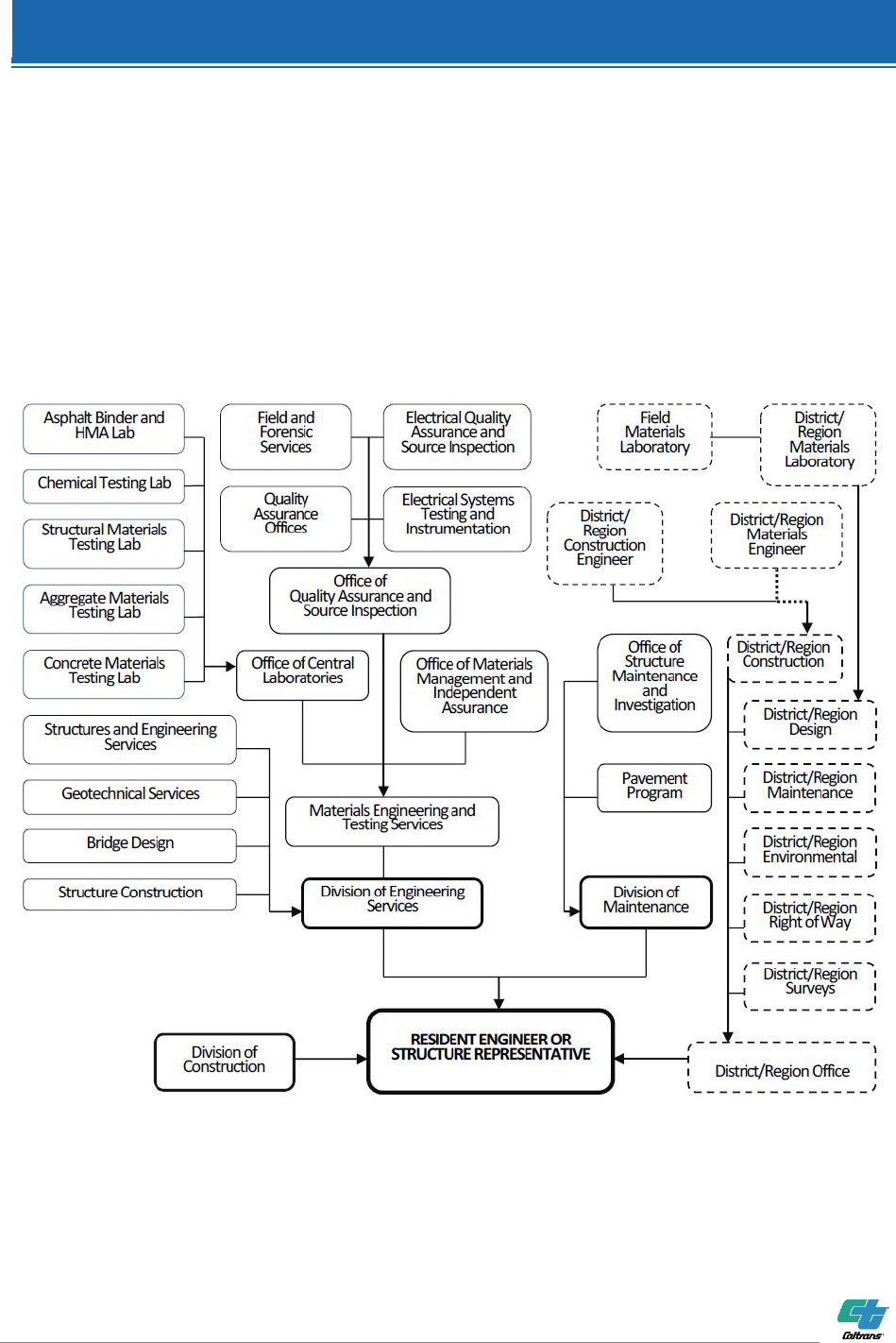

Figure 1.4.1. Support Services Available to Resident Engineer .......................................... 15

Table 1.4.1. Organization Reference .................................................................................... 16

1.4.4 CQAP Process Evaluation .................................................................................................. 16

Table 1.4.2. Process Evaluation References ........................................................................ 16

1.5 Resource Management ........................................................................................................... 17

1.5.1 Competence, Awareness, and Training .............................................................................. 17

Table 1.5.1. Training Policy Reference ................................................................................. 17

1.6 Process Control ....................................................................................................................... 18

1.6.1 Proposed Source of Materials ............................................................................................. 18

1.6.1.a Material Identification and Traceability ........................................................................ 18

Table 1.6.1. Control of Work and Materials References ....................................................... 19

1.6.1.b Handling, Storing, and Transporting ........................................................................... 19

Table 1.6.2. Materials Handling Reference ........................................................................... 19

1.6.1.c Control of Special Processes ...................................................................................... 19

Table 1.6.3. Special Processes References ......................................................................... 20

1.7 Inspection and Testing ........................................................................................................... 21

1.7.1 Role of Resident Engineer .................................................................................................. 21

Table 1.7.1. Engineer Duties References ............................................................................. 21

1.7.2 Quality Control Inspection and Testing ............................................................................... 21

CONSTRUCTION QUALITY ASSURANCE PROGRAM MANUAL

Contents

California Department of Transportation • Division of Construction

Page ii May 2023

Table 1.7.2. Quality Control References ............................................................................... 22

1.7.3 Acceptance Inspection and Testing .................................................................................... 22

1.7.3.a Quality Assurance Methods ........................................................................................ 22

1.7.3.b Acceptance Criteria .................................................................................................... 22

1.7.3.b (1) Manufactured and Fabricated Materials ............................................................. 23

1.7.3.b (2) Job Site-Produced Materials .............................................................................. 23

Table 1.7.3. Materials Acceptance References .................................................................... 23

1.7.4 Independent Assurance ...................................................................................................... 23

Table 1.7.4. Independent Assurance References ................................................................ 25

1.8 Control of Nonconforming Work and Materials ................................................................... 26

Table 1.8.1. Nonconforming Work and Materials References .............................................. 26

1.8.1 Corrective and Preventive Action ....................................................................................... 26

Table 1.8.2. Corrective Work References ............................................................................. 27

1.9 Control of Inspection, Measuring, and Testing Equipment ................................................ 28

Table 1.9.1. Inspection and Testing References .................................................................. 28

1.10 Project Materials Certification ............................................................................................. 29

Table 1.10.1. Materials Certification Reference .................................................................... 29

Chapter 2 Construction Quality Assurance Roadmap Overview ............................................. 30

2.1 Quality Assurance Elements ................................................................................................. 31

2.1.1 Contractor Quality Control .................................................................................................. 31

2.1.2 Department Acceptance Program ...................................................................................... 32

2.1.3 Independent Assurance ...................................................................................................... 32

2.1.4 Dispute Resolution .............................................................................................................. 33

2.1.5 Authorized Laboratories ...................................................................................................... 33

2.1.6 Personnel Qualifications ..................................................................................................... 33

2.2 Specifications .......................................................................................................................... 35

2.2.1 Deciding Between Method and Quality Assurance Specifications ..................................... 35

2.2.1.a Advantages and Disadvantages ................................................................................. 35

2.2.1.a (1) Method Specifications ........................................................................................ 35

Table 2.2.1. Advantages and Disadvantages of Method Specifications ............................... 36

2.2.1.a (2) Quality Assurance Specifications ....................................................................... 36

Table 2.2.2. Advantages and Disadvantages of Quality Assurance Specifications ............. 37

2.2.1.b Choosing the Specification Type ................................................................................ 37

Table 2.2.3. Appropriate Conditions for Using Method Versus Quality Assurance

Specifications ...................................................................................................................... 38

