ESRD Surveyor Training

Interpretive Guidance

Final Version 1.1

October 3, 2008

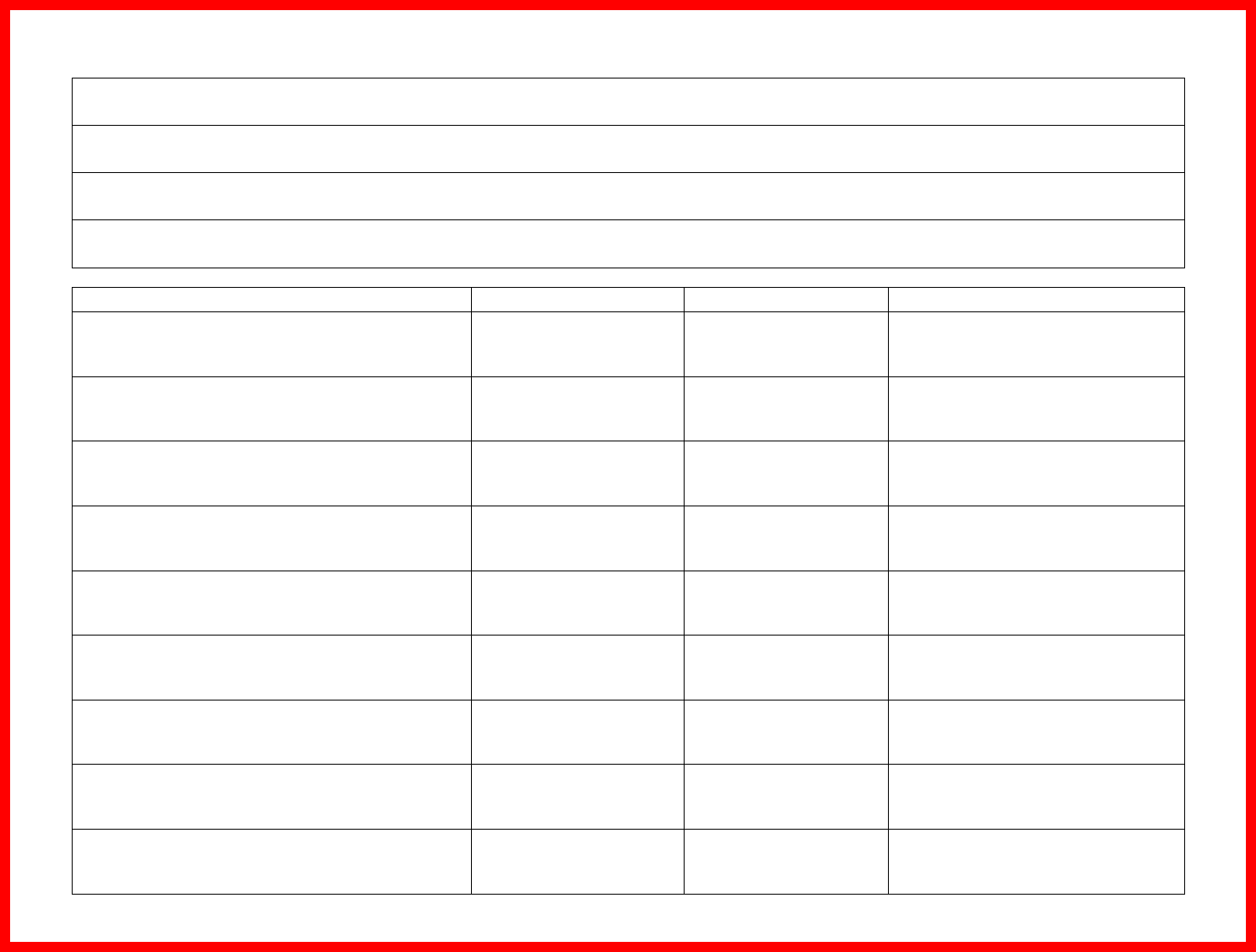

If found, return this manual to:

Name:

Address:

City: State: Zip:

Phone: ( ) Fax: ( ) Email:

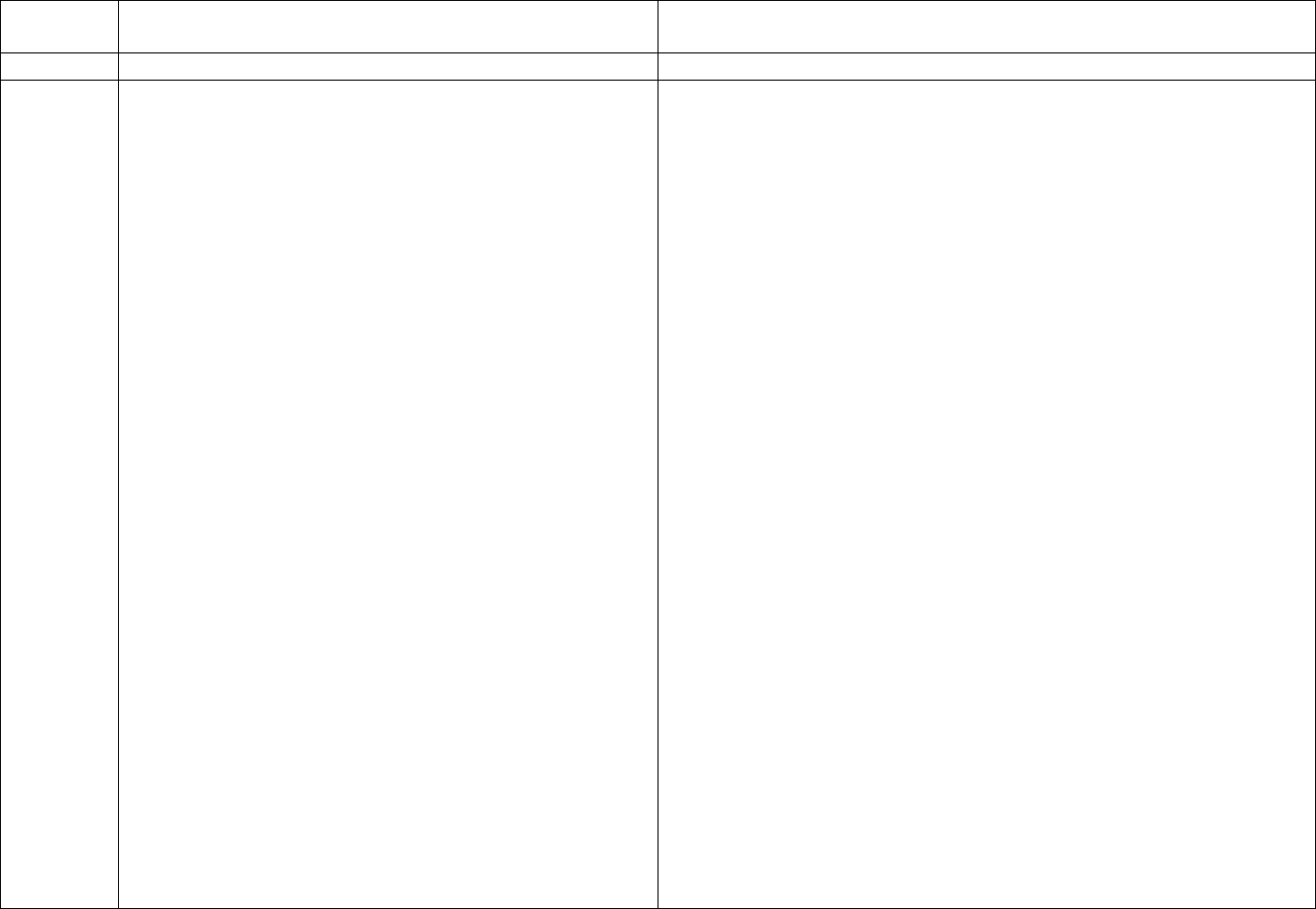

Helpful Contact Name

Phone Number(s)

Fax Number(s)

Email Address(es)

Regional Office:

ESRD Network:

State Headquarters:

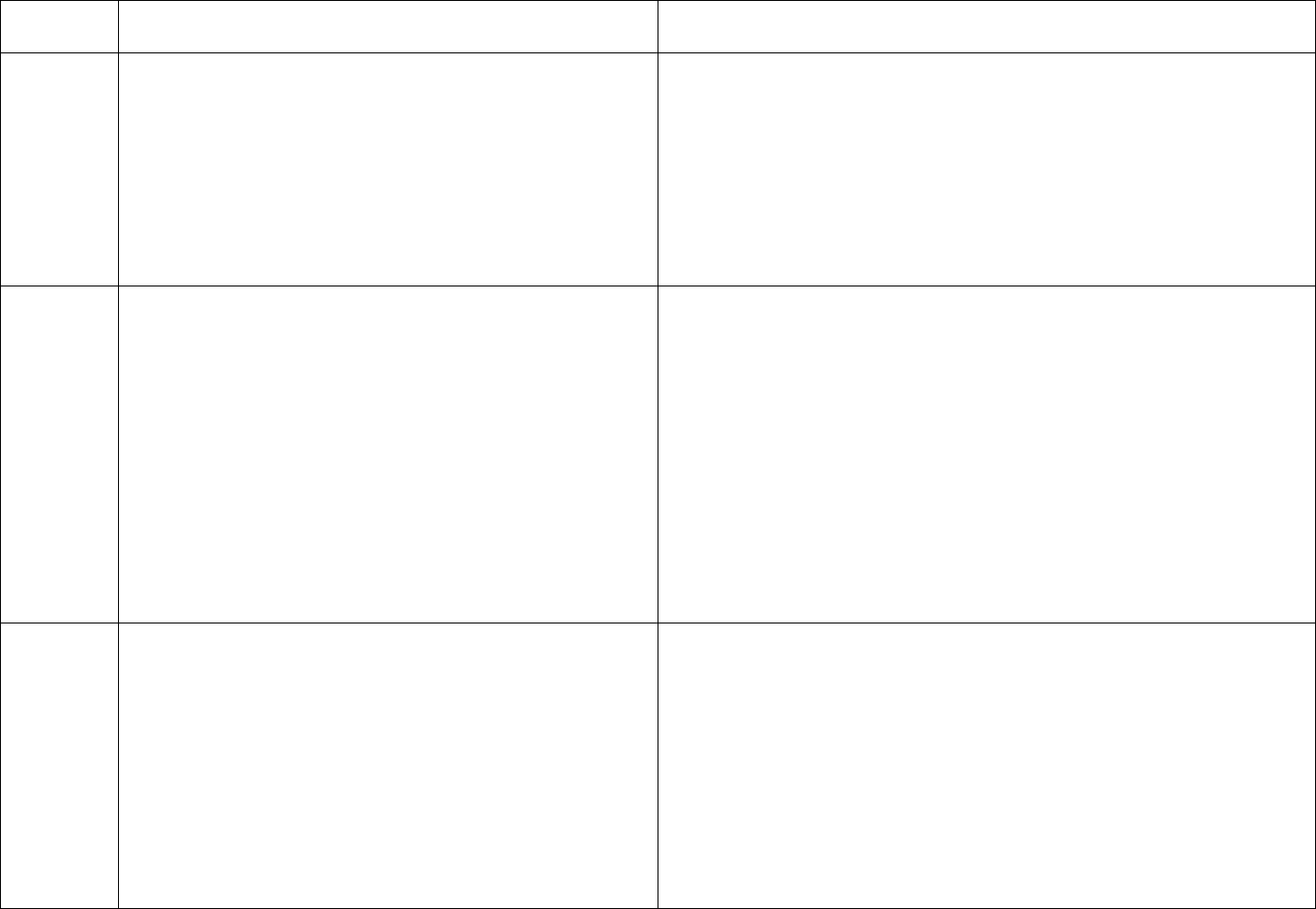

Revision History

Revision Effective Date Author Description of Change

1.1 05/07/2014 Helen Blakey This document had internal changes previously recorded by the ESRD team which

are identified with this version number. This table is for the purpose of recording

future changes.

This version is being released for the class offering beginning June 23, 2014.

iii

iv

PART 494 CONDITIONS FOR COVERAGE FOR END-STAGE RENAL DISEASE FACILITIES

Interpretive Guidance

Subpart A—General Provisions ..................................................................................................................................................................................... 1

§ 494.1 Basis and scope. ............................................................................................................................................................................................. 1

§ 494.10 Definitions. .................................................................................................................................................................................................. 2

§ 494.20 Condition: Compliance with Federal, State, and local laws and regulations. ............................................................................................. 3

Subpart B—Patient Safety .............................................................................................................................................................................................. 4

§ 494.30 Condition: Infection control. ....................................................................................................................................................................... 4

§ 494.40 Condition: Water and dialysate quality. .................................................................................................................................................... 33

§ 494.50 Condition: Reuse of hemodialyzers and bloodlines. ............................................................................................................................... 116

§ 494.60 Condition: Physical environment. ........................................................................................................................................................... 162

Subpart C—Patient Care ............................................................................................................................................................................................ 175

§ 494.70 Condition: Patients’ rights. ...................................................................................................................................................................... 175

§ 494.80 Condition: Patient assessment. ................................................................................................................................................................ 186

§ 494.90 Condition: Patient plan of care. ............................................................................................................................................................... 202

§ 494.100 Condition: Care at home. ....................................................................................................................................................................... 223

§ 494.110 Condition: Quality assessment and performance improvement. ........................................................................................................... 246

§ 494.120 Condition: Special purpose renal dialysis facilities. .............................................................................................................................. 260

§ 494.130 Condition: Laboratory services. ............................................................................................................................................................ 265

Subpart D – Administration ........................................................................................................................................................................................ 266

§ 494.140 Condition: Personnel qualifications. ..................................................................................................................................................... 266

§ 494.150 Condition: Responsibilities of the medical director. ............................................................................................................................. 276

§ 494.160 [Reserved]

§ 494.170 Condition: Medical records. .................................................................................................................................................................. 281

§ 494.180 Condition: Governance. ......................................................................................................................................................................... 286

TAG

NUMBER

REGULATION

INTERPRETIVE GUIDANCE

Subpart A—General Provisions

§ 494.1 Basis and scope.

(a) Statutory basis. This part is based on the following

provisions:

(1) Section 299I of the Social Security Amendments of

1972 (Pub. L. 92-603), which extended Medicare

coverage to insured individuals, their spouses, and their

dependent children with ESRD who require dialysis or

transplantation.

(2) Section 1861(e)(9) of the Act, which requires

hospitals to meet such other requirements as the

Secretary finds necessary in the interest of health and

safety of individuals who are furnished services in the

institution.

(3) Section 1861(s)(2)(F) of the Act, which describes

“medical and other health services” covered under

Medicare to include home dialysis supplies and

equipment, self-care home dialysis support services, and

institutional dialysis services and supplies.

(4) Section 1862(a) of the Act, which specifies

exclusions from coverage.