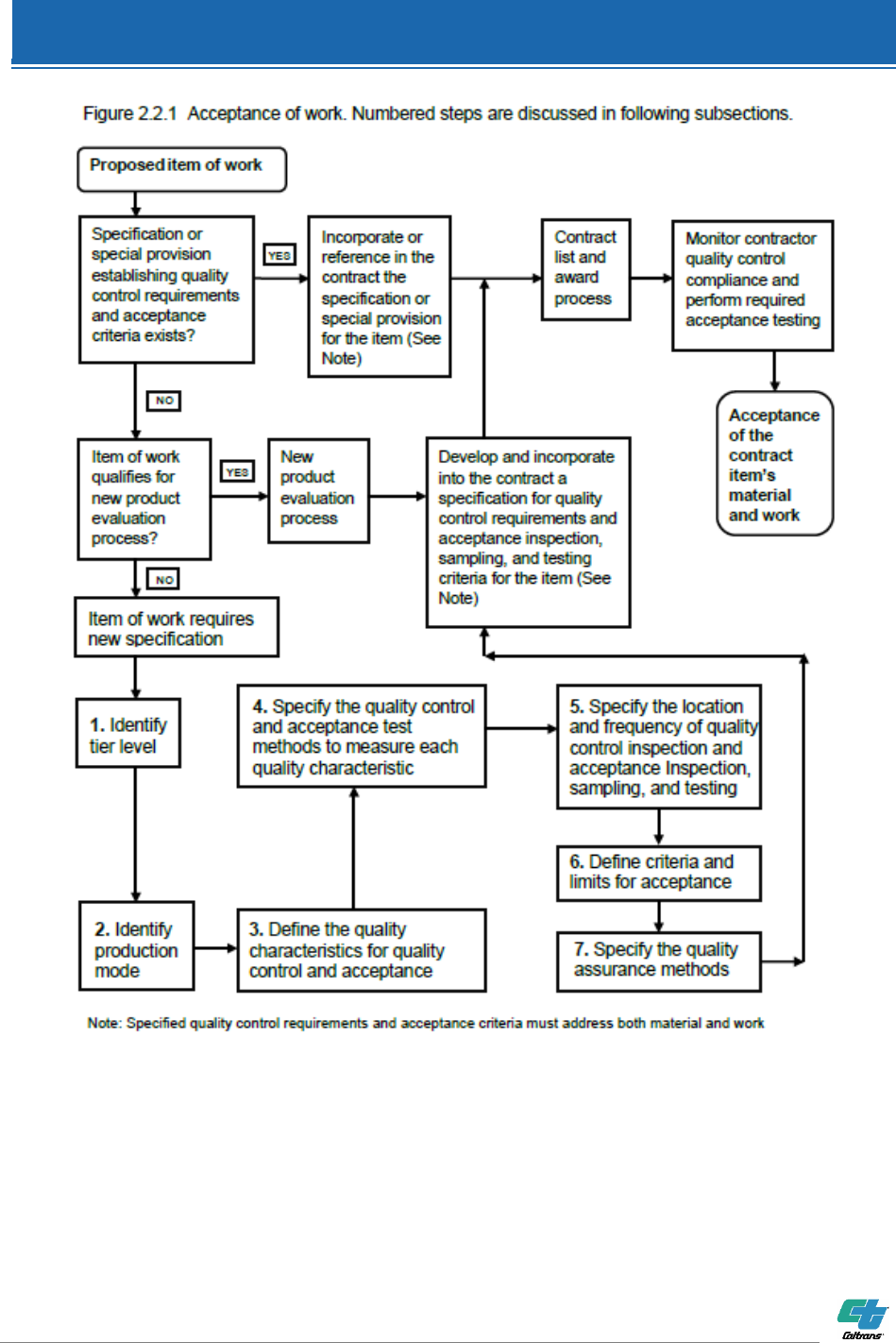

2.2.2 Specification Development Process ................................................................................... 38

Figure 2.2.1. Quality Assurance Specification Development Process .................................. 39

2.2.2.a Step 1—Identify Tier Level ......................................................................................... 39

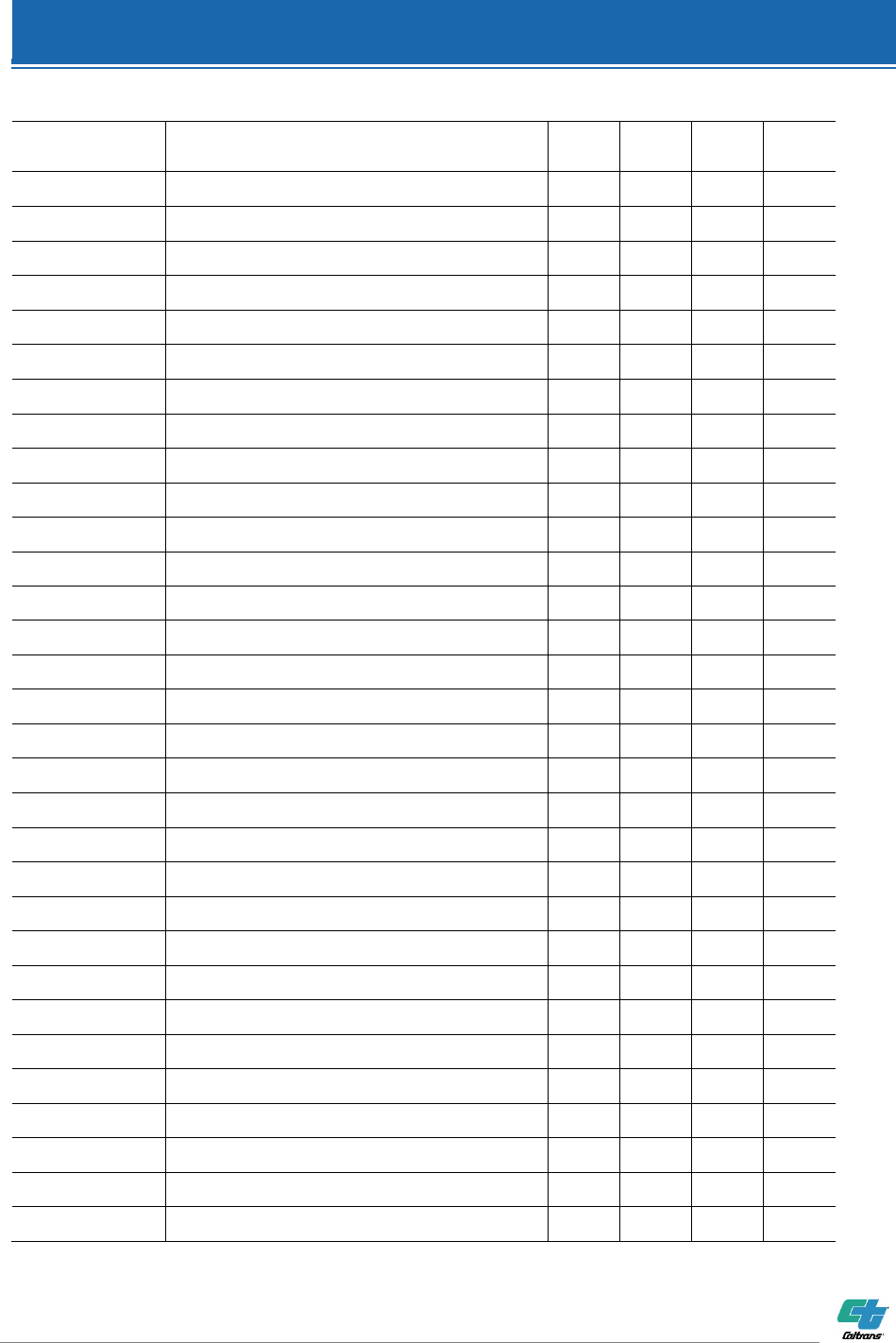

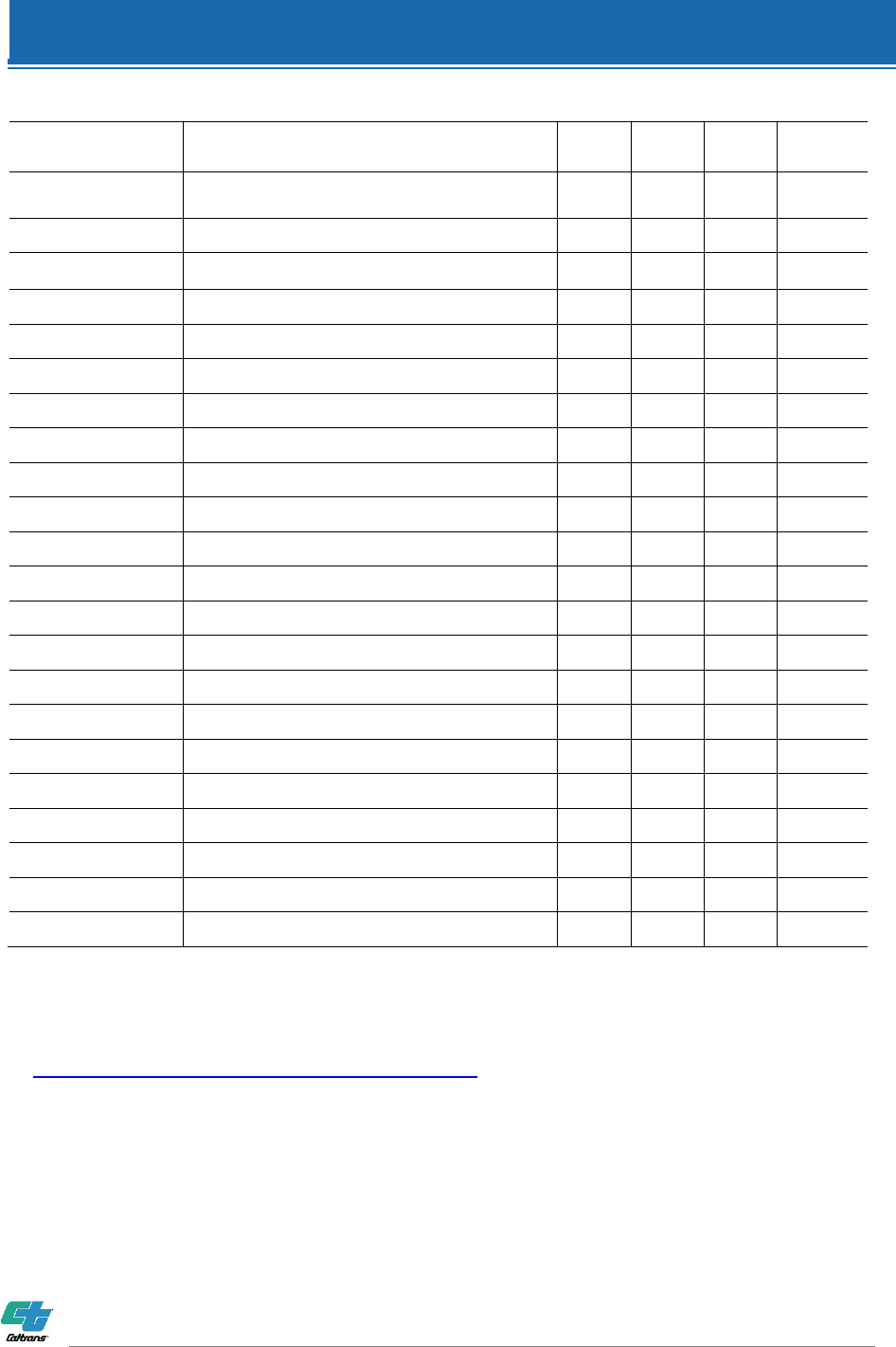

Table 2.2.4. Tier Levels for Contract Items ........................................................................... 40

Table 2.2.5. Standard Specifications Sections with Associated Tier Levels ........................ 41

Table 2.2.5. Standard Specifications Sections with Associated Tier Levels (continued) ..... 42

2.2.2.b Step 2—Identify Production Mode .............................................................................. 42

2.2.2.c Step 3—Define the Quality Characteristics for Quality Control and Acceptance ....... 43

Table 2.2.6. Typical Quality Characteristics for Quality Control and Acceptance ................ 44

2.2.2.d Step 4—Specify the Quality Control and Acceptance Test Methods ......................... 45

2.2.2.e Step 5—Specify the Location and Frequency of Sampling and Testing .................... 45

2.2.2.e (1) Location of Sampling and Testing ...................................................................... 45

2.2.2.e (2) Quality Control Testing Frequency ..................................................................... 46

2.2.2.e (3) Acceptance Testing Frequency .......................................................................... 46

CONSTRUCTION QUALITY ASSURANCE PROGRAM MANUAL

Contents

California Department of Transportation • Division of Construction

May 2023 Page iii

2.2.2.f Step 6—Define the Acceptance Criteria and Acceptance Limits ................................ 46

2.2.2.f (1) Quality Measures ................................................................................................ 46

2.2.2.f (2) Specification Limits ............................................................................................. 46

2.2.2.f (3) Payment Adjustment Schedule ........................................................................... 47

2.2.2.g Step 7—Identify the Quality Assurance Methods to be Specified .............................. 47

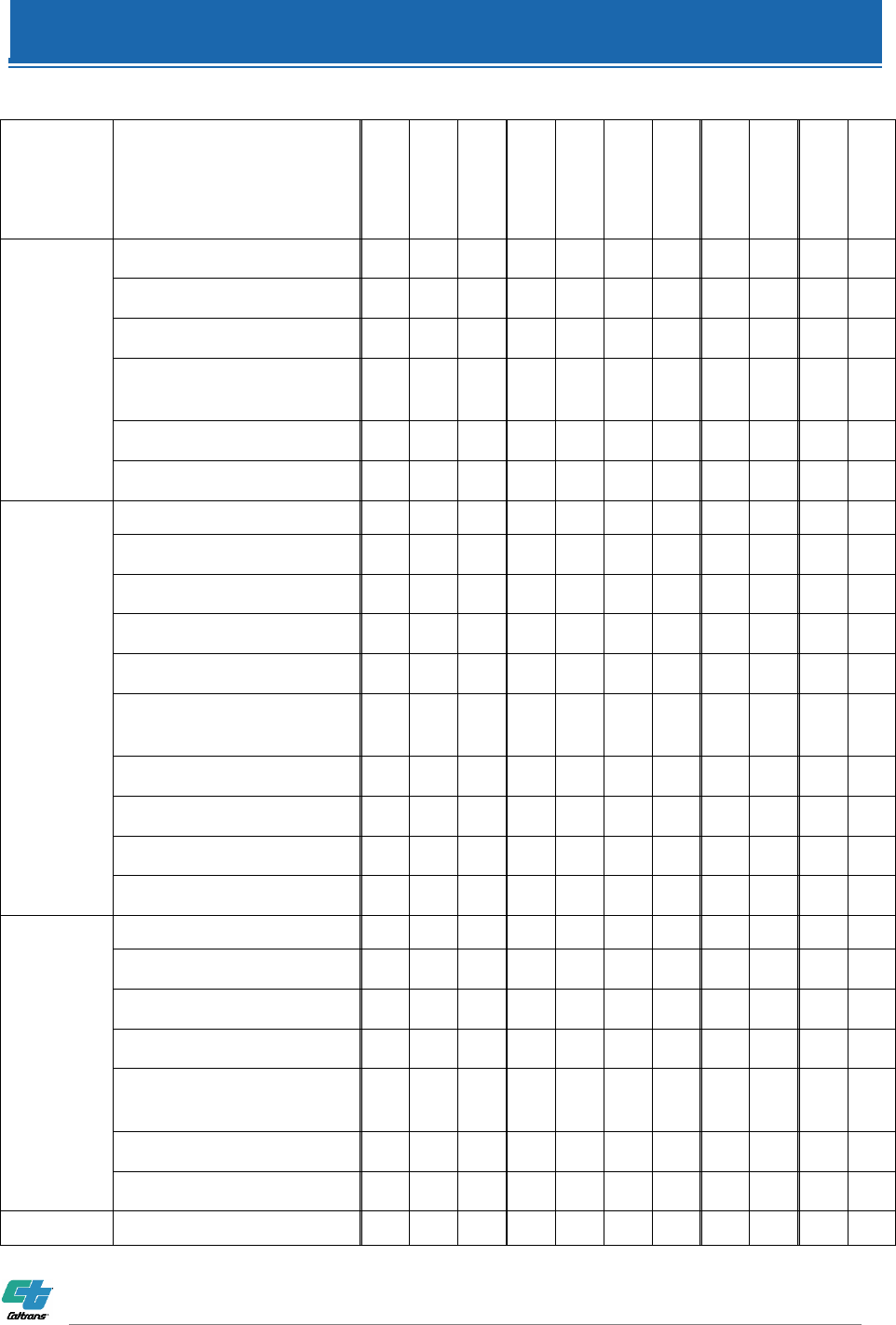

Table 2.2.7. Quality Assurance Method Application Matrix ................................................... 48

2.3 Quality Assurance Methods ................................................................................................... 51

2.3.1 Material Prequalification ...................................................................................................... 51

2.3.1.a Authorized Materials List ............................................................................................. 51

2.3.1.b Aggregate Prequalification Program ........................................................................... 51

2.3.1.c Job Mix Formula Prequalification Program ................................................................. 52

2.3.1.d Proprietary Product or Process ................................................................................... 52

2.3.1.e Products Manufactured to National Quality Standard ................................................. 52

2.3.1.f Commercial Quality Products ...................................................................................... 52

2.3.1.g Caltrans-Furnished Materials ...................................................................................... 53

2.3.2 Qualification Requirements for Facilities, Contractors, and Personnel ............................... 54

2.3.2.a Qualification Requirements for Facilities ..................................................................... 54

2.3.2.a (1) Prefabrication Audit ............................................................................................. 54

2.3.2.a (2) Authorized Facility Audit Listing .......................................................................... 54

2.3.2.a (3) Authorized Laboratory List .................................................................................. 54

2.3.2.a (4) Authorized Laboratory ......................................................................................... 54

Table 2.3.1. Laboratory Authorization Matrix ........................................................................ 55

2.3.2.a (5) Authorized Plant or Facility ................................................................................. 56

2.3.2.b Qualification Requirements for Contractors ................................................................ 56

2.3.2.c Qualification Requirements for Personnel .................................................................. 56

2.3.2.c (1) Sampling, Testing, and Inspection Personnel .................................................... 56

Table 2.3.2. Sampling and Testing Personnel Authorization Matrix ..................................... 57

2.3.2.c (2) Installer, Applicator, or Erector Personnel .......................................................... 57

2.3.3 Submittal Requirements ...................................................................................................... 58

2.3.3.a Designer Review of Construction and Fabrication Working Drawings or Plans ......... 58

2.3.3.b Resident Engineer Review of Construction and Fabrication Process Submittals ...... 58

2.3.3.c Resident Engineer Review of Proposed Job Mix Formulas or Mix Designs ............... 58

2.3.3.d Resident Engineer Review of Proposed Quality Control Procedures ......................... 59

2.3.3.e Engineer Review of Product Data ............................................................................... 59

2.3.3.f Contractor Submittal of Test Samples ........................................................................ 59

2.3.4 Material Sampling and Testing ............................................................................................ 59

2.3.4.a Pre-Production, Initial or Stockpile .............................................................................. 59

2.3.4.b Quality Control Sampling and Testing ........................................................................ 59

2.3.4.b (1) Quality Control Sampling and Testing for Process Control ................................ 60

2.3.4.b (2) Quality Control Sampling and Testing for Acceptance ....................................... 60

2.3.4.c Verification Sampling and Testing............................................................................... 60

2.3.4.d Programmatic Quality Assurance Inspection and Testing at the Job Site .................. 61

2.3.4.e Programmatic Assessment ......................................................................................... 61

2.3.4.f Acceptance Sampling and Testing.............................................................................. 61

2.3.5 Certificate of Compliance .................................................................................................... 62

2.3.5.a Certificate of Compliance from Producer .................................................................... 62

2.3.5.b Certificate of Compliance from Producer with Test Results ....................................... 62

2.3.6 Material and Engineering Inspection ................................................................................... 63

2.3.6.a Material Inspection ...................................................................................................... 63

2.3.6.a (1) Quality Control Inspection ................................................................................... 63

CONSTRUCTION QUALITY ASSURANCE PROGRAM MANUAL

Contents

California Department of Transportation • Division of Construction

Page iv May 2023

2.3.6.a (2) Verification Inspection ........................................................................................ 63

2.3.6.a (3) Acceptance Inspection ....................................................................................... 63

2.3.6.a (4) Pre-Production Meetings .................................................................................... 64

2.3.6.a (5) Pre-Production Trial Mockup .............................................................................. 64

2.3.6.b Engineering Inspection ............................................................................................... 64

2.3.7 Warranty Provisions ............................................................................................................ 65

2.3.7.a Material and Work Quality Warranty ........................................................................... 65

2.3.7.b Performance Warranty ................................................................................................ 65

2.3.7.c Guarantee ................................................................................................................... 65

Chapter 3 Construction Quality Assurance Long-Range Plan Overview ................................ 66

3.1 Long-Range Objective—Construction Quality Assurance Database................................ 66

3.1.1 Data Interchange for Materials Engineering, METS ............................................................ 66

3.1.1.a Construction Quality Assurance Database Requirements ......................................... 67

3.1.1.b Team Culture and Innovation ..................................................................................... 67

3.1.1.c Environmental Product Declaration ............................................................................ 67

3.1.2 Construction Quality Assurance Database, Division of Construction .................................. 67

3.1.2.a Contract Payments ..................................................................................................... 68