(5) Section 1881 of the Act, which authorizes Medicare

coverage and payment for the treatment of ESRD in

approved facilities, including institutional dialysis

services, transplantation services, self-care home dialysis

services, and the administration of erythropoiesis-

stimulating agent(s).

(6) Section 12(d) of the National Technology Transfer

and Advancement Act of 1995 (Pub. L. 104-113), which

requires Federal agencies to use technical standards that

are developed or adopted by voluntary consensus

standards bodies, unless their use would be inconsistent

with applicable law or otherwise impractical.

Final Version 1.1 Page 1 of 299

TAG

NUMBER

REGULATION

INTERPRETIVE GUIDANCE

(b) Scope. The provisions of this part establish the

conditions for coverage of services under Medicare and

are the basis for survey activities for the purpose of

determining whether an ESRD facility’s services may be

covered.

§ 494.10 Definitions

.

As used in this part–

Dialysis facility means an entity that provides outpatient

maintenance dialysis services, or home dialysis training

and support services, or both. A dialysis facility may be

an independent or hospital-based unit (as described in

413.174(b) and (c) of this chapter) that includes a self-

care dialysis unit that furnishes only self-dialysis

services.

Discharge means the termination of patient care services

by a dialysis facility or the patient voluntarily

terminating dialysis when he or she no longer wants to

be dialyzed by that facility.

Furnishes directly means the ESRD facility provides the

service through its own staff and employees or through

individuals who are under direct contract to furnish these

services personally for the facility.

Home dialysis means dialysis performed at home by an

ESRD patient or caregiver who has completed an

appropriate course of training as described in §

494.100(a) of this part.

Final Version 1.1 Page 2 of 299

TAG

NUMBER

REGULATION

INTERPRETIVE GUIDANCE

Self-dialysis means dialysis performed with little or no

professional assistance by an ESRD patient or caregiver

who has completed an appropriate course of training as

specified in § 494.100(a) of this part.

Transfer means a temporary or permanent move of a

patient from one dialysis facility to another that requires

a transmission of the patient’s medical record to the

facility receiving the patient.

V100

§ 494.20 Condition: Compliance with Federal, State,

and local laws and regulations.

This Condition emphasizes Centers for Medicare & Medicaid

Services’ (CMS) role as a partner with State and local governments

and with other Federal agencies. The purpose of this Condition is to

affirm the principle that Medicare reimbursement should be

distributed to ESRD facilities that comply with local, State and

Federal laws and rules. This Condition is not intended to adjudicate

laws and rules from state and local governmental agencies. This

Condition should only be cited when a specific “deficient” practice

has been completely settled with the appropriate entity, and a final

decision of non-compliance with the other entity’s requirement has

been reached. Facilities are expected to comply fully with

investigations conducted by public health, regulatory, or law

enforcement authorities.

V101

The facility and its staff must operate and furnish

services in compliance with applicable Federal, State,

and local laws and regulations pertaining to licensure and

any other relevant health and safety requirements.

Applicable laws and regulations of other Federal agencies which

could be cited here include the Department of Health & Human

Services’ Office of Civil Rights (DHHS OCR) for the privacy

provisions of the Health Insurance Portability and Accountability Act

(HIPAA), the Department of Justice Civil Rights Division for Title III

related to public accommodations under the Americans with

Disabilities Act (ADA); the Occupational Safety and Health

Administration (OSHA) for regulations related to employee safety;

and the Food and Drug Administration (FDA) for regulations related

to the safety of drugs and medical devices. If a drug or device may

have caused or contributed to a serious injury or illness, the facility

Final Version 1.1 Page 3 of 299

TAG

NUMBER

REGULATION

INTERPRETIVE GUIDANCE

must notify the manufacturer and the FDA using FDA’s User Facility

reporting requirements. Clusters of adverse events (infectious or non-

infectious) should also be reported to the appropriate State or local

public health department, as required by those authorities. Because

these other Federal laws are complex, surveyors are not expected to be

their enforcement mechanism. If noncompliance with the laws or rules

of another Federal agency is suspected or noted, contact your CMS

Regional Office (RO) for guidance.

Compliance with reporting communicable diseases is addressed in the

Condition for Infection control at V145. Compliance with

requirements for FDA reporting related to dialyzer/bloodline reuse is

addressed in the Condition for Reuse at V383. Compliance with

licensure and certification of facility staff is addressed in the

Condition for Personnel qualifications at V681.

Subpart B—Patient Safety

V110

§ 494.30 Condition: Infection control.

This Condition incorporates as regulation two documents from the

Centers for Disease Control and Prevention (CDC) and also includes

CMS-developed regulations. These infection control requirements

apply to both the chronic dialysis in-center facility and any home

dialysis program(s).

Survey of this Condition requires observations of care delivery,

interviews with staff and patients, and review of medical records,

facility logs, policies and procedures and quality assessment and

performance improvement (QAPI) documentation. Direct care staff

are observed and interviewed relative to infection control practices.

Administrative and supervisory staff, as well as the medical director,

may be interviewed to clarify issues. Medical and administrative

records must demonstrate recognition of any potential infection and

actions taken to decrease the transmission of infection within the

dialysis facility.

Final Version 1.1 Page 4 of 299

TAG

NUMBER

REGULATION

INTERPRETIVE GUIDANCE

If deficient practices noted in infection control techniques are

multiple, pervasive, or of an extent to present a risk to patient health

and safety, Condition level non-compliance should be considered.

V111

The dialysis facility must provide and monitor a sanitary

environment to minimize the transmission of infectious

agents within and between the unit and any adjacent

hospital or other public areas.

The CDC defines a “sanitary environment” as an environment that

meets the “Standard Precautions” for an inpatient hospital setting plus

the more stringent precautions which are recommended for

hemodialysis units because of the increased potential for

contamination with blood and pathogenic microorganisms.

“Standard Precautions” apply to the care of all patients in any

healthcare setting and include the use of gloves, gown, or mask

whenever needed to prevent contact of the health-care worker with

blood, secretions, excretions, or contaminated items.

Standard Precautions are the CDC’s system of infection control

precautions for all health care settings. Standard Precautions emerged

from Universal Precautions and (UP) and Body Substance Isolation

(BSI) and are based on the principle that all blood, body fluids,

secretions, and excretions (except sweat), non-intact skin, and mucous

membranes may contain transmissible infectious agents.

Dialysis facilities should adhere to Standard Precautions for all health

care settings and the additional precautions recommended for

hemodialysis facilities for infection control. Infection control

requirements apply to both the chronic dialysis in-center facility and

any home dialysis program(s).

V112

(a) Standard: Procedures for infection control. The

facility must demonstrate that it follows standard

infection control precautions by implementing—

(1)(i) The recommendations (with the exception of

screening for hepatitis C), found in “Recommendations

for Preventing Transmission of Infections Among

Chronic Hemodialysis Patients,” developed by the

The CDC “Recommendations for Preventing Transmission of

Infections Among Chronic Hemodialysis Patients” (MMWR, Vol.

50/No. RR-5), pages 18 to 28, including the “Recommended Infection

Control Practices for Hemodialysis Units at a Glance,” is incorporated

by reference and has the authority of regulation. For purposes of these

Conditions for Coverage, the portions of the CDC infection control

recommendations which are incorporated by reference are mandatory

Final Version 1.1 Page 5 of 299

TAG

NUMBER

REGULATION

INTERPRETIVE GUIDANCE

Centers for Disease Control and Prevention, Morbidity

and Mortality Weekly Report, volume 50, number RR05,

April 27, 2001, pages 18 to 28. The Director of the

Federal Register approves this incorporation by reference

in accordance with 5 U.S.C. 552(a) and 1 CFR Part 51.

This publication is available for inspection at the CMS

Information Resource Center, 7500 Security Boulevard,

Central Building, Baltimore, MD or at the National

Archives and Records Administration (NARA). Copies

may be obtained at the CMS Information Resource

Center. For information on the availability of this

material at NARA, call 202–741–6030, or go to:

http://www.archives.gov/federal_register/code_of_regula

tions/ibr_locations.html. The recommendation found

under section header “HBV-Infected Patients”, found on

pages 27 and 28 of RR05 (“Recommendations for

Preventing Transmission of Infections Among Chronic

Hemodialysis Patients”), concerning isolation rooms,

must be complied with by February 9, 2009.

and must be adhered to and demonstrated within the dialysis facility.

When serving as Regulation text, the words of the CDC document are

excerpted exactly as written. When serving as a part of the

Interpretive Guidance, the language incorporated from these

documents has been edited for clarity, brevity, and to eliminate

redundant requirements. The entire CDC document includes

background information and rationale for the CDC recommended

practices and can be used as an informational resource.

According to the CDC, “preventing transmission among chronic

hemodialysis patients of bloodborne viruses and pathogenic bacteria

from both recognized and unrecognized sources of infection requires

implementation of a comprehensive infection control program. The

components of such a program include infection control practices

specifically designed for the hemodialysis setting, including routine

serologic testing and immunization, surveillance, training and

education.”

CDC’s components of a comprehensive infection control program to

prevent transmission of infections among chronic hemodialysis

patients include:

• Infection control practices for hemodialysis units

- Infection control precautions specifically designed to prevent

transmission of bloodborne viruses and pathogenic bacteria

among patients.

- Routine serologic testing for hepatitis B virus infections.

- Vaccination of susceptible patients against hepatitis B.

- Isolation of patients who test positive for hepatitis B surface

antigen.

• Surveillance for infections and other adverse events.

• Infection control training and education.

The infection control practices recommended by CDC for

Final Version 1.1 Page 6 of 299

TAG

NUMBER

REGULATION

INTERPRETIVE GUIDANCE

hemodialysis units will reduce opportunities for patient-to-patient

transmission of infectious agents, directly or indirectly through

contaminated devices, equipment and supplies, environmental

surfaces, or hands of personnel. These practices should be carried out

routinely for all patients in the chronic hemodialysis setting because

of the increased potential for blood contamination during

hemodialysis and because many patients are colonized or infected

with pathogenic bacteria. Those infection control practices include

additional measures to prevent Hepatitis B Virus (HBV) transmission

because of the high titer of HBV in each milliliter of infected blood

and its ability to survive on environmental surfaces.

According to the CDC, for patients at increased risk for transmission

of pathogenic bacteria, including antimicrobial-resistant strains,

additional precautions might also be necessary. Patients with either an

infected skin wound with drainage uncontrolled by dressings or

uncontrolled fecal incontinence or diarrhea should be dialyzed at a

station with as few adjacent stations as possible. Staff members

treating the patient should wear a separate gown for the care of the

patient, and supplies and equipment (such as blood pressure cuffs)

should not be shared between patients who have uncontrolled draining

wounds.

Surveillance for infections and other adverse events is required to

monitor the effectiveness of infection control practices, as well as

training and education of both staff members and patients to ensure

that appropriate infection control behaviors and techniques are carried

out.

V113

CDC RR-5 as Adopted by Reference 42 CFR 494.30

(a)(1)(i)

Wear disposable gloves when caring for the patient or

touching the patient’s equipment at the dialysis station.

Staff must remove gloves and wash hands between each

According to the CDC, handwashing is the most important measure to

prevent contaminant transmission.

Because exposure to blood and potentially contaminated items can be

routinely anticipated during hemodialysis, gloves are required

Final Version 1.1 Page 7 of 299

TAG

NUMBER

REGULATION

INTERPRETIVE GUIDANCE

patient or station.

whenever caring for a patient or touching the patient’s equipment. To

facilitate glove use, a supply of clean nonsterile gloves and waste

receptacles should be readily accessible to each dialysis station and

work area. Gloves should be changed frequently during patient care.

Examples of when gloves should be worn:

• Staff members should wear gloves while performing procedures

which have the potential for exposure to blood, dialysate and other

potentially infectious substances. This includes procedures such as

caring for patients' vascular accesses or catheters, setting up

reprocessed dialyzers pre dialysis treatment, inserting or removing

the vascular access needles, connecting the dialysis blood lines to

the vascular access needle lines or catheter lines, touching the

dialysis blood lines, dialyzer, or machine during or after a dialysis

treatment, administering intravenous medications, handling blood

lines, dialyzers, dialysate tubing and machines post dialysis

treatment, and cleaning and disinfecting the dialysis machine and

chair post dialysis treatment.

• Gloves must be provided to patients and visitors if these

individuals assist with procedures which risk exposure to blood or

body fluids, such as when self-cannulating or holding access sites

post treatment to achieve hemostasis.

• Chair-side computer keyboards/screens can easily become

contaminated because of their proximity to the patient station.

Hand hygiene is imperative after contact with the chair-side

computer and before contact with the patient, regardless of

whether contact with the computer occurred through gloved or

ungloved hands.

Examples of when gloves should be changed:

• When soiled (e.g., with blood, dialysate or other body fluids);

• When going from a “dirty” area or task to a “clean” area or task.

Final Version 1.1 Page 8 of 299

TAG

NUMBER

REGULATION

INTERPRETIVE GUIDANCE

The CDC defines a “dirty” area as an area where there is a

potential for contamination with blood or body fluids and areas

where contaminated or “used” supplies, equipment, blood supplies

or biohazard containers are stored or handled. A “clean” area is an

area designated only for clean and unused equipment and supplies

and medications;

• When moving from a contaminated body site to a clean body site

of the same patient; and

• After touching one patient or their machine and before arriving to

care for another patient or touch another patient’s machine.

In addition, a new pair of clean gloves must be used each time for

access site care, vascular access cannulation, administration of

parenteral medications or to perform invasive procedures. The

intention is to ensure that clean gloves which have not previously

touched potentially contaminated surfaces are in use whenever there is

a risk for cross contamination to a patient’s blood stream to occur.

“Hand hygiene” includes either washing hands with soap and water,

or using a waterless alcohol-based antiseptic hand rub with 60-90%

alcohol content. Hands should be washed with soap and water if

visibly soiled. If not visibly soiled, hand hygiene with alcohol-based

hand rub may be used. The CDC recommends that hand washing

incorporate rubbing hands together “vigorously” for 15 seconds, and

that the use of alcohol-based rubs incorporate covering all surfaces of

hands and fingers, until hands are dry. According to the CDC, even

with glove use, hand hygiene is necessary after glove removal because

hands can become contaminated through small defects in gloves and

from the outer surface of gloves during glove removal.

Examples of when hand hygiene should be performed:

• After touching blood, body fluids, secretions, excretions, and

potentially contaminated items;

Final Version 1.1 Page 9 of 299

TAG

NUMBER

REGULATION

INTERPRETIVE GUIDANCE

• Before and after direct contact with patients;

• Before performing any invasive procedure such as vascular access

cannulation or administration of parenteral medications;

• Immediately after gloves are removed;

• After contact with inanimate objects, including medical equipment

or environmental surfaces at the patient station;

• Before entering and on exiting the patient treatment areas; and

• When moving from a contaminated body site to a clean body site

of the same patient.