3.1.2.b Construction Document Management System ........................................................... 68

3.1.2.c Data Visualization and Reporting Systems ................................................................ 68

3.1.3 Construction Quality Assurance Database—Pavement Program ...................................... 69

3.1.4 Construction Quality Assurance Database—Structural Construction ................................ 70

3.1.4.a Project Data Management System (ProDMS) ............................................................ 70

3.1.4.b Future Development on ProDMS................................................................................ 70

3.2 Long-Range Objective—System-Based Acceptance Process ........................................... 71

3.2.1 Pre-Approved Source ......................................................................................................... 71

3.2.2 Unapproved Source ............................................................................................................ 71

3.2.3 Laboratory Testing .............................................................................................................. 72

3.2.4 Material Approval and Delivery ........................................................................................... 72

3.2.5 Field Release of Manufactured Items ................................................................................. 72

3.2.6 Project-Level Documentation .............................................................................................. 72

3.2.7 Final Materials Certification................................................................................................. 73

3.3 Long-Range Objective—Performance Specifications......................................................... 74

3.3.1 Concrete Pavements ........................................................................................................... 75

3.3.2 Asphalt Pavements .............................................................................................................. 75

3.3.2.a Non-Performance-Related Specifications .................................................................. 76

3.3.2.a (1) Advantages and Requirements of Non-Performance-Related Specifications ... 76

3.3.2.a (2) Status of Non-Performance-Related Specifications ........................................... 77

3.3.2.b Performance-Related Specifications .......................................................................... 77

3.3.2.b (1) Distinguishing Features of Performance-Related Specifications ....................... 78

3.3.2.b (2) Status of Performance-Related Specifications ................................................... 78

3.3.2.c Quality Assurance Program Changes ........................................................................ 78

3.4 Long-Range Objective—Risk-Based Acceptance Criteria ................................................. 79

3.4.1 Analysis Acceptance Limits ................................................................................................ 79

3.4.2 Analysis to Confirm Acceptance Plan Risks ....................................................................... 80

Appendixes ....................................................................................................................................... 82

Appendix A: Caltrans Quality Assurance Documents ............................................................... 83

Appendix B: Caltrans Quality Assurance Program Bulletin ..................................................... 84

Appendix C: Caltrans Deputy Directives ..................................................................................... 86

CONSTRUCTION QUALITY ASSURANCE PROGRAM MANUAL

Introduction

California Department of Transportation • Division of Construction

May 2023 Page 1

Introduction

For many years, departments of transportation (DOTs) performed testing and inspection to

verify the quality of materials used in highway construction. During those years, DOTs were

the sole testing and inspection authority. Later, as some of the testing duties were shifted to

the contractor, the DOTs continued performing tests for acceptance or verification. The

contractor testing was then referred to as quality control, while the DOT testing and inspection

were termed quality assurance.

In the past two decades, the use of alternative project delivery methods challenged the

traditional quality management approach where the contractor performed quality control while

the owner conducted quality assurance. This caused a shift in perspective regarding quality

assurance. For the Federal Highway Administration (FHWA), construction quality assurance is

not a slogan. It is a systematic approach to attain the constructed quality of each Federal-aid

project. As Figure 1 illustrates, a complete Quality Assurance Program includes the six core

elements of:

• Contractor Quality Control

• Agency Acceptance

• Independent Assurance

• Dispute Resolution

• Laboratory Qualification and Accreditation

• Personnel Qualification and Certification

Figure 1. FHWA Six Core Elements of Quality Assurance Program

CONSTRUCTION QUALITY ASSURANCE PROGRAM MANUAL

Introduction

California Department of Transportation • Division of Construction

Page 2 May 2023

Quality construction is fundamental to meeting the mission of the California Department of

Transportation (Caltrans), and quality assurance is the primary means by which Caltrans

confirms the quality of constructed highway projects.

Quality assurance encompasses all materials and construction activities on a project and

directly affects the service life of a transportation facility. The elements of an acceptable quality

assurance program include quality control by the contractor, acceptance testing and inspection

by Caltrans, independent assurance, qualified personnel, accredited laboratories, and a

dispute resolution process. These elements work together to assure an effective quality

assurance program. Any elements missing from the program increase the risks associated

with the project, such as a reduced service life.

The Construction Quality Assurance Program (CQAP), developed by Caltrans for highway

construction projects, adheres to the quality assurance requirements outlined by the Federal

Highway Administration (FHWA) in the Code of Federal Regulations, Title 23, Section 637 (23

CFR 637), “Construction Inspection and Approval”; 23 CFR 637 Subpart B, “Quality Assurance

Procedures for Construction,”; 23 CFR 637.205, “Policy,” and 23 CFR 637.207, “Quality

Assurance Program.”

The role of the CQAP is to provide confidence that the quality of the materials and work quality

incorporated into all highway construction projects conforms to the requirements of the plans

and specifications.

CONSTRUCTION QUALITY ASSURANCE PROGRAM MANUAL

Introduction

California Department of Transportation • Division of Construction

May 2023 Page 3

Construction Quality Assurance Program Manual Overview

Purpose

Completed projects are tangible products by which Caltrans is measured in the delivery of its

programs. The public ultimately defines the success of Caltrans’ performance based on these

projects.

Caltrans requires consistent quality construction in all its projects. As a result, over the years,

Caltrans has developed procedures and methods to make sure that every construction project

achieves the desired level of quality for both materials and work. The responsibility for

construction quality has been shared by various functional groups, resulting in the distribution

of quality-related policies, procedures, and guidelines throughout Caltrans, with no single,

consolidated document available as a guide for all quality-related requirements.

Scope

This manual documents the CQAP by identifying existing quality related requirements from all

applicable Caltrans policies, procedures, and guidance documents. See Appendix A, “Caltrans

Quality Assurance Documents.” This manual also demonstrates compliance with 23 CFR 637.

The provisions of this manual apply to design-bid-build projects and projects under a

construction manager general contractor (CMGC) or a job order contracting agreement. The

provisions do not apply to projects for which Caltrans has entered into a public-private

partnership or a design-build agreement. The Caltrans document, “Design-Build Quality

Manual Template,” provides guidance to design-builders regarding quality assurance. For

alternate project delivery methods, Caltrans retains responsibility for acceptance. The

implementing agency may use its own program when authorized by Caltrans; however,

Caltrans retains authority for the project and performs independent quality assurance to make

sure that the implementing agency’s quality assurance activities result in projects being

developed in accordance with Caltrans standards, policies, practices, and the quality control

plan provided by the project sponsor.

This manual does not repeat information contained in other manuals but references where the

inspection, acceptance testing, and independent assurance requirements are found for

materials used in highway construction.

Organization of This Manual

• Chapter 1, “Construction Quality Assurance Program,” describes the CQAP activities

Caltrans performs to achieve the specified quality for constructed highway facilities. These

activities include control of documents and records, management responsibilities, resource

management, process control, inspection and testing, control of nonconforming work,

control of testing and measuring equipment, and project materials certification.

• Chapter 2, “Construction Quality Assurance Roadmap,” describes the six major

components of the CQAP; presents the route to developing quality assurance

specifications for materials, work quality, products, and services; summarizes the various

quality assurance methods Caltrans uses; and provides guidance to determine which

quality assurance methods are needed to achieve a level of quality assurance appropriate

to the application of a contract item of work, and severity of the consequences of its failure.

• Chapter 3, “Construction Quality Assurance Long-Range Plan,” recommends and

describes a potential long-range plan for improvements to the CQAP. The long-range plan

includes establishing a construction quality assurance database, adopting a system-based

acceptance process, implementing performance specifications, and adopting risk-based

CONSTRUCTION QUALITY ASSURANCE PROGRAM MANUAL

Introduction

California Department of Transportation • Division of Construction

Page 4 May 2023

acceptance criteria based on use of performance-related specifications, risk-based

acceptance, and system-based acceptance. Development and implementation of a

materials management system construction quality assurance database is the primary

recommendation to improve the efficiency and quality of the CQAP.

Process for Updating

The Division of Construction issues Quality Assurance Program Bulletins (QAPBs), as shown

in Appendix B, “Caltrans Quality Assurance Program Bulletin” to communicate procedure and

policy changes. From time to time, QAPBs are incorporated into this manual. QAPBs

supersede any conflicting information, guideline, or instruction in the manual. If a policy

contained in this manual is unclear or has been superseded, and a QAPB has not been issued

covering the changed policy, notify the Division of Construction, Publications Unit.

CONSTRUCTION QUALITY ASSURANCE PROGRAM MANUAL

Chapter 1—Construction Quality Assurance Program

California Department of Transportation • Division of Construction

May 2023 Page 5

Chapter 1

Construction Quality Assurance Program

Overview

The Construction Quality Assurance Program (CQAP) includes an acceptance program for

materials and work quality, an independent assurance program, and preparation of a project

materials certification. Consistent with the Code of Federal Regulations Title 23, Section 637

(23 CFR 637), “Construction and Inspection Approval,” the CQAP assures “that the materials

and workmanship incorporated into each federal-aid highway construction project on the

National Highway System are in conformity with the requirements of the approved plans and

specifications, including approved changes.” The CQAP is also applicable to all California

Department of Transportation (Caltrans) projects on the State Highway System. However, the

CQAP is not applicable to projects for which Caltrans has entered into a public-private

partnership or a design-build agreement.

Chapter 1 describes CQAP-related organizational roles and responsibilities, and the policies

and procedures designed to assure that specified construction materials and work quality

incorporated into each project are acceptable and in conformance with the contract

documents. The chapter is organized into 10 sections:

1. Definitions and Abbreviations

2. Specified Level of Quality—Materials and Work Quality

3. Document and Record Control

4. Management and Staff Responsibilities

5. Resource Management

6. Process Control

7. Inspection and Testing

8. Control of Nonconforming Work and Materials

9. Control of Inspection, Measuring, and Testing Equipment

10. Project Materials Certification

Section 1 addresses the definitions and abbreviations associated with the specialized

vocabulary in quality assurance programs.