The CDC document, “Prevention of Intravascular Catheter-Related

Infections,” (“RR-10” which is adopted as regulation in this section),

states that staff should wear clean or sterile gloves when changing the

dressing on intravascular catheters. Staff must observe hand hygiene

before and after palpating catheter insertion sites, as well as before

and after accessing or dressing an intravascular catheter.

Hand hygiene is required after every direct contact with a patient and

between patient contacts, even if the contact is casual. Gloves are not

necessary for casual social contact with a patient, for example, staff

members may touch the patient’s shoulder, take his/her arm, or shake

hands without wearing gloves. However, gloves should always be

worn anytime contact with blood or body fluids is anticipated.

Physicians and non-physician practitioners functioning in lieu of

physicians (i.e., advanced practice registered nurses and physician

assistants), social workers and dietitians must follow these same

requirements for glove use and hand hygiene.

V114

CDC RR-5 as Adopted by Reference 42 CFR 494.30

(a)(1)(i)

A sufficient number of sinks with warm water and soap

A “sufficient number” means that sinks are easily accessible and

readily available in the patient treatment area and in other appropriate

areas such as the reuse room, medication area, home training room,

and isolation area/room to meet the needs of the staff and patients.

Final Version 1.1 Page 10 of 299

TAG

NUMBER

REGULATION

INTERPRETIVE GUIDANCE

should be available to facilitate hand washing.

Sinks must be plumbed with both hot and cold water; if the flow of

water is started through motion detection, adjustments to the system

must assure that warm water is available to encourage staff to wash

their hands according to CDC recommendations (see V113).

Handwashing sinks should be dedicated only for handwashing

purposes and should remain clean. Avoid placing, cleaning, or

draining used items in handwashing sinks. Used or contaminated

items should be handled in designated utility sinks. The facility should

have a sink available for patients to wash their access sites prior to

treatment and their hands after treatment. This sink may also be used

by staff for handwashing. Soap and a supply of paper towels protected

from contamination must be available at each sink.

V115

CDC RR-5 as Adopted by Reference 42 CFR 494.30

(a)(1)(i)

Staff members should wear gowns, face shields, eye

wear, or masks to protect themselves and prevent soiling

of clothing when performing procedures during which

spurting or spattering of blood might occur (e.g., during

initiation and termination of dialysis, cleaning of

dialyzers, and centrifugation of blood). Staff members

should not eat, drink, or smoke in the dialysis treatment

area or in the laboratory.

Staff should wear personal protective equipment (PPE) appropriate to

the anticipated potential exposure. Staff should wear PPE during the

initiation and termination of dialysis treatment, manipulation of access

needles or catheters, administration of medications through the

extracorporeal circuit or by subcutaneous injection, the reprocessing

of dialyzers, and cleaning and disinfecting of patient care supplies and

equipment. Protective clothing or gear must be changed if it becomes

soiled with blood, body fluids (including dialysate), secretions, or

excretions.

Street clothes, scrub suits, or uniforms are sufficient attire within the

dialysis unit, except for times when the spurting or spattering of

blood, body fluids, potentially-contaminated substances, or chemicals

might occur. At those times a cover garment which provides an

impervious barrier to fluids must be worn. This could be a lab coat, a

gown, or an apron which incorporates sleeves. The garment may open

to the back or front, but must be closed in front during use for patient

care. The protective garment should fully cover the arms and torso

from the neck area to the thigh/knee area. Aprons without sleeves are

not sufficient PPE for procedures which may result in spurting or

Final Version 1.1 Page 11 of 299

TAG

NUMBER

REGULATION

INTERPRETIVE GUIDANCE

spattering of blood.

Physicians, advanced practice registered nurses, physician assistants,

social workers and dietitians must wear a cover garment which

provides an impervious barrier to fluids if they are providing service

to any patient in the treatment area during a time of high risk for

spurting or spattering of blood, as, for example, during initiation or

termination of dialysis. The garment should be changed if it becomes

soiled. Visitors must be provided impervious cover garments if they

are in the treatment area during initiation or termination of dialysis.

Home patients do not have to wear gowns when they are caring for

themselves. The partner or caregiver of a home patient should wear

appropriate PPE, including gloves, and practice appropriate hand

hygiene.

Separate PPE (gown, face shield, etc.) should be used in the isolation

area/room and removed before leaving the isolation area/room. If a

patient’s family member or other visitors are allowed in the isolation

area, staff should provide these individuals barrier PPE, to be worn

during the visit and removed when leaving.

The “treatment area” includes the reuse room and home training area.

Staff must avoid any other activity which would allow self-

contamination, such as applying lip balm or handling/inserting contact

lenses in the treatment area. Patients may eat and drink at their

dialysis stations, depending on facility policies. If non-disposable

dishes are provided by the facility, they should be cleaned in the usual

manner; no special care of these items is needed.

V116

CDC RR-5 as Adopted by Reference 42 CFR 494.30

(a)(1)(i)

Items taken into the dialysis station should either be

According to the CDC, any item taken to a patient’s dialysis station

could become contaminated with blood and other body fluids and

serve as a vehicle of transmission to other patients either directly or by

contamination from the hands of personnel. Items taken to a patient’s

Final Version 1.1 Page 12 of 299

TAG

NUMBER

REGULATION

INTERPRETIVE GUIDANCE

disposed of, dedicated for use only on a single patient, or

cleaned and disinfected before being taken to a common

clean area or used on another patient.

-- Nondisposable items that cannot be cleaned and

disinfected (e.g., adhesive tape, cloth covered blood

pressure cuffs) should be dedicated for use only on a

single patient.

-- Unused medications (including multiple dose vials

containing diluents) or supplies (syringes, alcohol swabs,

etc.) taken to the patient’s station should be used only for

that patient and should not be returned to a common

clean area or used on other patients.

dialysis station include those items placed on the top or sides (in

baskets) of dialysis machines and on dialysis chairs.

After use, all equipment and supplies must be considered as

potentially blood contaminated, and should be separated, handled with

caution, and either disinfected or discarded. If provided, linens should

be removed after use, separated from clean items and laundered. If

blood pressure cuffs are used for multiple patients, the coverings must

be disposable or able to be adequately disinfected.

If the facility provides linens or blankets for patient use, these items

should be considered as potentially contaminated with blood. If

patients bring their own blankets, pillows, etc. patients should be

instructed about washing the linen they bring to treatment and using

bleach to remove blood stains.

If the facility provides portable or cellular phones, remote controls, or

individual televisions for patient use during treatment, these need to

be cleaned if shared among patients.

V117

CDC RR-5 as Adopted by Reference 42 CFR 494.30

(a)(1)(i)

Clean areas should be clearly designated for the

preparation, handling and storage of medications and

unused supplies and equipment. Clean areas should be

clearly separated from contaminated areas where used

supplies and equipment are handled. Do not handle and

store medications or clean supplies in the same or an

adjacent area to that where used equipment or blood

samples are handled.

When multiple dose medication vials are used (including

vials containing diluents), prepare individual patient

According to the CDC, measures to prevent contamination of clean or

sterile items include a) preparing medications in a clean room or area

separated or away from the patient treatment area and designated only

for medications; b) not handling, cleaning, or storing potentially

contaminated (i.e., used) supplies, equipment, blood samples, or

biohazard containers in areas where medications and clean (i.e.,

unused) equipment and supplies are handled; and c) delivering

medications separately to each patient: common medication carts must

not be used to deliver medications.

It is acceptable for the medication prep area to be within the treatment

area, but the space should be away from individual patient stations

and a clean area must be provided. Medications used in the home

training area may be prepared in the same room where home training

Final Version 1.1 Page 13 of 299

TAG

NUMBER

REGULATION

INTERPRETIVE GUIDANCE

doses in a clean (centralized) area away from dialysis

stations and deliver separately to each patient. Do not

carry multiple dose medication vials from station to

station.

Do not use common medication carts to deliver

medications to patients. If trays are used to deliver

medications to individual patients, they must be cleaned

between patients.

is conducted; a clean area should be provided for this activity.

The patient treatment area should have designated "clean" and "dirty"

areas. The CDC defines a “dirty” area as an area where there is a

potential for contamination with blood or body fluids and areas where

contaminated or “used” supplies, equipment, blood supplies or

biohazard containers are stored or handled. A “clean” area is an area

designated only for clean and unused equipment and supplies and

medications. Staff must remain aware of the separation of clean and

dirty areas to prevent cross-contamination.

Recognize that smaller, older facilities may face challenges in

achieving separate areas for clean and dirty equipment or tasks; the

key is protection of clean areas and items from cross contamination.

V118

CDC RR-5 as Adopted by Reference 42 CFR 494.30

(a)(1)(i)

Intravenous medication vials labeled for single use,

including erythropoietin, should not be punctured more

than once.

According to the CDC, once a needle has entered a vial labeled for

single use, the sterility of the product can no longer be guaranteed.

Residual medication from two or more vials should not be pooled into

a single vial.

Single use vials/ampules must be used for only one patient, should not

be entered more than once, and if entered, may not be stored for future

use.

Staff should only enter vials with a new sterile syringe and needle. If

both vials are single use and are discarded after the single entry into

each, the same syringe may be used. If either vial is multi-use, a

different syringe must be used for entry into each vial.

V119

CDC RR-5 as Adopted by Reference 42 CFR 494.30

(a)(1)(i)

If a common supply cart is used to store clean supplies in

the patient treatment area, this cart should remain in a

designated area at a sufficient distance from patient

According to the CDC, if a common supply cart is used, it must be

kept in a designated area away from any areas where the spurting or

spattering of blood or fluid may occur, and the cart should not travel

between stations.

Medication vials, patient care items including gloves, or other dialysis

Final Version 1.1 Page 14 of 299

TAG

NUMBER

REGULATION

INTERPRETIVE GUIDANCE

stations to avoid contamination with blood. Such carts

should not be moved between stations to distribute

supplies.

Do not carry medication vials, syringes, alcohol swabs or

supplies in pockets.

supplies should not be in pockets, inside fanny packs, etc.

Supplies of gloves should be strategically placed so that staff has

adequate access for both routine and emergency use.

V120

CDC RR-5 as Adopted by Reference 42 CFR 494.30

(a)(1)(i)

Use external venous and arterial pressure transducer

filters/protectors for each patient treatment to prevent

blood contamination of the dialysis machines’ pressure

monitors.

If the external transducer protector becomes wet, replace

immediately and inspect the protector. If fluid is visible

on the side of the transducer protector that faces the

machine, have qualified personnel open the machine

after the treatment is completed and check for

contamination. This includes inspection for possible

blood contamination of the internal pressure tubing set

and pressure sensing port. If contamination has occurred,

the machine must be taken out of service and disinfected

using either 1:100 dilution of bleach (300–600 mg/L free

chlorine) or a commercially available, EPA-registered

tuberculocidal germicide before reuse.

Change filters/protectors between each patient treatment,

and do not reuse them. Internal transducer filters do not

need to be changed routinely between patients.

Recognize that some bloodlines do not have external transducer

protectors; this requirement would not apply in those cases, except for

changing the bloodlines between patients.

According to the CDC, external transducer protectors, [which provide

a protective barrier between dialysis bloodlines and the dialysis

machine], should not be reused. “Wet” (“wet with blood or other

fluid”) external transducer protectors must be changed immediately

and the side of the external transducer protector that faces the machine

should be inspected for visible fluid. If the external transducers are

wetted with blood, the staff should inspect the wetted transducer to

see if fluid has passed through. If fluid or blood is visible on the side

of the transducer protector that faces the machine, the machine must

be opened by qualified personnel after the dialysis treatment to allow

the internal transducer to be inspected for contamination, including

inspection for possible blood contamination of the internal pressure

tubing set and pressure sensing port. Frequent blood line pressure

alarms or frequent requirements for adjustment of the blood level in

the drip chamber can be indicators of contamination of the internal

transducer filter.

V121

(4) And maintaining procedures, in accordance with

applicable State and local laws and accepted public

health procedures, for the—

Potentially-infectious waste and soiled laundry should be removed

from the patient treatment area throughout the day as the containers

are filled in order to maintain an environment that enhances safe

Final Version 1.1 Page 15 of 299

TAG

NUMBER

REGULATION

INTERPRETIVE GUIDANCE

(i) Handling, storage and disposal of potentially

infectious waste; and

patient care. All disposable items should be placed in bags thick

enough to prevent leakage.

Any wastes contaminated with blood should be considered

“infectious” and handled according to local, State, and Federal

regulations governing medical waste disposal.

Biohazardous waste containers should be clearly labeled and sealed

prior to being full. Biohazardous waste should be stored in an area

that is protected from casual access and from the ability to

contaminate the water supply.

V122

(ii) Cleaning and disinfection of contaminated surfaces,

medical devices, and equipment.

A facility should establish written protocols for cleaning and

disinfecting surfaces and equipment, including careful mechanical

cleaning before any disinfection process. Refer to CDC RR 5 Table 2

included below for guidance.

Any manufacturer’s guidance for sterilization or disinfection of an

item should be followed, as well as guidance from the chemical

sterilant or disinfectant manufacturer, including appropriate dilution

and contact time.

Failures in environmental cleaning and disinfection have led to

transmission of bloodborne pathogens (e.g., hepatitis B virus) and

other infections from one patient to another in hemodialysis units.

Correct cleaning and disinfection of environmental surfaces

(including patient chair or bed surfaces, dialysis equipment surfaces,

adjacent tables and work surfaces) must be performed between patient

uses to prevent transmission of dangerous pathogens.

In hemodialysis units, cleaning and disinfection procedures during

patient changeover are particularly prone to error and contribute to

risk of cross-contamination if correct procedures are not observed. At

the end of each dialysis treatment, all surfaces without visible blood

Final Version 1.1 Page 16 of 299

TAG

REGULATION

INTERPRETIVE GUIDANCE

NUMBER

should be cleaned following the low level disinfection protocol using

soap, detergent or detergent germicide. For visible blood, the

intermediate-level disinfection protocol must be followed, which

requires the area be immediately cleaned with a cloth soaked with

tuberculocidal disinfectant or 1:100 dilution of bleach (300-600 mg/L

free chlorine), following the manufacturer’s direction for contact time.

Gloves must be worn, and the used cloth placed into a leak proof

container. After cleaning up all visible blood, a disinfectant must be

applied a second time using a new cloth or towel. No patient should

be at the station during this time.

For each “station” (i.e., the machine, the purified water connection,

dialysate concentrate container(s) or connection(s), and the treatment

chair), the completion of one patient's treatment and post-dialysis care

must be separated by enough time from the initiation of the next

patient’s care to allow correct disinfection. If the previous patient

remains in the treatment chair while the machine is prepared for the

next patient, extreme caution must be employed to prevent cross-

contamination.