Sections 2 through 10 are based in part on the International Organization for Standardization

(ISO) 9001, “Quality Management Systems.” ISO 9001 lists 20 quality management elements

that must be addressed in a quality assurance program. These sections demonstrate the

CQAP’s conformance with the ISO 9001 elements applicable to transportation construction.

Some ISO 9001 elements are not addressed in the CQAP because they reflect the

manufacturing-related origins of the ISO 9000 series and a literal application to transportation

construction is not appropriate.

CONSTRUCTION QUALITY ASSURANCE PROGRAM MANUAL

Chapter 1—Construction Quality Assurance Program

California Department of Transportation • Division of Construction

Page 6 May 2023

1.1 Definitions and Abbreviations

The terms related to the Caltrans quality assurance program are defined in this section.

1.1.1 Definitions

acceptance: The process of deciding if the material and work quality meet contract

requirements.

acceptance program: All factors that comprise Caltrans’ determination of the product’s

quality as specified in the contract requirements. These factors include verification

sampling, testing, and inspection, and may include results of quality control sampling and

testing. Refer to 23 CFR 637, Subpart B, “Quality Assurance Procedures.”

acceptance tests: Defined in Section 6-102, “Types of Sampling and Testing,” of the

Construction Manual as “tests performed on samples from the materials that will be

incorporated into the work.”

acceptance sampling and testing: Sampling, testing, and assessing test results to

determine whether the quality of produced material or construction meets the terms of the

specifications.

accredited laboratories: Laboratories that are accredited by Caltrans in accordance with the

requirements of the Caltrans Independent Assurance Manual (IAM), Section 2.4,

“Laboratory Accreditation,” for performing tests on aggregates, asphalt concrete materials,

embankment and soils, and cementitious concrete materials.

authorized laboratories: Independent testing laboratory: (1) not employed or compensated

by any subcontractor or subcontractor’s affiliate providing other services for the contract,

and (2) authorized by Caltrans. Refer to the Standard Specifications. This includes

laboratories accredited in accordance with Section 2.4 of the IAM, as well as laboratories

authorized using other methods.

construction manager or general contractor: A project delivery method in which the

contractor is selected during the design process and makes input to the design regarding

constructability, cost engineering, and value analysis reviews. Once the design is

complete, the same entity may build the project as the general contractor. The construction

manager or general contractor delivery method assumes the contractor will perform a

significant amount of the construction work.

construction manager-at-risk: A project delivery method similar to the construction manager

or general contractor method, except the construction manager does not perform any of

the construction work.

design-bid-build: A project delivery method for which the design phase and the construction

phase are done by separate entities.

design-build: A project delivery method for which the design phase and construction phase of

the project are both awarded to a single entity.

documentation: Proof in the form of detailed records or charts supporting the effectiveness of

a quality control system.

fabricated: Custom-made under controlled conditions to Caltrans specifications.

implementing agency: The entity charged with the successful completion of each project

component as defined in California Government Code Section 14529 (b). Refer to Deputy

CONSTRUCTION QUALITY ASSURANCE PROGRAM MANUAL

Chapter 1—Construction Quality Assurance Program

California Department of Transportation • Division of Construction

May 2023 Page 7

Directive 090-R1, “Funding of Quality Management Work on State Highway Projects,”

December 21, 2018, included in Appendix C.

independent assurance program: Activities that are an unbiased and independent

evaluation of all the sampling and testing procedures used in the acceptance program.

Refer to 23 CFR 637.

independent quality assurance: The activities performed by Caltrans at a project level to

verify that the implementing agency’s quality assurance activities result in projects being

delivered in accordance with Caltrans standards, policies, and practices, and the quality

control plan provided by the project sponsor. Refer to Deputy Directive 090-R1, “Funding

of Quality Management Work on State Highway Projects,” December 21, 2018, included in

Appendix C.

job order contracting: Also known as indefinite delivery or indefinite quantity contracting

provides for an indefinite quantity of construction services whose performance and delivery

scheduling are determined by issuing work orders with the contractor during a fixed period

of time. It is an on-call construction contract through a master agreement, not a purchase

order or service contract.

manufactured: Mass-produced under controlled conditions to standard industry

specifications.

process control: The method for keeping a process within boundaries; the act of minimizing

the variation of a process. Refer to American Society for Quality, “Quality Glossary.”

public-private partnership: Comprehensive lease agreement between Caltrans, or regional

transportation agencies, and public or private entities for transportation projects.

qualified laboratories: Laboratories that are capable as defined by appropriate programs

established by Caltrans. As a minimum, the qualification program must include provisions

for checking test equipment and the laboratory, and must keep records of calibration

checks. Refer to 23 CFR 637. Caltrans uses “accredited laboratories” as an equivalent to

the term “qualified laboratories.”

qualified sampling and testing personnel: Capable personnel, as defined by appropriate

programs established by Caltrans. Refer to 23 CFR 637.

qualified tester: Personnel qualified by successfully completing the process in the

Independent Assurance Manual, Section 2.3, “Tester Qualification,” or as defined in the

plans and specifications.

quality: (1) the degree or grade of excellence of a product or service, (2) the degree to which

a product or service satisfies the needs of a specific customer, and (3) the degree to which

a product or service conforms to a given requirement.

quality assurance: All planned and systematic actions necessary to provide confidence that a

product, facility, or service will satisfy given quality requirements. Refer to 23 CFR 637.

quality control: Actions and considerations necessary to assess and adjust production and

construction processes to control the level of quality produced in the end product or facility,

and to fulfill specified requirements.

quality control plan: Contractor's plan to confirm quality control. Refer to Caltrans Standard

Specifications glossary.

specifications: Caltrans Standard Specifications, revised Standard Specifications, and

special provisions.

CONSTRUCTION QUALITY ASSURANCE PROGRAM MANUAL

Chapter 1—Construction Quality Assurance Program

California Department of Transportation • Division of Construction

Page 8 May 2023

verification: The process of determining or testing the truth or accuracy of a test result by

examining the data and providing objective evidence. Caltrans applies this process as part

of the acceptance program by inspection, sampling, and testing to determine the accuracy

of the contractor’s test results.

verification sampling and testing: Sampling and testing performed to validate the quality of

the product. Refer to 23 CFR 637.

CONSTRUCTION QUALITY ASSURANCE PROGRAM MANUAL

Chapter 1—Construction Quality Assurance Program

California Department of Transportation • Division of Construction

May 2023 Page 9

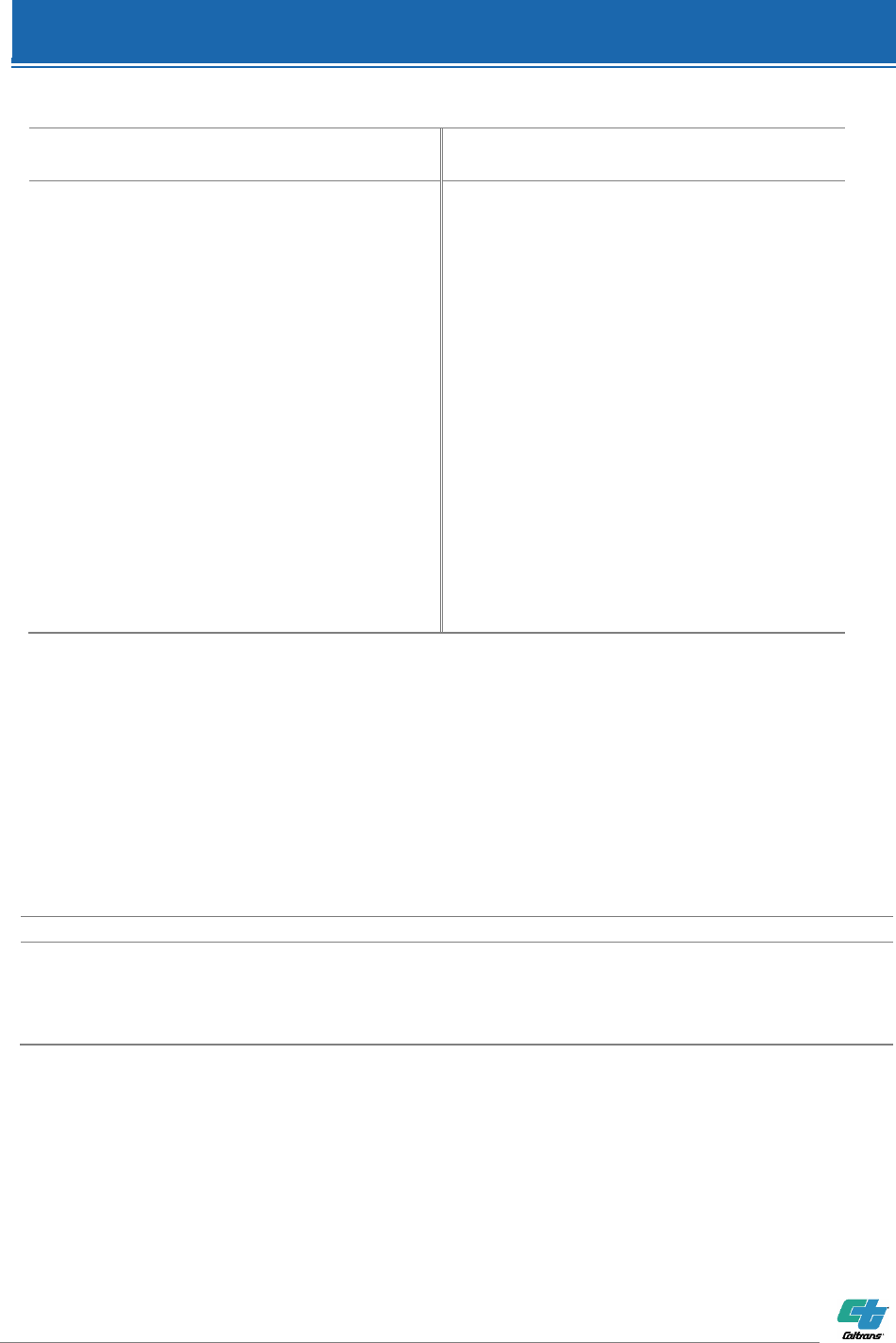

1.1.2 List of Abbreviations

The following abbreviations and their definitions are used in this manual.