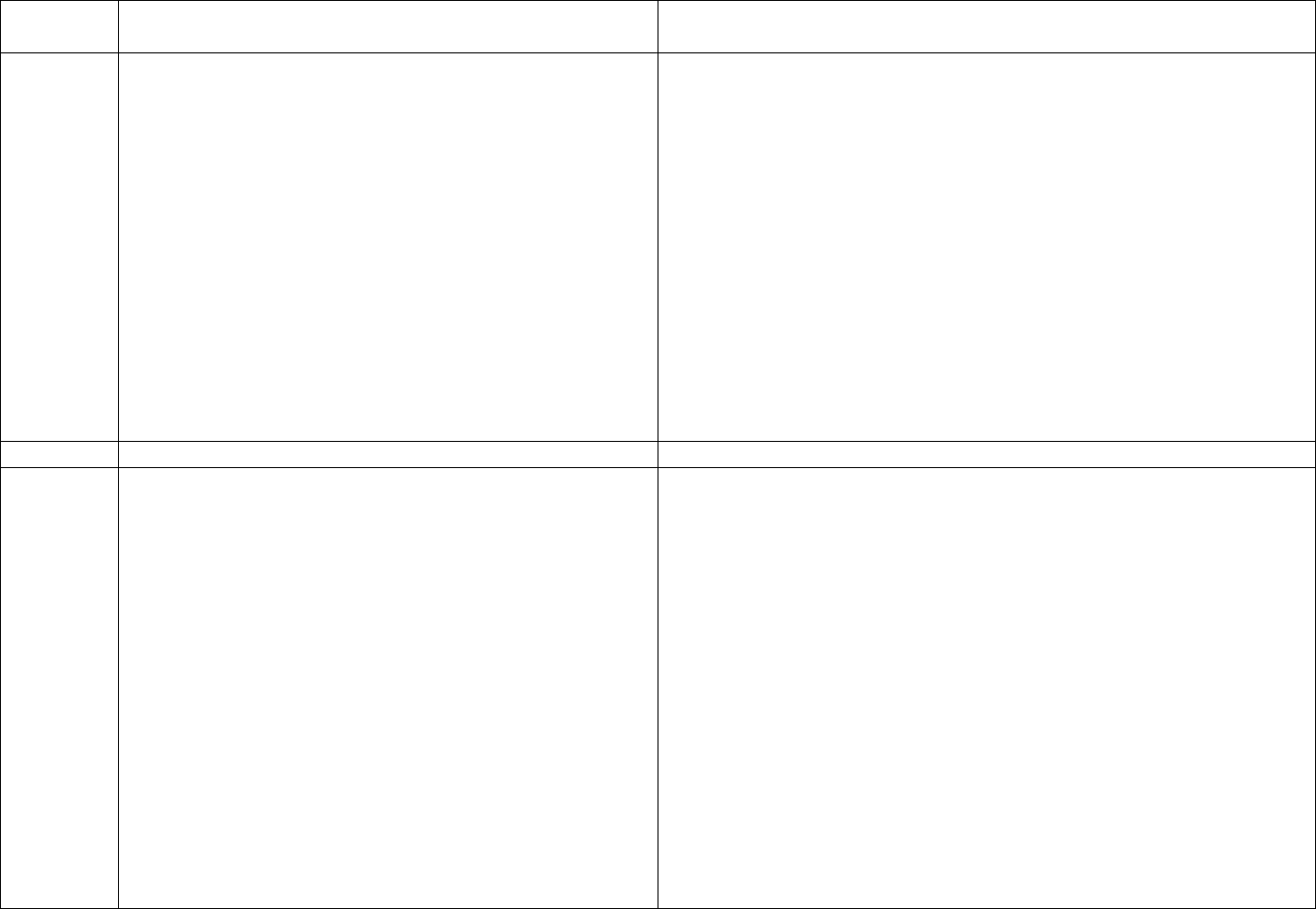

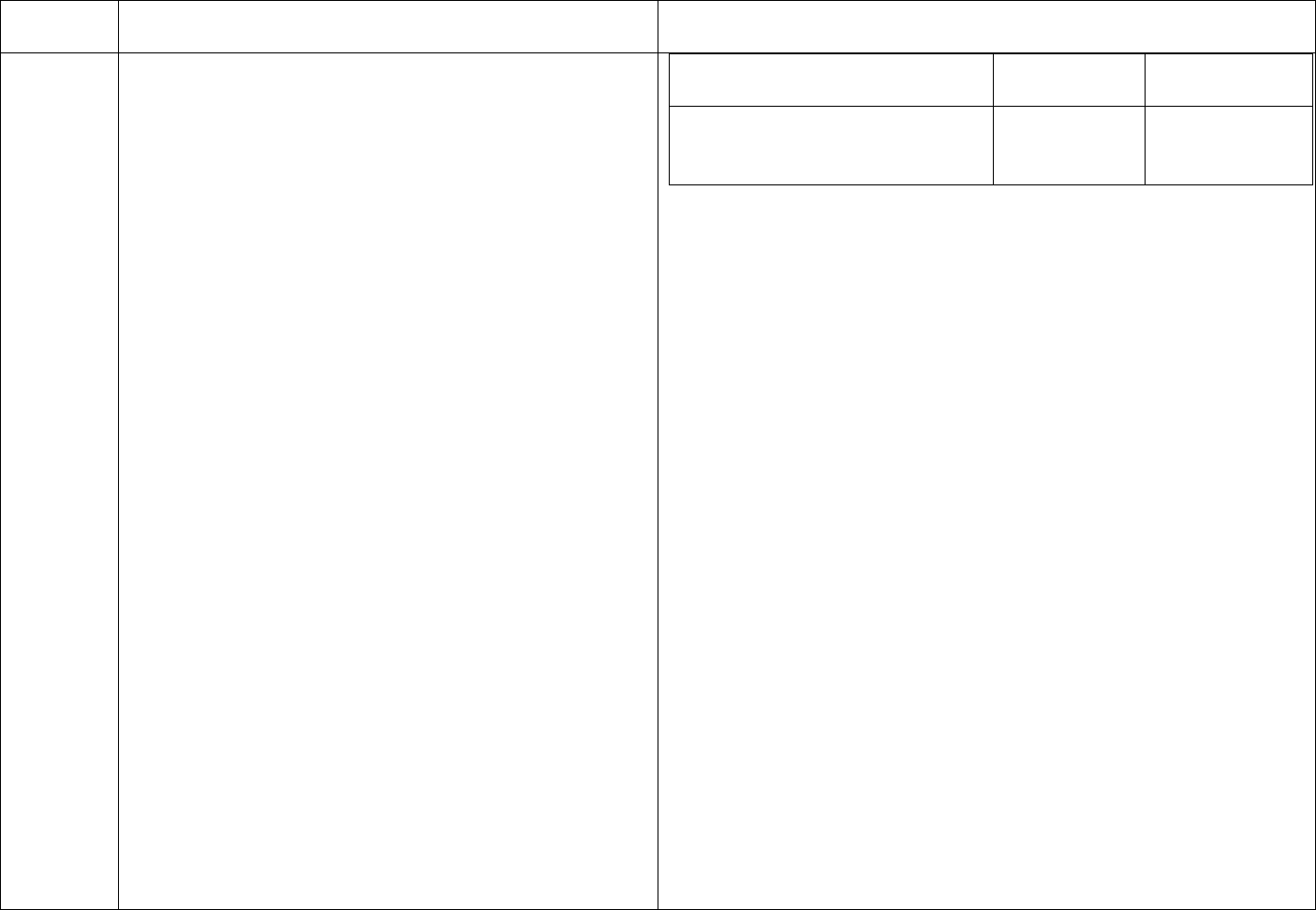

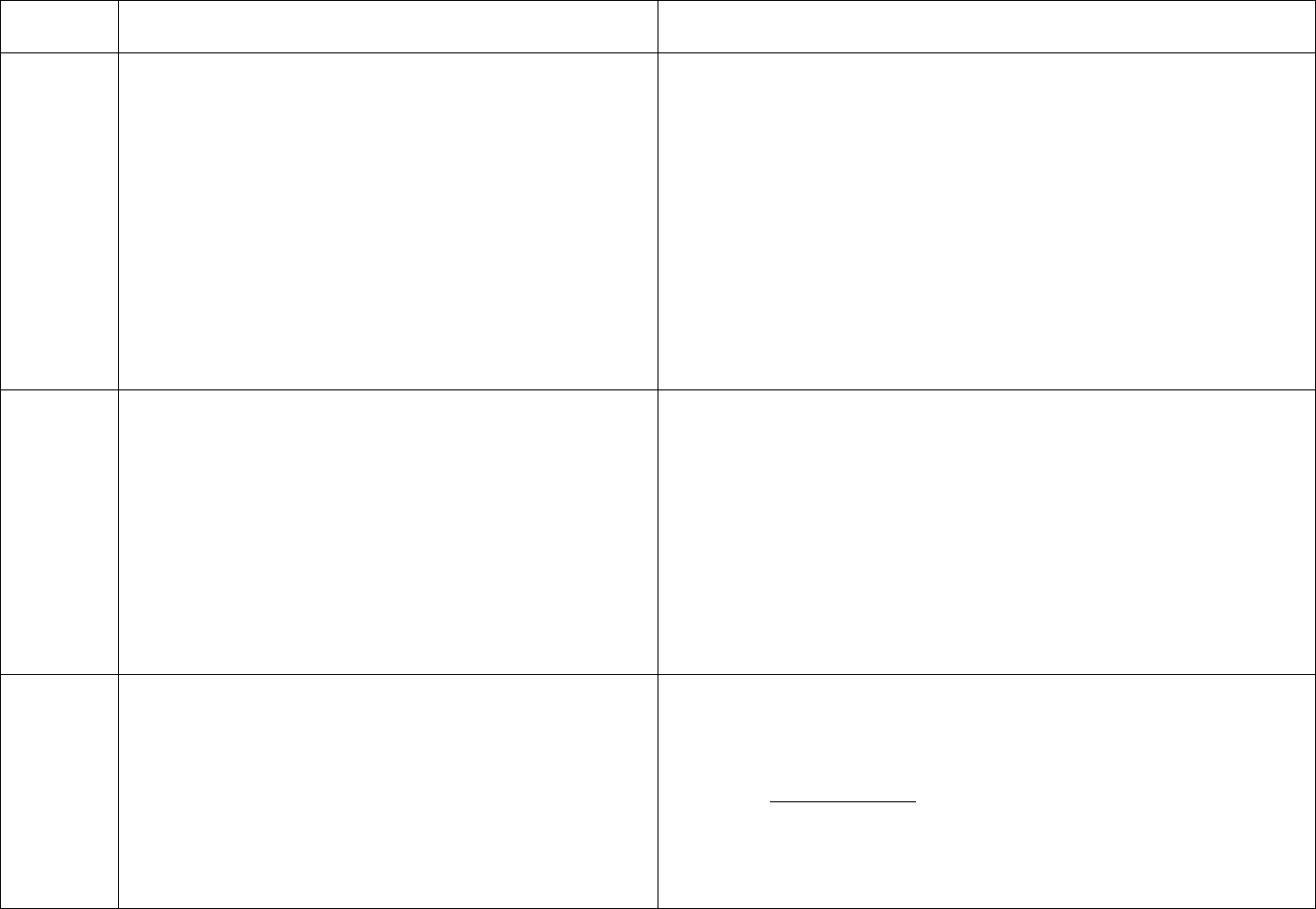

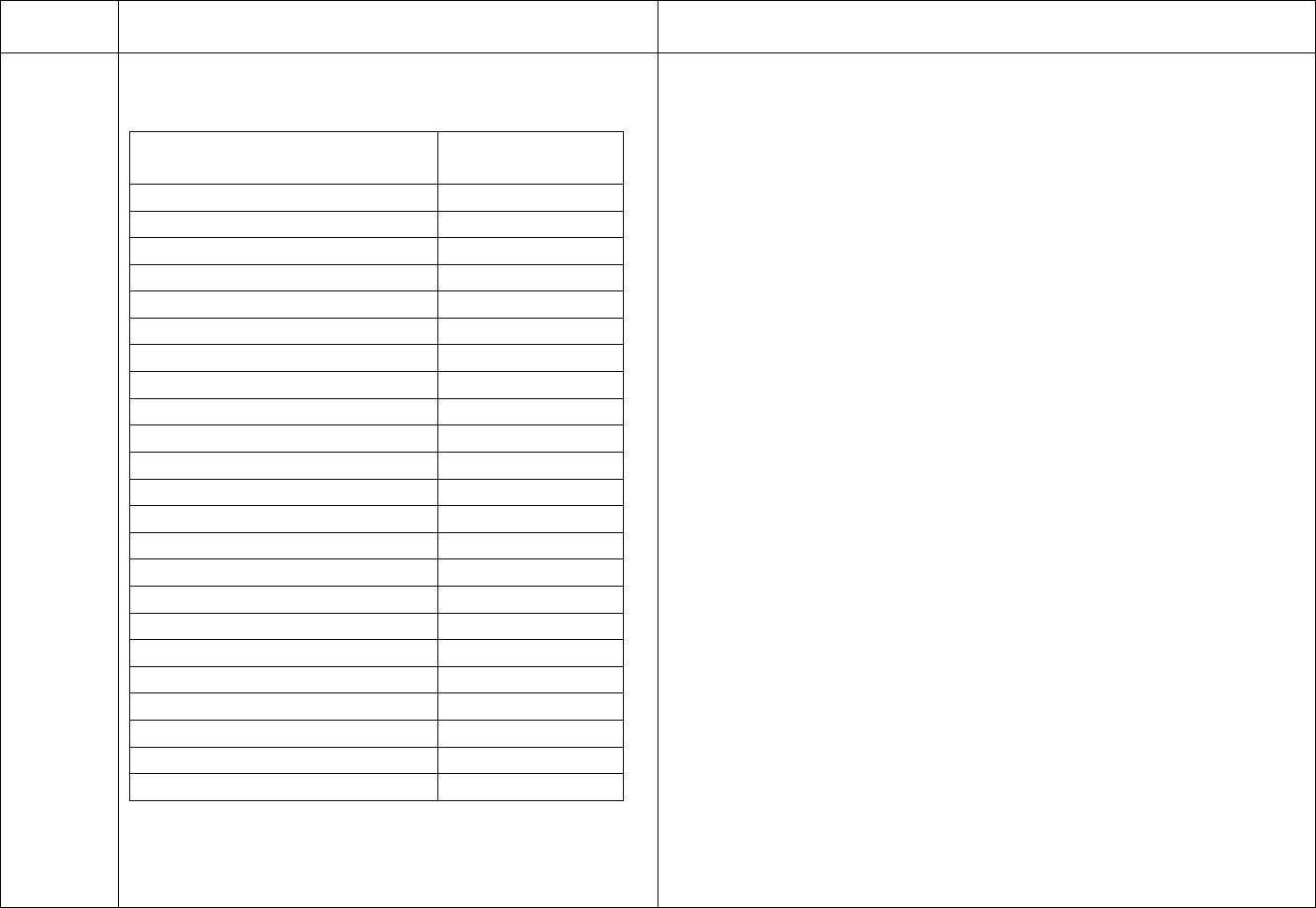

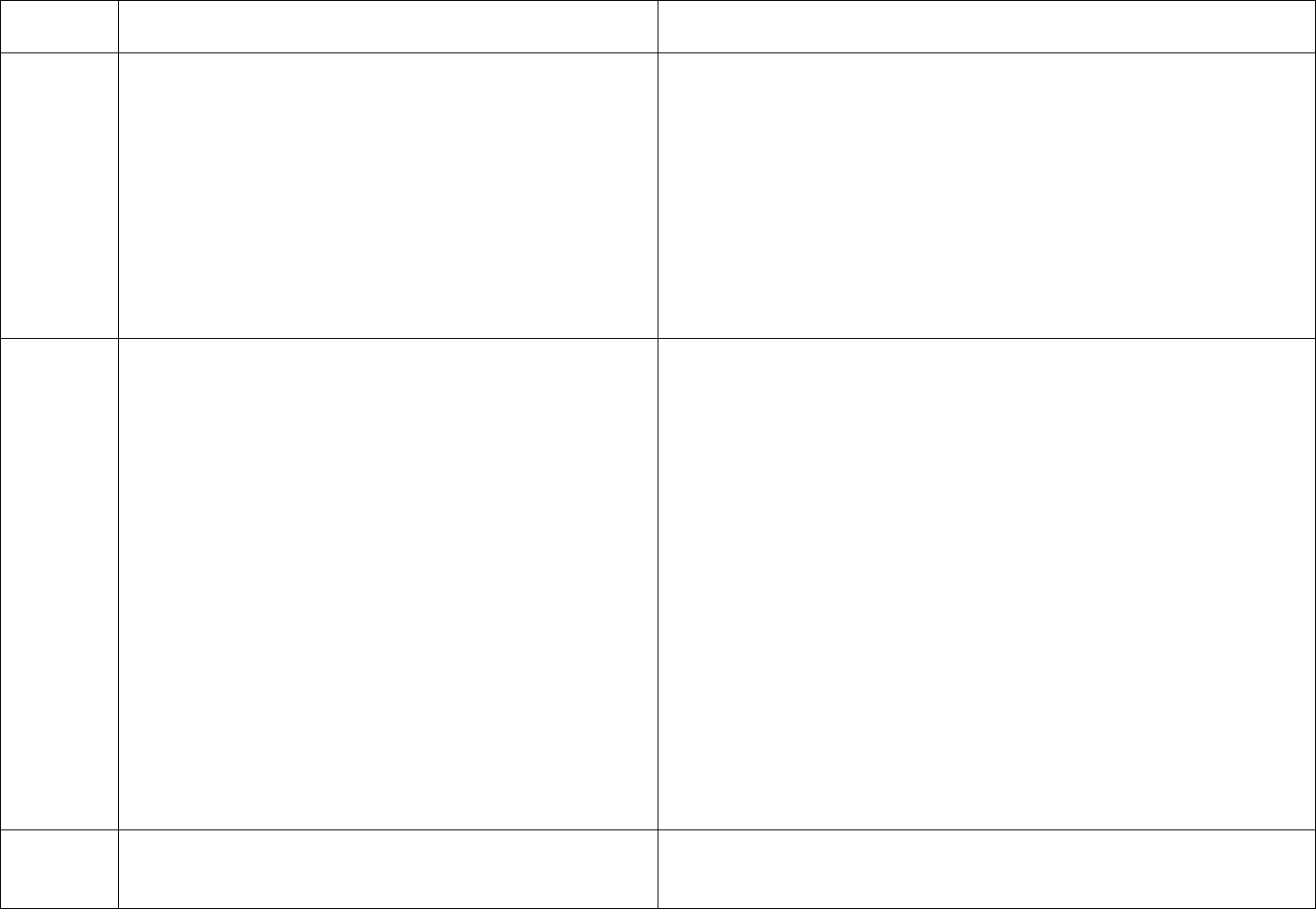

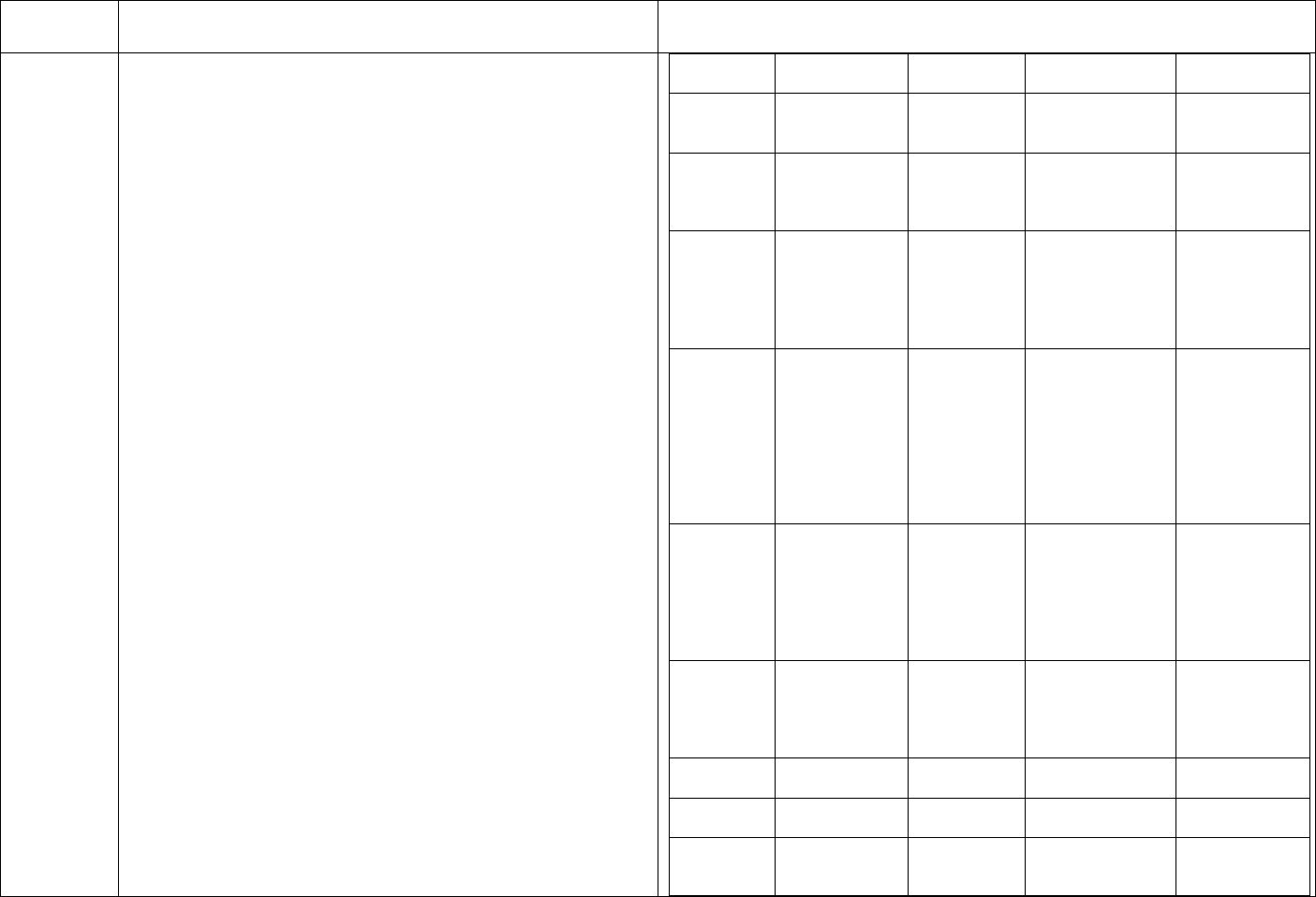

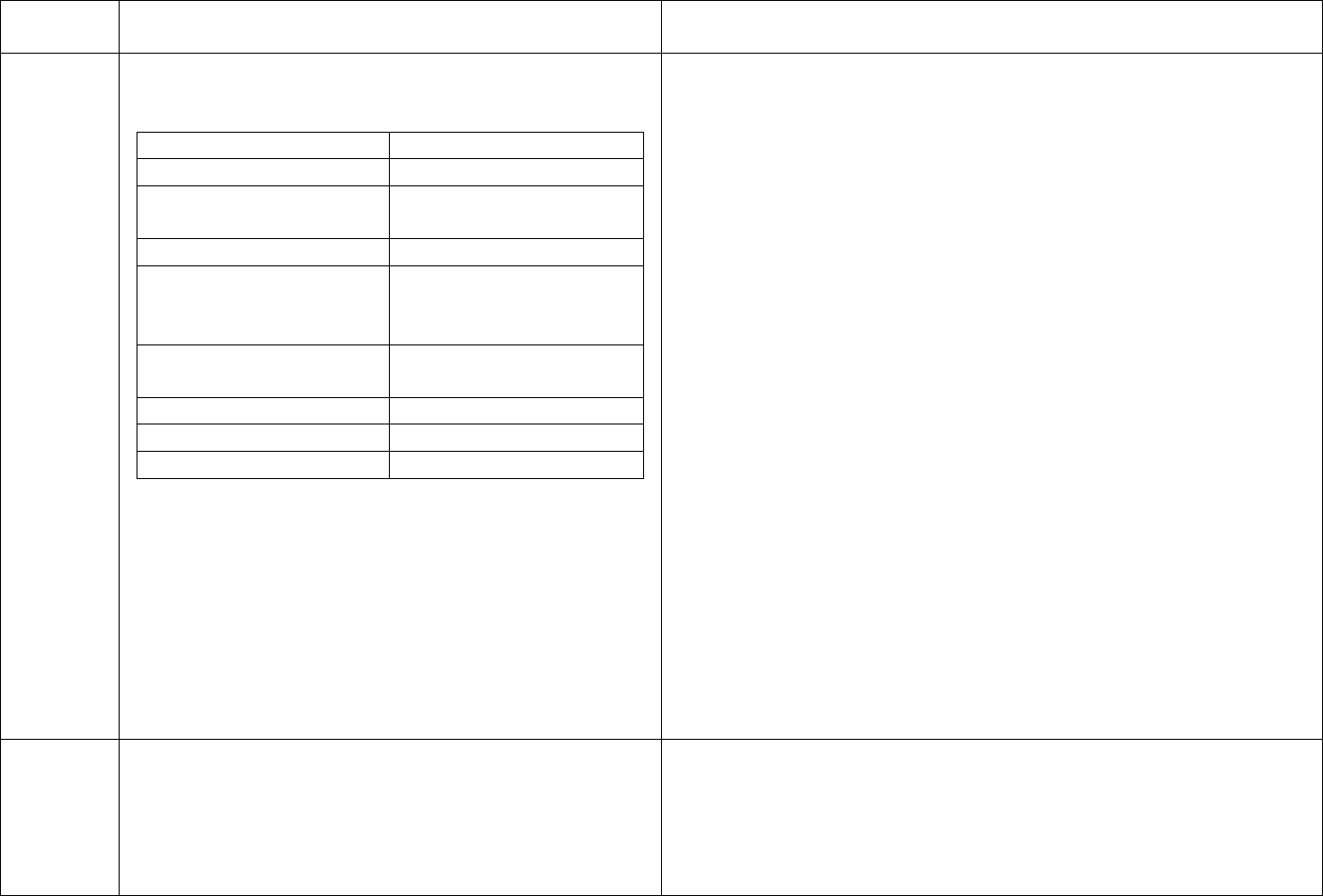

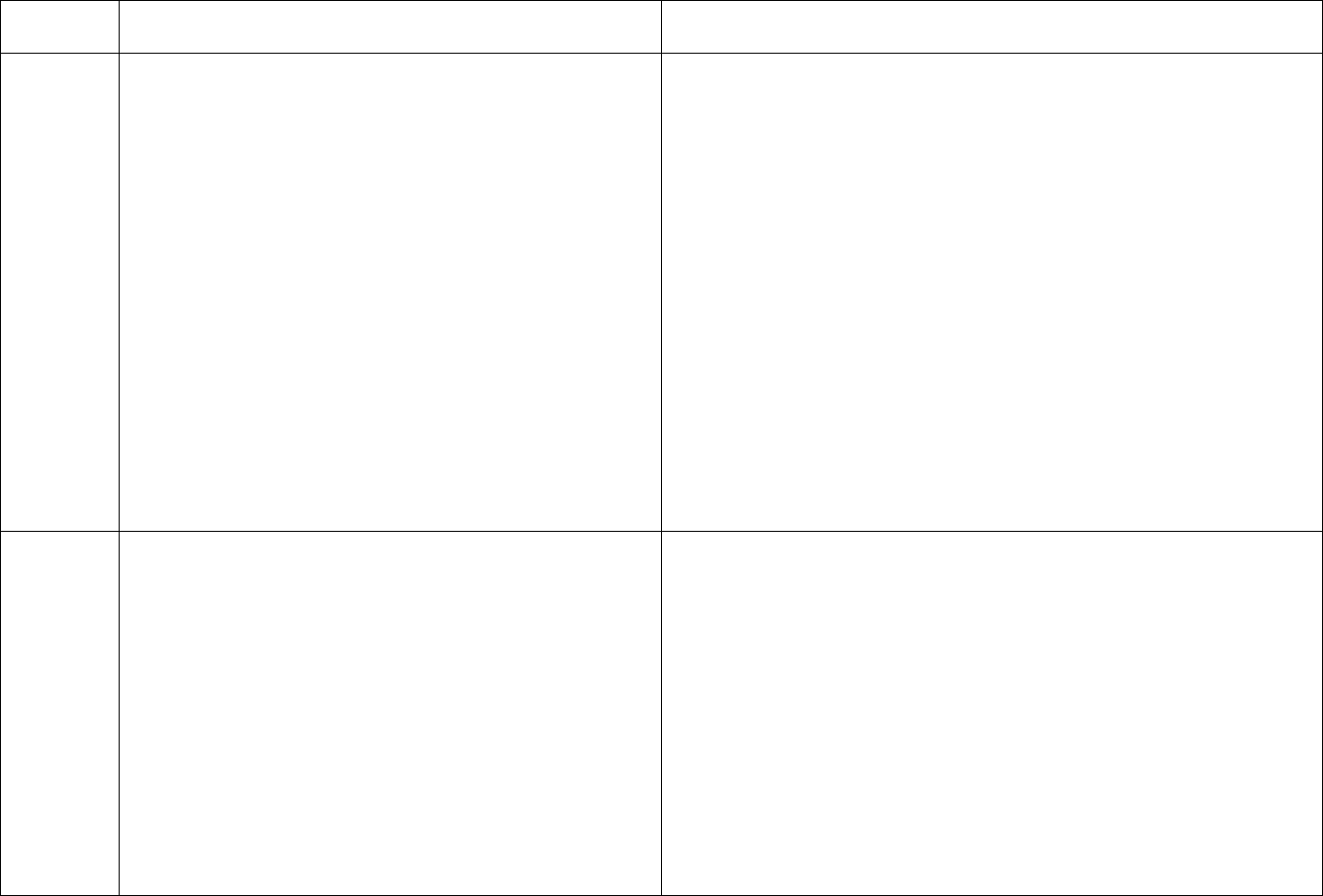

CDC Table 2. Disinfection procedures recommended for

commonly used items or surfaces in hemodialysis units

Intermediate-

Low-Level Level

Item or Surface

Disinfection*

Disinfection*

Gross blood spills or items

contaminated with visible blood

X

Hemodialyzer port caps

X

Interior pathways of dialysis

machine

X

Water treatment and distribution

X

†

system

X

X

§

Scissors, hemostats, clamps,

X

Final Version 1.1 Page 17 of 299

TAG

REGULATION

INTERPRETIVE GUIDANCE

NUMBER

blood pressure cuffs,

stethoscopes

Environmental surfaces,

including exterior surfaces of

hemodialysis machines

X

*Careful mechanical cleaning to remove debris should always be done

before disinfection

†Water treatment and distribution systems of dialysis fluid

concentrates require more extensive disinfection if significant biofilm

is present within the system

§ If item is visibly contaminated with blood, use a tuberculocidal

disinfectant

Blood spills in the treatment area and other areas, such as the waiting

room and patient bathroom, need to be cleaned effectively and

immediately, or as soon as possible given the patient care situation. If

a blood spill occurs, staff must clean it up immediately [or as soon as

possible] with a cloth soaked with a tuberculocidal disinfectant or a

1:100 or stronger dilution of bleach (300-600 mg/L free chlorine) (i.e.,

intermediate-level disinfection). After all visible blood is cleaned,

staff should use a new cloth or towel to apply disinfectant a second

time.

“Intermediate-level disinfection” means disinfection that kills bacteria

and most viruses and is accomplished by using a tuberculocidal

“hospital disinfectant” or a 1:100 dilution of bleach (300-600 mg/L

free chlorine). “Low-level disinfection” means disinfection that kills

most bacteria and is accomplished by using general purpose

disinfectants.

At the end of each patient treatment, the staff should clean and

disinfect the dialysis station. Special attention should be given to

cleaning control panels on the dialysis machines, the treatment chairs

Final Version 1.1 Page 18 of 299

TAG

NUMBER

REGULATION

INTERPRETIVE GUIDANCE

and other surfaces that are frequently touched and potentially

contaminated with patients' blood. The staff should discard all fluids

and clean and disinfect all surfaces of the containers associated with

the prime waste (including containers attached to the machines) after

each treatment.

After each treatment, the staff needs to clean and disinfect medical

devices and equipment. Items such as scissors, hemostats, clamps,

stethoscopes, and blood pressure cuffs need to be cleaned and

disinfected between patient uses. If the item is visibly contaminated

with blood, an intermediate-level disinfectant must be used.

Staff must appropriately clean and disinfect the internal circuits of the

dialysis machines. Single-pass machines may be rinsed and

disinfected at the beginning or end of each day, while batch

recirculating machines must be drained, rinsed and disinfected after

each use. If a blood leak occurs, the manufacturer’s recommendations

for additional disinfection should be followed.

A facility should document procedures for the dialysis machine

disinfection, including testing for residual disinfectant.

No tag

(3) Patient isolation procedures to minimize the spread of

infectious agents and communicable diseases;

This is an information tag. At the time of publication of these

regulations, isolation procedures required by the CDC were related to

the care and treatment of HBV+ patients. For guidance and references

to isolation, refer to the individual tags related to isolation which are

provided below in this section.

V124

CDC RR-5 Requirements as Adopted by Reference

42 CFR 494.30 (a)(1)(i)

Routine Testing for Hepatitis B

The HBV serological status (i.e. HBsAg, total anti-HBc

and anti-HBs) of all patients should be known before

Clarification of terminology: “HBsAg positive” is used synonymously

with “HBV+” meaning that the person has tested positive for the

presence of Hepatitis B surface antigen. “HBsAg negative” is used

synonymously with “HBV-” meaning that the person does not have

the Hepatitis B surface antigen. “HBV susceptible” means that the

person does not have sufficient Hepatitis B surface antibody levels to

achieve immunity to the virus. “HBV immune” means the person has

Final Version 1.1 Page 19 of 299

TAG

REGULATION

INTERPRETIVE GUIDANCE

NUMBER

admission to the hemodialysis unit.

sufficient Hepatitis B surface antibodies to achieve immunity to the

virus.

Routinely test all patients [as required by the referenced

schedule for routine testing for Hepatitis B Virus]. According to CDC, although the incidence of HBV infection is low

Promptly review results, and ensure that patients are among chronic hemodialysis patients, preventing transmission

managed appropriately based on their testing results. depends on timely detection of patients converting from HBsAg

negative to HBsAg positive and rapid implementation of isolation

procedures before cross-contamination can occur.

In order to prevent the transmission of Hepatitis B among ESRD

patients, all new patients should be tested and their HBV serologic

status (i.e., HBsAg, total anti-HBc, and anti-HBs results) should be

known prior to admission for treatment. If the results of this testing

are not known at admission because of an emergency situation, the

patient should be tested immediately upon intake and results known

within 7 days of admission.