Abbreviation

Description

AASHTO

American Association of State Highway and Transportation Officials

AFAL

Authorized Facility Audit List

AISC

American Institute of Steel Construction

ASTM

American Society for Testing and Materials

BCRP

Bridge Construction Records and Procedures Manual

CAPE

Contract Administration Process Evaluation

CFR

Code of Federal Regulations

CQAP

Construction Quality Assurance Program (Caltrans)

DES-SC

Division of Engineering Services, Structure Construction

DIME

Data Interchange for Materials Engineering

DOT

Department of Transportation

FHWA

Federal Highway Administration

FSR

Feasibility Study Report

HMA

Hot Mix Asphalt

IAM

Independent Assurance Manual (Caltrans)

JMF

Job Mix Formula

METS

Materials Engineering and Testing Services

MPQP

Material Plant Quality Program

OCL

Office of Central Laboratories

OMMIA

Office of Materials Management and Independent Assurance

OQASI

Office of Quality Assurance and Source Inspection

PaveM

Pavement Management System (Caltrans)

PBS

Performance-Based Specifications

PRS

Performance-Related Specifications

QASI Manual

Quality Assurance and Source Inspection Manual

QMS

Quality Management System

SIAD

Statewide Independent Assurance Database

CONSTRUCTION QUALITY ASSURANCE PROGRAM MANUAL

Chapter 1—Construction Quality Assurance Program

California Department of Transportation • Division of Construction

Page 10 May 2023

1.2 Specified Level of Quality—Materials and Work Quality

The CQAP includes specifications and plans that describe the quality requirements for all

material and work to be incorporated into a project, and the acceptance criteria by which

Caltrans will verify conformance with the quality requirements. Material and work quality

requirements are established in the design process and reflect the standards necessary to

make sure that the material or item will function as designed. During construction, tests and

inspections evaluate the acceptability of the material and work based on the acceptance

criteria.

1.2.1 Materials

The quality requirements for materials are contained in the: (1) Caltrans Standard

Specifications and project special provisions; (2) contract plans, and (3) change orders. These

documents include or reference the acceptance criteria for determining if the prescribed quality

for materials has been met. For example, Section 19-3.02C, “Structure Backfill,” of the 2022

Standard Specifications, requires that structure backfill complies with the grading requirement

of 100 percent passing the 3-inch sieve.

1.2.2 Work Quality

The requirements for work quality are contained in the Caltrans Standard Specifications,

project special provisions and in the plans or change orders. For example, Section 73-3.03,

“Construction,” of the Standard Specifications, requires that “The finished surface must not

vary more than 0.02 foot from a 10-foot straightedge …”

CONSTRUCTION QUALITY ASSURANCE PROGRAM MANUAL

Chapter 1—Construction Quality Assurance Program

California Department of Transportation • Division of Construction

May 2023 Page 11

1.3 Document and Record Control

Activities affecting quality are prescribed by and accomplished in accordance with documented

instructions, procedures, and drawings. These documents also include appropriate

quantitative or qualitative acceptance criteria for determining that the activities have been

satisfactorily accomplished.

The following types of documents are used in the CQAP:

• Documents that provide consistent information, both internally and externally, about

Caltrans’ CQAP. Such documents are referred to as quality manuals.

• Documents that describe how the CQAP is applied to a specific product, project, or

contract. Such documents are referred to as quality plans.

• Documents stating requirements. Such documents are referred to as specifications.

• Documents stating recommendations or suggestions. Such documents are referred to as

guidelines.

• Documents that provide information about how to perform activities and processes

consistently. Such documents include documented procedures, work instructions, and

drawings.

• Documents that provide objective evidence of activities performed or results achieved.

Such documents are referred to as records.

1.3.1 Document Control

The CQAP includes procedures to control the issuance of documents, including changes, that

prescribe all activities affecting quality. These procedures assure that documents, including

changes, are: (1) reviewed for adequacy, (2) approved for release by authorized personnel,

and (3) distributed for use where the prescribed activity is performed.

Preparing, issuing, and updating or revising documents that specify quality requirements or

prescribe activities affecting quality are controlled processes that assure that correct, up-to-

date documents are used. The document control system assures distribution and availability of

the latest authorized documents to all required users before the start of work.

• Program level documents, such as the Construction Manual and changes to it, are

reviewed for adequacy and authorized for release by appropriate division personnel. For

example, the Division of Construction makes changes in policy to the Construction Manual

as need arises. Policy changes are incorporated into the Construction Manual and

announced in manual change transmittals, which the Division of Construction reviews and

controls. Another useful guide is the Quality Assurance and Source Inspection (QASI)

Manual, which is controlled by the Office of Quality Assurance and Source Inspection

(OQASI) (see Appendix A for reference link).

• Project level documents, such as plans and specifications, are controlled and issued by

district office engineers as part of the construction contract for a project. Changes to these

documents after project award are controlled by a change order process.

Table 1.3.1. lists supporting documentation.

CONSTRUCTION QUALITY ASSURANCE PROGRAM MANUAL

Chapter 1—Construction Quality Assurance Program

California Department of Transportation • Division of Construction

Page 12 May 2023

Table 1.3.1. Document Control References

Title

Chapter/Section

Description

Construction Manual

Chapter 1, Section 0

Construction Manual Overview

Construction Manual

Chapter 5, Section 1

Project Records and Reports

Construction Manual

Chapter 5, Section 3

Change Orders

Construction Manual

Chapter 9

Projects Sponsored by Others

QASI Manual

Sections 5, 6, 11, 40, 47, 49, 50,

52, 55, 75, 86, 90, 99

Quality Control Plan Review

QASI Manual

Sections 1, 5, 11, 40, 46, 47, 49,

50, 51, 52, 55, 56, 59, 60, 65, 75,

83, 86

Shop Drawing Review

BCRP Vol. 1

Bridge Construction Memo C-6

Required Documents to be Submitted

During Construction

Note: See Appendix A for the reference manuals

1.3.2 Records Control

The CQAP includes procedures that verify that sufficient records are maintained to furnish

evidence of activities affecting quality. At a minimum, inspection and test records must identify

the inspector, tester, or data recorder, the type of observation, the results, the acceptability,

and the action taken in connection with any deficiencies noted. Records must be identifiable

and retrievable. Records retention requirements, such as duration, location, and assigned

responsibility, are established. Refer to Section 5-104C, “Disposition of Construction Project

Records” of the Construction Manual for the details.

Quality records describe the work involved and contain evidence that work items met the

requirements of the plans and specifications; sampling and testing personnel, procedures and

equipment were properly certified or accredited, and corrective action was taken for any

nonconforming conditions. Records generated for the project by Caltrans, consultants,

contractors, subcontractors, and suppliers represent an important and integral part of each

construction project. Contractors are required to maintain quality records as evidence of their

activities and those of their subcontractors and suppliers.

Resident engineers and structure representatives maintain records at the projects during the

construction phase. After project closeout, those records are transferred to district archives

and retained in accordance with record retention schedules. As-built plans for all projects on

the State Highway System are submitted to the document retrieval system (DRS) unit at the

Division of Design. The official as-built plans are stored in DRS. Structure-related documents

are submitted to headquarters Structure Construction for distribution to other pertinent units for

record keeping. Refer to BCRP, Vol. 1, Bridge Construction Memo C-6, “Required Documents

to be Submitted During Construction.”

Required quality records are indexed, filed, readily retrievable for authorized personnel,

maintained, stored to minimize deterioration and prevent damage or loss, and archived

according to applicable written procedures. Refer to Table 1.3.2 for examples of quality

records indexed and filed in the uniform filing system.

CONSTRUCTION QUALITY ASSURANCE PROGRAM MANUAL

Chapter 1—Construction Quality Assurance Program

California Department of Transportation • Division of Construction

May 2023 Page 13

Table 1.3.2. Records Control File Categories

File

Category

File Description

File

Category

File Description

9

Welding

39

Materials Testing Qualification of

Employees

11

Information Furnished at Start of

Project

40

Field Laboratory Assistant Reports

to Resident Engineer

29

Materials Information and

Preliminary Tests

41

Report of Inspection of Material

30

Basement Soil Test Results

42

Material Plants

31

Notice of Materials to Be Used

43

Concrete and Reinforcing Steel

32

Notice of Materials to be Inspected

at the Job Site

45

Resident Engineer’s Daily Reports

34

Treated Base

46

Assistant Resident Engineer’s

Daily Reports

35

Hot Mix Asphalt

47

Drainage Systems

36

Concrete, other than structure

items

49

Change Orders

37

Initial Tests and Acceptance Tests

63

Project Completion Documents

38

Quality Control

Most project records are distributed to the project field office for current projects, or the district

archives for completed projects for recordkeeping. An example of a document review would be

to determine if qualified testers were used to perform tests. The first step would be to sample

records from Category 37, “Initial Tests and Acceptance Tests,” to obtain the names of testers.

Then review records from Category 39, “Materials Testing Qualification of Employees,” and

the Statewide Independent Assurance Database (SIAD), to determine that testers are

qualified. For more information, refer to the Construction Manual.