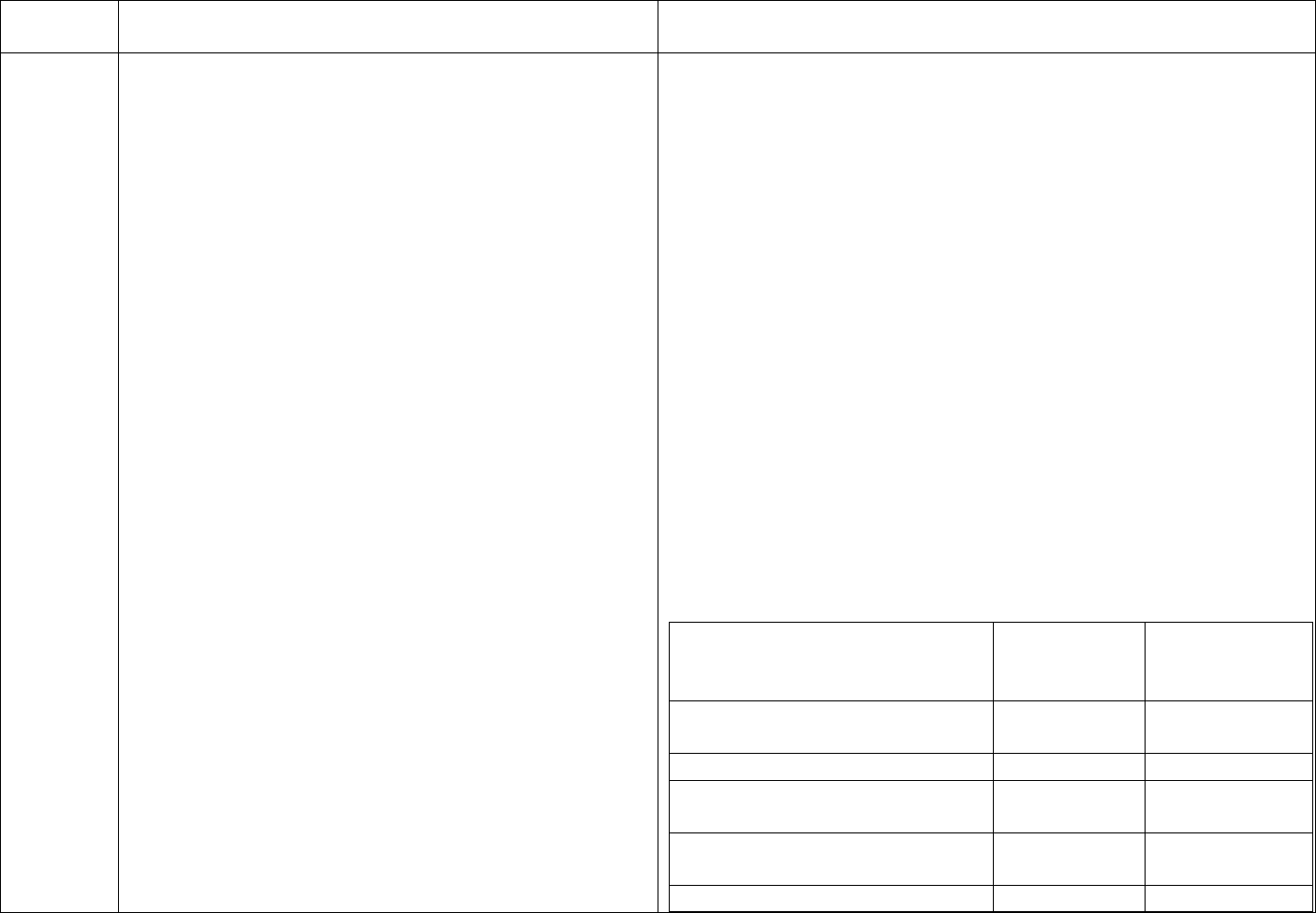

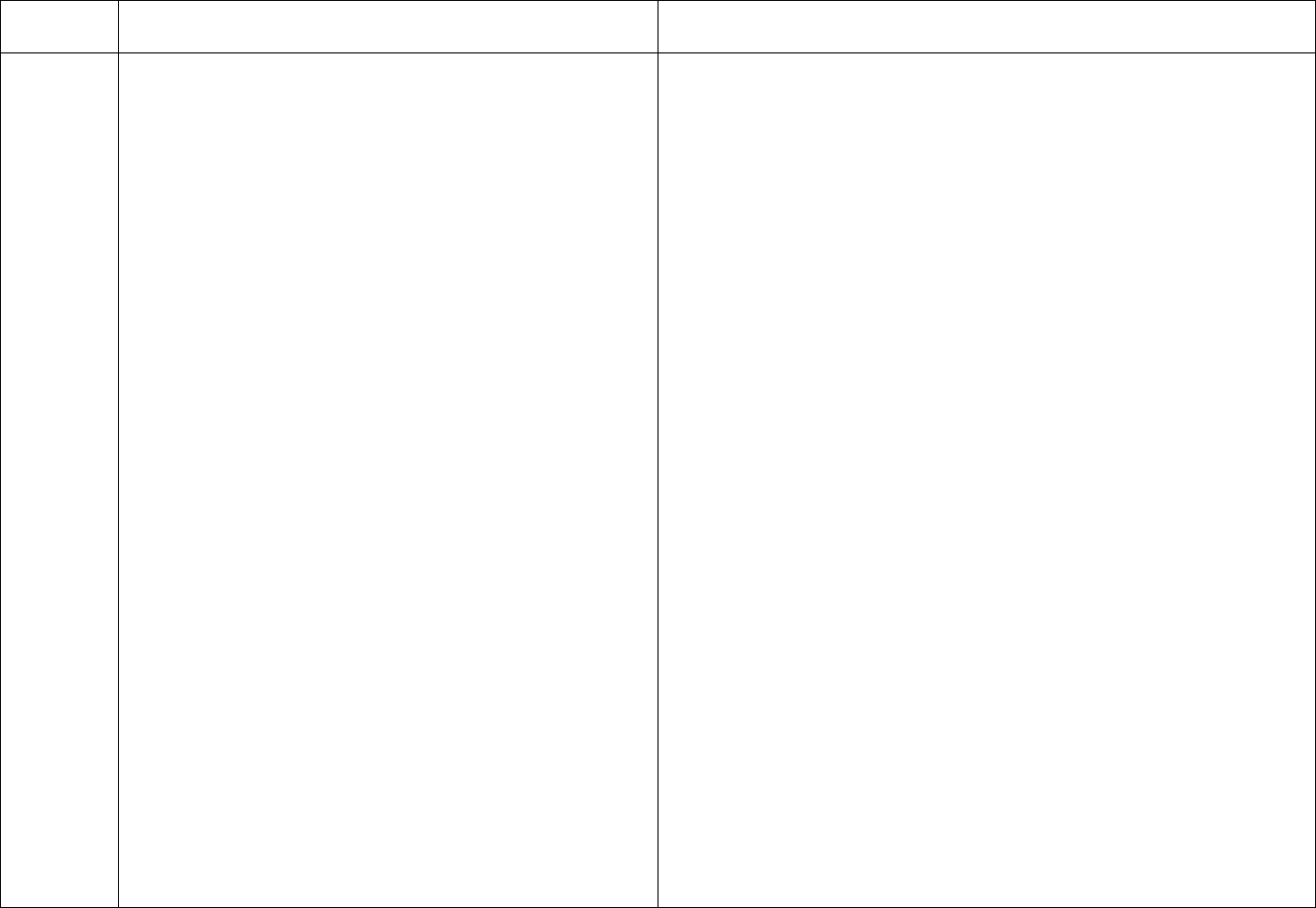

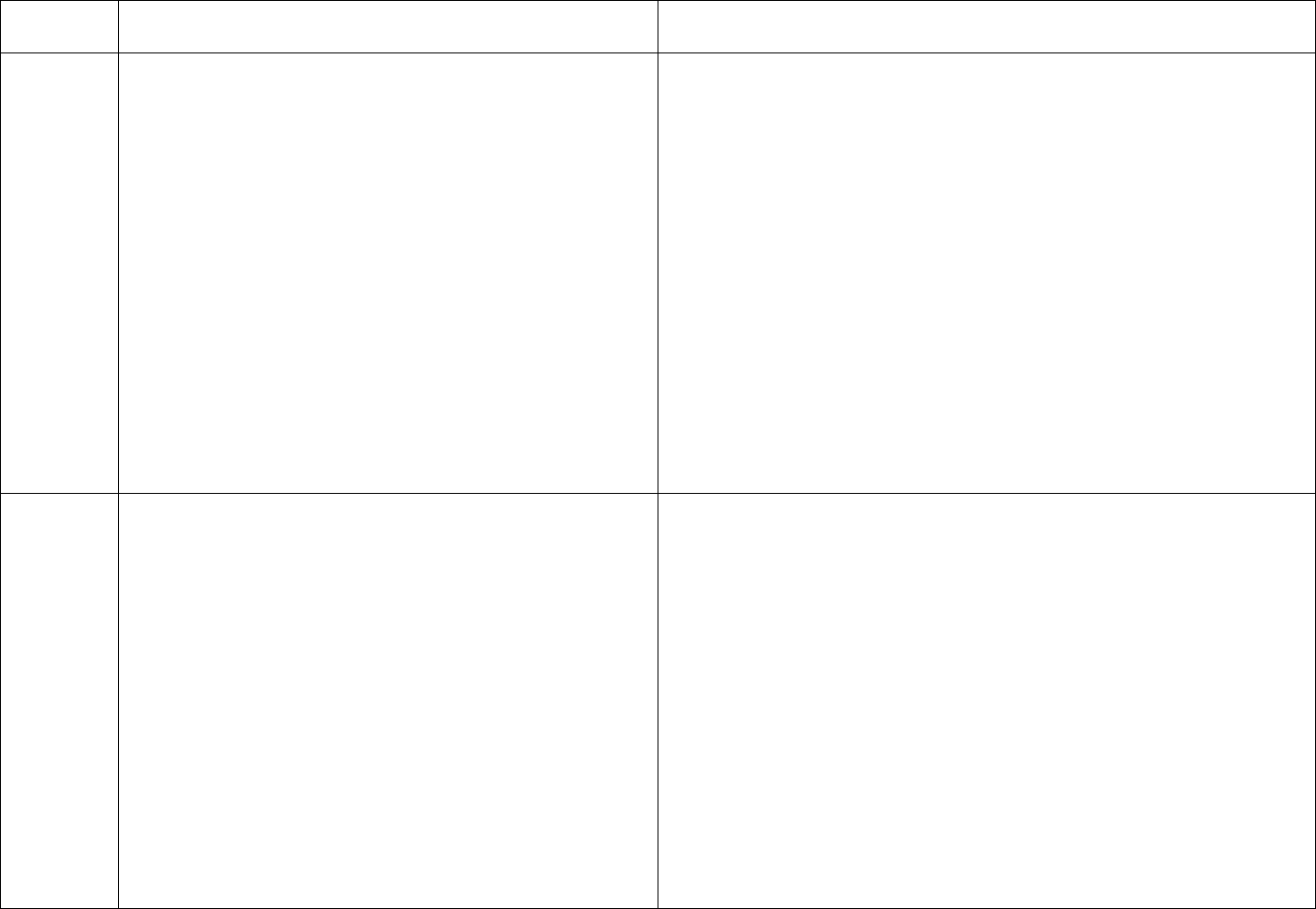

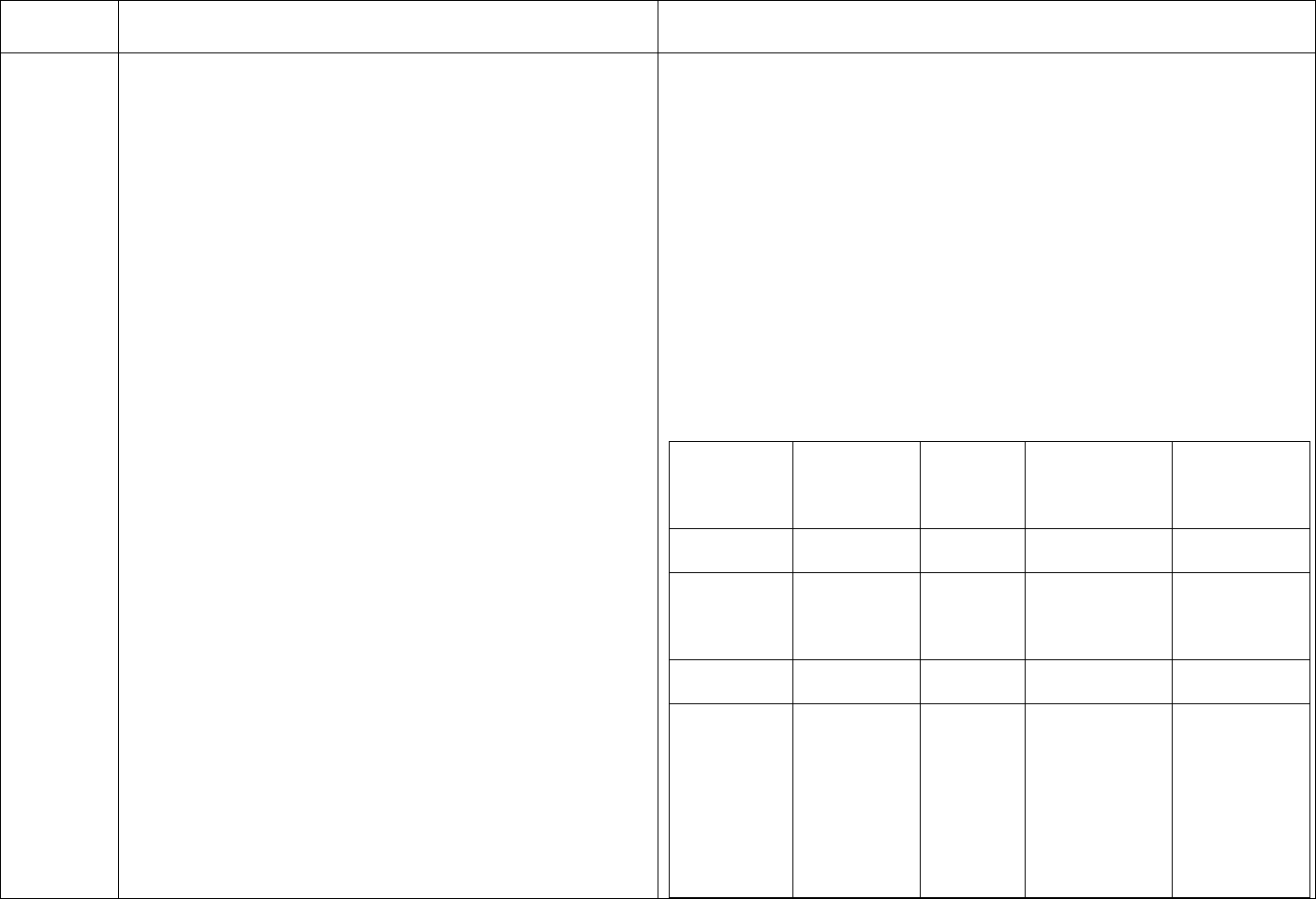

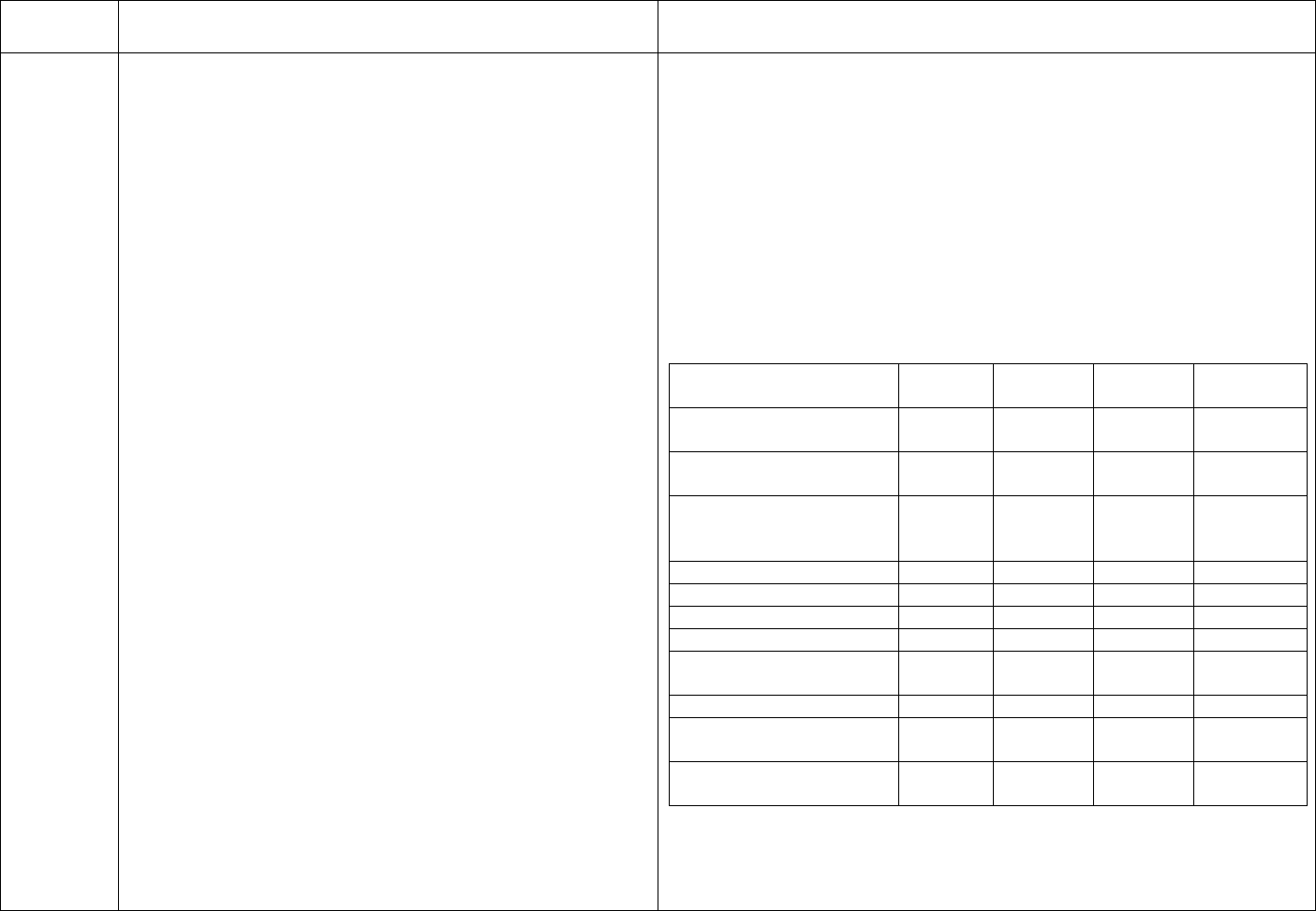

CDC’s schedule for Hepatitis B testing is below:

Schedule for Routine Testing for Hepatitis B Virus (HBV)

Infections

On

Semi-

Patient Status

Admission

Monthly

annual

Annual

HBsAg,*

Anti-HBc*

(total),

All patients

Anti-HBs,*

HBV-

susceptible,

including

nonresponders

to vaccine

HBsAg

Anti-HBs

Anti-

Final Version 1.1 Page 20 of 299

TAG

REGULATION

INTERPRETIVE GUIDANCE

NUMBER

positive

HBs

(≥10 mIU/mL),

anti-HBc

negative

Anti-HBs and

anti-HBc

positive

No additional HBV testing needed

* Results of HBV testing should be known before the patient begins

dialysis.

† HBsAg = hepatitis B surface antigen; Anti-HBc = antibody to

hepatitis B core antigen; Anti-HBs = antibody to hepatitis B surface

antigen.

HBV-Susceptible Patients. Susceptible patients should begin receipt

of hepatitis B vaccine immediately upon admission. Test susceptible

patients monthly for HBsAg, including those who a) have not yet

received hepatitis B vaccine, b) are in the process of being vaccinated,

or c) have not adequately responded to vaccination. Note that, while

the patient’s anti-HBs is <10 mIU/mL, he/she is considered

susceptible to hepatitis B, and should be tested for HBsAg monthly.

Follow-Up of Vaccine Responders. Retest patients who respond to

the vaccine annually for anti-HBs.

HBV-Infected Patient. Chronically infected patients do not require

any routine follow-up testing for purposes of infection control. Annual

testing for HBsAg is reasonable to detect the small percentage of

HBV-infected patients who might lose their HBsAg.

HBV-Immune Patients. Annual anti-HBs testing of patients who are

positive for anti-HBs (>10 mIU/mL) and negative for anti-HBc

determines the need for booster doses of vaccine to ensure that

protective levels of antibody are maintained. Follow-up testing after

Final Version 1.1 Page 21 of 299

TAG

NUMBER

REGULATION

INTERPRETIVE GUIDANCE

booster doses of vaccine are given is not recommended, nor is routine

follow-up testing necessary for patients who are positive for both anti-

HBs and anti-HBc.

A facility should have systems in place for communicating these test

results to other units or hospitals when patients are transferred for

care.

V125

CDC RR-5 Requirements as Adopted by Reference

42 CFR 494.30 (a)(1)(i)

Routine Testing for Hepatitis B: seroconversion

When a seroconversion occurs, review all patients’

routine laboratory test results to identify additional cases.

Investigate potential sources for infection to determine if

transmission might have occurred within the dialysis

unit, including review of newly infected patients’ recent

medical history (e.g., blood transfusion, hospitalization),

history of high-risk behavior (e.g., injecting-drug use,

sexual activity), and unit practices and procedures.

According to the CDC, in patients newly infected with HBV, HBsAg

often is the only serologic marker initially detected. HBsAg-positive

seroconversions must be reported to the State or local health

department as required by law or regulation. Patients with a positive

HBsAg must be isolated. Patients newly identified with a positive

HBsAg should be evaluated for the need for counseling, medical

evaluation, and vaccination of contacts. Repeat HBsAg testing should

be conducted and patient should be tested for anti-HBc (including

IgM anti-HBc) 1–2 months later. Six months later, the facility should

repeat HBsAg testing and test for anti-HBs to determine clinical

outcome and need for counseling, medical evaluation, and referral of

contacts for vaccination. Patients who become HBsAg negative are no

longer infectious and can be removed from isolation.

If there have been any seroconversions since last survey, there should

be documentation of actions taken in response. Recognize that

seroconversions should be relatively rare, and each seroconversion

should be carefully analyzed for any potential that transmission

occurred within the dialysis unit.

V126

CDC RR-5 Requirements as Adopted by Reference

42 CFR 494.30 (a)(1)(i)

Hepatitis B Vaccination

Vaccinate all susceptible patients and staff members

against hepatitis B.

According to the CDC, hepatitis B vaccination is recommended for all

susceptible chronic hemodialysis patients and staff members, whether

or not the facility accepts HBV+ patients. OSHA mandates that each

facility provide HBV vaccine to all susceptible staff members.

Hepatitis B vaccination is also recommended for Stage 1-5 chronic

kidney disease patients not yet on dialysis and peritoneal dialysis (PD)

and home hemodialysis (home HD) patients because they might

Final Version 1.1 Page 22 of 299

TAG

NUMBER

REGULATION

INTERPRETIVE GUIDANCE

require in-center hemodialysis. While not a requirement, best practice

would suggest that the home training nurse advise anyone who assists

in the home hemodialysis treatment of an HBV+ patient to ask their

physician to vaccinate them against hepatitis B.

The patient’s physician should refer to the CDC recommendations or

the vaccine literature for guidance in dosing. Higher doses of the

vaccine are recommended for hemodialysis patients due to their

immuno-compromised state.

Since patients and staff have the right to refuse a vaccination, this rule

is interpreted to mean that all susceptible patients and staff are

“offered” an appropriate Hepatitis B vaccination schedule in an

appropriate timeframe. “Appropriate timeframe” means that

vaccinations should be offered and initiated at hire for employees and

upon admission or earlier for patients, and the course completed

according to the timeline suggested by the manufacturer of the

vaccine.

Personnel files should demonstrate compliance with this regulation:

OSHA requires facilities to maintain a record of their employee’s

Hepatitis B immunization history and to contact past employers to

obtain records of vaccination, if applicable. OSHA requires these

records be maintained for 30 years after the person leaves

employment. If the employee states he/she has been vaccinated, but

the records are not obtainable, the personnel record should include a

statement attesting to the employee having received the vaccine with

dates (or approximate dates) signed by the employee.