Table 1.3.3. lists supporting documentation.

Table 1.3.3. Required Documents to be Submitted During Construction

Title

Chapter/Section

Description

Construction Manual

Chapter 5, Section 1

Project Records and Reports

BCRP Vol. 1

Bridge Construction Memo C-6

Required Documents to be Submitted

During Construction

QASI Manual

Section 1-A.07.2

OQASI Uniform Filing System for

Project Specific Documents

Note: See Appendix A for the reference manuals

CONSTRUCTION QUALITY ASSURANCE PROGRAM MANUAL

Chapter 1—Construction Quality Assurance Program

California Department of Transportation • Division of Construction

Page 14 May 2023

1.4 Management and Staff Responsibilities

1.4.1 Quality Objective

Caltrans’ strategic goals include:

• Safety first

• Cultivate excellence

• Strengthen stewardship and drive efficiency

1.4.2 Quality Commitment

Caltrans is committed to providing adequate technical, administrative, and managerial services

to support each construction project so that it is completed to the specified level of quality, and

when placed in operation, provides a safe, reliable, easily maintained facility that fulfills the

intended function, and meets all applicable statutory and regulatory requirements.

1.4.3 Responsibility and Authority

Caltrans’ key organizations and management positions responsible for managing, performing,

and verifying work affecting quality are described in Chapter 1, “Caltrans Construction

Organization,” of the Construction Manual.

1.4.3.a Division of Construction

• The chief of the Division of Construction, located in headquarters, leads the CQAP to

deliver quality transportation products and services.

• Headquarters Construction office chiefs and staff, and Construction field coordinators

assist with contract administration processes and reviews.

1.4.3.b District Construction

• The district and regional Construction division chief or district Construction deputy director

is responsible for implementing the CQAP in each region or district.

• District Construction engineers are responsible for making sure resident engineers are

adequately trained, verifying that materials and work comply with plans and specifications,

and maintaining project quality records.

• District materials engineers are responsible for district and field materials laboratories.

• The resident engineer assigned to each project is the onsite Construction representative

and is responsible for contract administration, construction engineering, and the

acceptance of all materials and work quality on each assigned project. The resident

engineer makes sure that contractor and state staff whose test results are used in the

acceptance decision are certified in accordance with the Independent Assurance Program.

1.4.3.c Division of Engineering Services

• The Division of Engineering Services, Structure Construction (DES-SC) is responsible for

technical control of structure work and has ultimate responsibility and authority for

decisions relating to the structural adequacy of contract work on structures. DES-SC

engineers are assigned to all districts to provide field engineering for structures. The

district may request that the assigned structure representative act as the resident engineer

on projects where structure work predominates.

CONSTRUCTION QUALITY ASSURANCE PROGRAM MANUAL

Chapter 1—Construction Quality Assurance Program

California Department of Transportation • Division of Construction

May 2023 Page 15

• Materials Engineering and Testing Services (METS) conducts specialized laboratory and

field testing, provides source inspections, audits suppliers and fabricators, and gives expert

advice on all phases of transportation engineering involving materials and manufactured

products. METS also provides technical expertise for the development of statewide

standards, procedural guidelines, and manuals. Furthermore, the independent assurance

program has been centralized and is administered by METS.

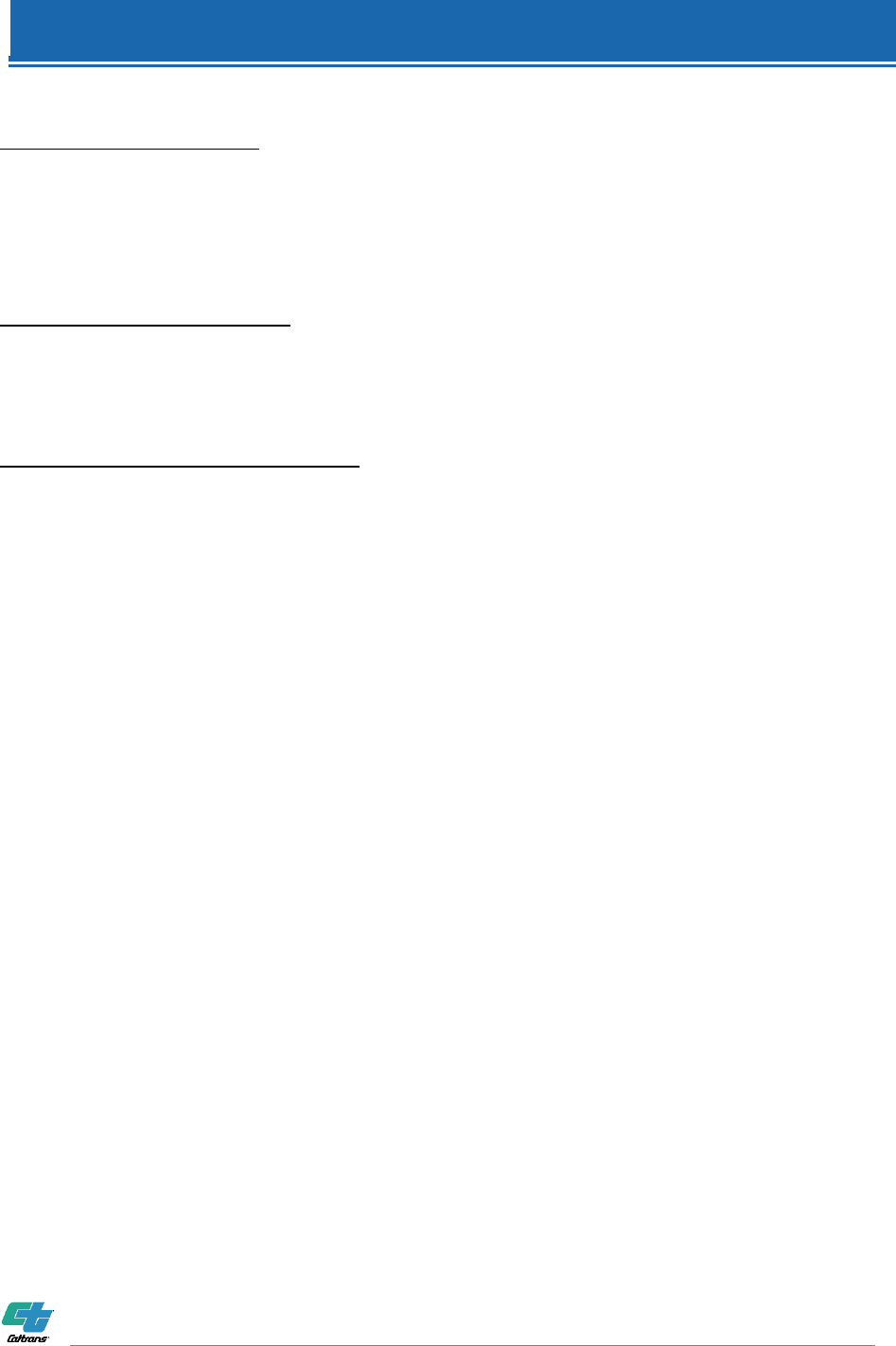

1.4.3.d Other Divisions

The Divisions of Maintenance and Design are available to support the resident engineer in

implementing the CQAP. Figure 1.4.1 reflects the many support services available to the

resident engineer.

Figure 1.4.1. Support Services Available to Resident Engineer

CONSTRUCTION QUALITY ASSURANCE PROGRAM MANUAL

Chapter 1—Construction Quality Assurance Program

California Department of Transportation • Division of Construction

Page 16 May 2023

Caltrans staff responsible for implementing the CQAP and for verifying that activities affecting

quality are properly performed have sufficient authority, access to work areas, and

organizational freedom to:

1. Identify quality problems.

2. Initiate, recommend, and provide solutions to quality problems through designated

channels.

3. Verify implementation of solutions.

4. Make sure that further processing, delivery, construction, and use are controlled until

proper resolution of a nonconformance, deficiency, or unsatisfactory condition has

occurred.

Responsible Caltrans staff have direct access to the management level at which appropriate

action can be taken, with sufficient independence from cost and schedule considerations

unduly influencing those decisions.

Table 1.4.1. lists supporting documentation.

Table 1.4.1. Organization Reference

Title

Chapter/Section

Description

Construction Manual

Chapter 1, Section 1

Construction Organization

Note: See Appendix A for the reference manuals

1.4.4 CQAP Process Evaluation

Evaluations are conducted routinely to determine the effectiveness of the various CQAP

processes. When deficiencies are found, corrective actions are taken by the appropriate

division. The following are examples of Caltrans’ annual CQAP process evaluations.

The Division of Construction compiles an annual Contract Administration Process Evaluation

(CAPE) report. Three to six elements of the contract administration process are evaluated for

strengths, weaknesses, recommendations for improvements, and district corrective action

plans. The CAPE is described in the Caltrans Division of Construction Charter: Contract

Administration Process Evaluation (CAPE). Refer to Appendix D.

The Office of Materials Management and Independent Assurance (OMMIA) performs annual

audits of each Office of Quality Assurance and Source Inspection (OQASI) Branch to make

sure that the branches are using consistent practices and procedures.

DES-SC management conducts an annual project record review for each structure

representative. If inadequacies are found, the reviewer conducts another review within 1

month to verify that the noted problems have been corrected.

Table 1.4.2. lists supporting documentation.

Table 1.4.2. Process Evaluation References

Title

Chapter/Section

Description

METS Quality Manual

Chapter 9

Quality Assurance and Source Inspection

(QASI) Branch Audits

BCRP, Vol. 1

Bridge Construction Memo E-2

Structural Construction Project Record

Review

Note: See Appendix A for the reference manuals

CONSTRUCTION QUALITY ASSURANCE PROGRAM MANUAL

Chapter 1—Construction Quality Assurance Program

California Department of Transportation • Division of Construction

May 2023 Page 17

1.5 Resource Management

The CQAP includes guidance for Caltrans to provide necessary resources to implement,

maintain, and continually improve the program’s effectiveness. Adequate personnel and

technological and environmental resources are provided to support project delivery in

conformance with regulatory requirements. These provisions are consistent with 23 CFR

637.205, “Policy,” requirements that adequate, qualified staff be maintained to administer the

CQAP. Caltrans also maintains the Transportation Laboratory, or Translab, a central

transportation laboratory in Sacramento, which is accredited by the American Association of

State Highway and Transportation Officials (AASHTO) Accreditation Program for the testing of

aggregate, asphalt binder, asphalt concrete, cement, concrete, and soils.

1.5.1 Competence, Awareness, and Training

The CQAP includes procedures to make sure the training of personnel performing activities

affecting quality and to confirm that suitable proficiency is achieved and maintained. Managers

of activities affecting quality are responsible for determining the personnel competencies

required and assessing needs; making sure that actions such as training are taken to satisfy

those needs; and evaluating the actions to confirm that personnel are adequately trained and

qualified to manage and perform assigned work activities.

Lists of available training courses and seminars are periodically provided to senior

management for distribution to managers who review the education and experience of

employees to determine whether additional training is required to perform specific tasks.

Managers are periodically requested to select personnel for scheduled safety training and

other employee development training, such as project management and field inspection.

Classes provided to the resident engineer or the structures representative are listed at the

following link:

https://construction.onramp.dot.ca.gov/division-construction-training-unit

Alternatively, contact the Division of Construction at: Construction.Publications@dot.ca.gov.

Table 1.5.1. lists supporting documentation:

Table 1.5.1. Training Policy Reference

Title

Chapter/Section

Description

Deputy Directive 75R1,

05/27/2015 (see Appendix C)

Training

Establishes policy for training

CONSTRUCTION QUALITY ASSURANCE PROGRAM MANUAL

Chapter 1—Construction Quality Assurance Program

California Department of Transportation • Division of Construction

Page 18 May 2023

1.6 Process Control

The CQAP includes process control procedures, based on specifications, drawings, process

parameters and approvals, and other appropriate methods, to control contractor construction

processes that affect material and work quality. Typical elements of construction process

control addressed throughout this manual include, but are not limited to:

• Approved material sources

• Work quality standards

• Quality control requirements

• Acceptance criteria

• Inspection and testing

1.6.1 Proposed Source of Materials

The contractor must notify the resident engineer of the sources of all materials obtained for

incorporation into the work. Such notification is required before the preconstruction

conference. The contractor must submit Form DOT CEM-3101, “Notice of Materials to Be

Used,” to list all materials to be used on the project.

1.6.1.a Material Identification and Traceability

The CQAP includes procedures to assure that contractors maintain identification, control, and

traceability of materials and components, from point of production through material

incorporation into the project. These procedures specify the methods and extent of material

identification and traceability to assure that only correct and acceptable items are incorporated

into the project. The procedures specify that item identification is maintained by heat number,

part number, serial number, or other appropriate means either on the item or on records

traceable to the item throughout fabrication, erection, delivery, installation, and use of the item.

The Standard Specifications specify the identification requirements for different materials. For

example, Section 49-2.02B(1)(d), “Markings,” requires the contractor to provide steel pipe

piling with markings showing the heat number. Commercial-quality items are not required to be

traceable.

The following methods are applicable:

• Contractor quality control plan. When applicable, the contractor is required to maintain the

traceability of materials.

• Certificate of compliance. These certificates are required to show a unique shipment

number or a serial number traceable to a specific silo, bin, lot, or heat number.

• Source inspection. Inspected materials meeting specifications are identified by lot

numbers. The METS inspector enters the lot number, a description, and the quantities of

materials inspected on Form TL-0029, “Report of Inspection of Material.”

Table 1.6.1. lists supporting documentation.

CONSTRUCTION QUALITY ASSURANCE PROGRAM MANUAL

Chapter 1—Construction Quality Assurance Program

California Department of Transportation • Division of Construction

May 2023 Page 19

Table 1.6.1. Control of Work and Materials References

Title

Chapter/Section

Description

Standard Specifications, 2022

6, 19, 20, 21, 37, 39, 40, 41, 47, 49,

50, 51, 52, 55, 57, 59, 74, 75, 80, 82,

84, 87

Quality Control, Materials

Construction Manual

Chapter 3, Section 5

Control of Work

Construction Manual

Chapter 3, Section 6

Control of Materials

Construction Manual

Chapter 6, Section 2

Acceptance of Manufactured or Fabricated

Materials and Products

BCRP Vol. 1

Section A, Memo A-1

Communicating Staff Responsibilities

QASI Manual

Section 5

Control of Work

QASI Manual

Section 6

Control of Materials

Note: See Appendix A for the reference manuals

1.6.1.b Handling, Storing, and Transporting

The CQAP includes guidance to assure the contractor’s control of handling, storage, shipping,

cleaning, and preservation of material and equipment to prevent damage or deterioration.

When necessary for special products, protective environments such as specific temperature

levels are required. Examples of materials requiring such measures include hot mix asphalt,

cement, asphalt emulsions, and prestressing steel. When no requirements are specified,

manufacturer’s requirements are followed.

Table 1.6.2. lists supporting documentation.

Table 1.6.2. Materials Handling Reference

Title

Chapter/Section

Description

QASI Manual

Section 50-B.03

In-process Inspection, Storage and

Packaging of Prestressing Strands

Note: See Appendix A for the reference manuals

1.6.1.c Control of Special Processes

A special process is any production process that generates outputs that cannot be measured,

monitored, or verified until after the resulting products have been used.

The CQAP includes procedures to confirm that special processes such as welding, non-

destructive testing, structural steel coating, and masonry construction are controlled and

performed by qualified personnel using procedures stated in applicable codes, standards,

specification criteria, and other special requirements. For example, Section 11, “Welding,” of

the Standard Specifications, states the personnel requirements and procedures required by

applicable codes.

Table 1.6.3. lists supporting documentation.

CONSTRUCTION QUALITY ASSURANCE PROGRAM MANUAL

Chapter 1—Construction Quality Assurance Program

California Department of Transportation • Division of Construction

Page 20 May 2023

Table 1.6.3. Special Processes References

Title

Chapter/Section

Description

Standard Specifications, 2022

Section 11

Welding

BCRP, Vol 2

Section 55

Steel Structures

BCRP, Vol 2

Section 11

Welding

QASI Manual

Section 1-A.06

Roles and Responsibilities of OQASI Branch

Staff

QASI Manual

Section 50

Prestressing Concrete

Note: See Appendix A for the reference manuals

CONSTRUCTION QUALITY ASSURANCE PROGRAM MANUAL

Chapter 1—Construction Quality Assurance Program

California Department of Transportation • Division of Construction

May 2023 Page 21

1.7 Inspection and Testing

The CQAP includes procedures for inspecting activities that affect quality to verify

conformance with the documented instructions, procedures, and drawings for accomplishing

the work. Examinations and measurements are required for each work operation to verify

quality. Procedures also specify that all required material or product testing is identified and

performed in accordance with written test procedures that incorporate the requirements and

acceptance limits in applicable construction documents.

1.7.1 Role of Resident Engineer

Inspection is an activity, using observation, measurement, testing, and judgment, that

compares one or more characteristics of a product with specified requirements to determine if

the product meets the requirements.

Caltrans resident engineers must review and monitor the technical inspection activities

performed by the contractor and Caltrans personnel to make sure: (1) necessary inspections

and testing are performed in a proper manner; (2) proper inspection techniques are used, and

(3) contract requirements for quality control and acceptance of material and work are enforced.

Procedures and guidelines prescribe source and field inspection activities that collectively

provide for the desired level of quality. Written inspection procedures provide guidance on: (1)

characteristics to be inspected; (2) inspection methods; (3) acceptance and rejection criteria,

and (4) methods for documenting inspection results.

Table 1.7.1. lists supporting documentation.

Table 1.7.1. Engineer Duties References

Title

Chapter/Section

Description

Construction Manual

Chapter 3, Section 5

Control of Work

Construction Manual

Chapter 4

Construction Details

QASI Manual

Section 1-A.06

Roles and Responsibilities of OQASI

Branch Staff

BCRP, Vol. 1

Section A, Memo A-1

Communicating Staff Responsibilities

Note: See Appendix A for the reference manuals

1.7.2 Quality Control Inspection and Testing

The quality control function is the responsibility of the contractor. The contractor is responsible

for establishing, implementing, and maintaining a quality control system to manage, control,

document, and make sure that all work complies with the requirements of the plans and

specifications. The quality control system must assure the adequate control and quality for

materials, equipment, work, fabrication, and construction by the contractor and its

subcontractors, suppliers, authorized laboratories, and consultants.

The purpose of quality control activities is to measure the quality characteristics and inspect

the activities that affect production when corrective action can be taken to prevent

nonconforming material from being incorporated into the project. Effective quality control tests

allow results to be obtained during the process to allow adjustments to meet acceptance

criteria.

Caltrans may use results from contractor quality control testing for acceptance. For

acceptance of results, the following Caltrans activities must occur:

1. Authorization of the contractor’s quality control plan

CONSTRUCTION QUALITY ASSURANCE PROGRAM MANUAL

Chapter 1—Construction Quality Assurance Program

California Department of Transportation • Division of Construction

Page 22 May 2023

2. Accreditation of the contractor’s laboratory

3. Authorization of qualifications of contractor’s testing personnel

4. Evaluation of quality control sampling and testing

5. Verification that validates the quality of sampling and testing

Details for the production and placement of hot mix asphalt for projects under the statistical

pay factor specification are provided in the Caltrans Division of Construction Quality Control

Manual for Hot Mix Asphalt Using Statistical Pay Factors.