Patient medical and personnel records respectively must show

whether susceptible patients and staff are offered hepatitis B

vaccination. There must be a system in place to track vaccination

administration to assure completion of the ordered course.

Final Version 1.1 Page 23 of 299

TAG

NUMBER

REGULATION

INTERPRETIVE GUIDANCE

V127

CDC RR-5 Requirements as Adopted by Reference

42 CFR 494.30 (a)(1)(i)

Hepatitis B Screening: Patients and Staff

Test all vaccines [patients and staff] for anti-HBs 1-2

months after last primary vaccine dose.

-- If anti-HBs is <10 mIU/mL, consider patient or staff

member susceptible, revaccinate with an additional three

doses, and retest for anti-HBs.

-- If anti-HBs are ≥10 mIU/mL, consider immune, and

retest patients annually.

-- Give booster dose of vaccine to patients if anti-HBs

declines to <10 mIU/mL and continue to retest patients

annually.

According to the CDC, all vaccinees (patients and staff) must be

tested for anti-HBs 1–2 months after the last primary vaccine dose to

determine their response to the vaccine. Patients and staff members

who do not respond to the primary vaccine series should be

revaccinated with a full course of vaccine and retested for response.

No additional doses of vaccine are warranted for those who do not

respond to the second series. Patients who require a booster dose of

the HBV vaccine should not be assigned to a staff member

concurrently caring for HBV+ positive patients.

The CDC defines an adequate response to vaccination as a laboratory

result of ≥10 mIU/mL anti-HBs. The laboratory performing the testing

for anti-HBs must be able to define a 10 mIU/mL concentration.

Results should be reported as a numeric value; a result of “positive” or

“negative” is not sufficient. Some manufacturers of anti-HBs assays

consider a level of anti-HBs that is slightly higher than 10mIU/mL to

be protective. For these assays, the higher level of titer considered to

be protective by the manufacturer of the kit should be used to

determine whether or not the patient or staff member is immune.

Primary nonresponders to vaccination who are HBsAg negative

should be considered susceptible to HBV infection.

Patients who respond to the vaccine should be retested annually for

anti-HBs. If anti-HBs declines to <10 mIU/mL, these patients should

receive a booster dose of hepatitis B vaccine and continue to be

retested for anti-HBs annually. Retesting immediately after the

booster dose is not necessary.

For staff members who initially respond to the vaccine, neither

booster doses of vaccine nor periodic serologic testing to monitor

antibody concentrations are necessary.

Final Version 1.1 Page 24 of 299

TAG

NUMBER

REGULATION

INTERPRETIVE GUIDANCE

The facility and the responsible physicians should consult the CDC

recommendations on dosing and revaccination.

V128

CDC RR-5 Requirements as Adopted by Reference

42 CFR 494.30 (a)(1)(i)

Isolation of HBV+ Patients

To isolate HBsAg positive patients, designate a separate

room for their treatment.

For existing units in which a separate room is not

possible, HBsAg positive patients should be separated

from HBsAg susceptible patients in an area removed

from the mainstream of activity.

Beginning February 9, 2009, all new facilities must have a separate

isolation room unless the facility has obtained a waiver from CMS for

this requirement. See V129 for the details of this requirement.

According to the CDC, HBV+ patients must dialyze in a separate

isolation room during dialysis to prevent contact and transmission by

contact with blood spills, splattering, or spurting of blood and other

body fluids.

A separate room with a door is required both to contain any spurting

of blood, body fluids, and other contaminates and to prevent cross-

transmission that can occur as a result of environmental

contamination. HBV is stable in the environment and can survive on

surfaces (and remain infectious) for at least 1 week. Since Hepatitis B

is not airborne, the walls of the room do not need to reach the ceiling,

but would need to go to the floor in order to contain blood spills and

the door must be closed during times when blood spurting or

spattering is possible, e.g., at initiation and termination of treatment.

The walls need to allow visual monitoring of the patients in the room

(unless a staff member is continually present in the room) and to

contain any potential blood or fluid spills or spurts.

A separate room is the safer and preferred method of isolation;

however, “existing” facilities, meaning those facilities that were

treating HBV+ patients as of the effective date of the regulations, i.e.

October 14, 2008, and that were using a separate area rather than a

separate room, may continue to use the separate “isolation” area,

unless they are expanding the physical location, in which case they

must add an isolation room or obtain a waiver of the requirement. If

an existing facility uses a designated isolation area rather than a room,

the area used for HBV+ patients must be separated from other stations

Final Version 1.1 Page 25 of 299

TAG

NUMBER

REGULATION

INTERPRETIVE GUIDANCE

by a space at least equivalent to the width of one hemodialysis station.

The “isolation” station could be an “end of row” station to facilitate

the separation of the area from the mainstream of the dialysis

facility’s activities and to decrease the number of adjacent dialysis

stations.

If there are current HBV+ patients on census, the isolation area/room

and equipment cannot be used for HBV- patients on other shifts or

days due to the risk of cross-contamination. When any HBV+ patients

are no longer on census, the “isolation” area/room may be terminally

cleaned, disinfected and used for HBV- patients.

Existing units, currently without HBV+ patients, that accept HBV+

patients after the effective date of these regulations may establish a

separate area (as described above) for the care of these patients. Any

facility which expands its physical capacity after February 9, 2009

must include an isolation room or secure a waiver. See V129.

Every facility must have the capacity to separate potentially HBV+

patients during treatment. Existing units which do not currently accept

or treat HBV+ patients may have a transfer agreement with a local

chronic facility which has capacity for isolation stations. If there is no

local facility available to accept such transfers, the existing facility

must establish an isolation room or area for use with HBV+ patients.

If an HBV+ patient chooses home dialysis, precautions must be

exercised during the training of that patient to prevent potential cross-

contamination of the training environment and other home patients.

These could include conducting the training in the patient’s home,

rather than at the dialysis facility, or limiting the use of the training

space to the HBV+ patient until training is completed. Different

precautions would be necessary depending on the modality: home HD

vs. PD. Relatives or other individuals who assist with dialysis for an

Final Version 1.1 Page 26 of 299

TAG

NUMBER

REGULATION

INTERPRETIVE GUIDANCE

HBV+ patient should be instructed to ask their physician regarding

vaccination against hepatitis B infection.

V129

(ii) When dialysis isolation rooms as required by (a)(1)(i)

are available locally that sufficiently serve the needs of

patients in the geographic area, a new dialysis facility

may request a waiver of such requirement. Isolation

room waivers may be granted at the discretion of, and

subject to, additional qualifications as may be deemed

necessary by the Secretary.

As of February 9, 2009, all new facilities must have an isolation room

or have been granted a waiver of this requirement from CMS by

showing there is sufficient capacity in their geographic area for

isolation rooms. New facilities that have not obtained approval for all

required building permits or have not completed the required plan

reviews in a jurisdiction that does not require building permits prior to

the effective date of these regulations (October 14, 2008), must either

provide a separate isolation room by February 9, 2009, or obtain a

waiver of the requirement for an isolation room. Waiver requests,

including information on geographical accessibility of isolation

rooms, should be referred to the applicable CMS Regional Office.

V130

CDC RR-5 Requirements as Adopted by Reference

42 CFR 494.30 (a)(1)(i)

Isolation of HBV+ Patients

To isolate HBsAg positive patients,… dedicate

machines, equipment, instruments, supplies, and

medications that will not be used by HBV susceptible

patients.

Separate dedicated supplies and equipment, including blood glucose

monitors, must be used to provide care to the HBV+ patient. All

supplies used in the isolation room/area, such as clamps, blood-

pressure cuffs, testing reagents, etc., should be labeled "isolation" and

not routinely removed from the isolation room/area.

Refillable concentrate containers must be surface disinfected at the

completion of each treatment. Refillable concentrate containers may

be kept in the isolation area and refilled at the door or removed for

cleaning and disinfection. In the disinfection area, the “isolation”

container(s) and pick-up tube(s) must be segregated in a dedicated,

designated area away from all other containers and pick-up tubes. If

the container/pick-up tube is to be rotated out of the isolation area, it

must be bleached before subsequent use.

Separate gowns should be used in the isolation area and removed

before leaving the isolation area/room. Any one entering the isolation

area/room during the patient’s treatment must wear a protective gown.

HBV+ patients must undergo dialysis on dedicated machines. Because

Final Version 1.1 Page 27 of 299

TAG

NUMBER

REGULATION

INTERPRETIVE GUIDANCE

of the risk of cross-contamination, facilities should avoid switching

equipment used for HBV+ patients for use with HBV- patients.

Equipment used for HBV+ patients should be reserved for the HBV+

patients unless repair or maintenance is needed, or until all HBV+

patients have been discharged.

Dialyzers for HBV+ patients must not be reused. Refer to V301 under

Reuse.

When the machine is no longer dedicated to an HBV+ patient, internal

pathways of the machine can be disinfected using conventional

protocols, external surfaces cleaned and disinfected and the machine

returned to general use.

V131

CDC RR-5 Requirements as Adopted by Reference

42 CFR 494.30 (a)(1)(i)

Isolation of HBV+ Patients

Staff members caring for HBsAg positive patients should

not care for HBV susceptible patients at the same time,

including during the period when dialysis is terminated

on one patient and initiated on another.

One staff person may care for one or more HBV+ patients and one or

more immune patients at the same time, but may not simultaneously

care for Hepatitis B susceptible patients. Hepatitis B status should be

considered when patients are assigned to stations nearest the isolation

area. If a staff member assigned to care for an HVB+ patient must

concurrently care for someone other than another HBV+ patient, the

additional patient(s) must be HBV immune. Patients who require a

booster dose of the HBV vaccine should not be assigned to a staff

member concurrently caring for HBV+ positive patients. When

possible, only HBV immune staff should be assigned to care for

HBV+ patients.

V132

CDC RR-5 Requirements as Adopted by Reference

42 CFR 494.30 (a)(1)(i)

Infection Control Training and Education

Infection control practices for hemodialysis units:

intensive efforts must be made to educate new staff

members and reeducate existing staff members regarding

these practices.

Training and education in infection control rationales and practices

appropriate to the responsibilities and task assignments of the staff

member at risk for occupational exposure to blood must be provided

initially on employment and periodically, as determined by facility

policy, but at least annually. OSHA mandates dialysis staff receive

bloodborne pathogen training annually and CDC recommends

infection control training initially on employment and annually.

Topics must include (but are not limited to):

Final Version 1.1 Page 28 of 299

TAG

NUMBER

REGULATION

INTERPRETIVE GUIDANCE

End CDC RR-5 Requirements

• Proper hand hygiene technique

• Proper use of personal protective equipment (PPE)

• Infection control practices recommended for hemodialysis units

and differences from Standard Precautions

• Special precautions for HBsAg-positive patients

• Proper infection control techniques for initiation, care, and

maintenance of access sites

• Modes of transmission for bloodborne viruses, pathogenic

bacteria, and other microorganisms as appropriate

• Proper handling, preparation, and administration of parenteral

medications maintaining aseptic technique; and

• Proper methods to clean and disinfect equipment and

environmental surfaces to minimize transmission of

microorganisms.

Staff must demonstrate knowledge of infection control

policies/procedures and practices. Personnel records must reflect staff

having received appropriate infection control training.

V142

(b) Standard: Oversight. The facility must—

(1) Monitor and implement biohazard and infection

control policies and activities within the dialysis unit;

The facility should have written policies and procedures covering the

infection control program and practices including, but not limited to,

isolation and any additional precautions for patients with

communicable diseases with different modes of transmission such as

tuberculosis (TB), influenza, and multidrug resistant organisms. The

facility must review practices and update policies and procedures as

needed to ensure infection control practices are rigorously followed.

V143

(2) Ensure that clinical staff demonstrate compliance

with current aseptic techniques when dispensing and

administering intravenous medications from vials and

ampules; and

The facility must have a mechanism in place to ensure expired

medications are not available for use. Opened multiple-dose vials

should be handled aseptically and used and discarded in accordance

with the manufacturer’s set time frames and/or other accepted

standards for use (e.g., US Pharmacopeia). Staff preparing

medications should clean the septum of any multi-use vial with

alcohol before inserting the needle and the injection port before using

Final Version 1.1 Page 29 of 299

TAG

NUMBER

REGULATION

INTERPRETIVE GUIDANCE

the port to administer a medication.

V144

(3) Require all clinical staff to report infection control

issues to the dialysis facility’s medical director (see §

494.150 of this part) and the quality improvement

committee.

There should be a documented reporting mechanism for infection

control issues. The nurse manager, administrator and medical director

should each be able to describe the infection control program and

reporting mechanisms.

Infection control and patient safety issues should be continuously

reported and discussed in QAPI meetings, and the response taken to

address these issues should be documented. Records of tracking

infections should be a part of the facility’s QAPI program. Refer to

V637.

V145

(c) Standard: Reporting. The facility must report

incidences of communicable diseases as required by

Federal, State, and local regulations.

The reporting of incidences of communicable diseases should be

documented and become a part of the QAPI record. Clusters of

adverse events should be promptly reported to the appropriate State or

local public health authority. The QAPI process does not preclude the

need to report serious adverse events to public health authorities in a

timely manner.

V146

(a)(2) The “Guidelines for the Prevention of

Intravascular Catheter-Related Infections” entitled

“Recommendations for Placement of Intravascular

Catheters in Adults and Children” parts I – IV; and

“Central Venous Catheters, Including PICCs,

Hemodialysis, and Pulmonary Artery Catheters in Adult

and Pediatric Patients,” Morbidity and Mortality Weekly

Report, volume 51 number RR-10, pages 16 through 18,

August 9, 2002. The Director of the Federal Register

approves this incorporation by reference in accordance

with 5 U.S.C. 552(a) and 1 CFR Part 51. This

publication is available for inspection as the CMS

Information Resource Center, 7500 Security Boulevard,

Central Building, Baltimore, MD or at the National

Archives and Records Administration (NARA). Copies

may be obtained at the CMS Information Resource

It is the intention of the Conditions for Coverage to incorporate

relevant guidance from the CDC “Guidelines for the Prevention of

Intravascular Catheter-Related Infections,” MMWR August 9,

2002/Vol. 51/No. RR-10 into the requirements for facility infection

control practices. Much of the material in this referenced guideline is

general or relates to catheter selection, insertion, and use in acute or

relatively short-term situations. The elements of this guidance which

are most on point for hemodialysis facilities address the risks posed

by intravascular catheters and the need for appropriate staff education,

surveillance, vascular access care, and rigorous hand hygiene in order

to reduce these risks.

For purposes of these Conditions for Coverage the portions of this

document which are incorporated by reference are mandatory and

must be adhered to and demonstrated within the dialysis facility.

Language incorporated from these documents has been edited for

Final Version 1.1 Page 30 of 299

TAG

NUMBER

REGULATION

INTERPRETIVE GUIDANCE

Center. For information on the availability of this

material at NARA, call 202–741–6030, or go to:

http://www.archives.gov/federal_register/code_of_regula