• T 704 529 5442 W pattonsmedical.com

Page 1

DOC# Manual_Signal1 Revision 11/1/2021

SIGNAL 1 with SYSTEM HEALTH

OPERATING INSTRUCTIONS

SIGNAL 1 with SYSTEM HEALTH

OPERATING INSTRUCTIONS

• Medical Air

• Lab Air

• Instrument Air

• Medical Vacuum

• Lab Vacuum

Signal 1

Operation and

Maintenance

Manual

• T 704 529 5442 W pattonsmedical.com

Page 2

DOC# Manual_Signal1 Revision 11/1/2021

SIGNAL 1 with SYSTEM HEALTH

OPERATING INSTRUCTIONS

Table of Contents

• Contact Information

• Safety Precautions

• Control Panel Front

• Main Display Screen

• Menu Screen

• System Health Screen

• System Health Parameter

Adjustment screen

• Alarm History

• Pressure/Vac Settings

• System Data

• Common Alarms

• Service Intervals

• Service

• Troubleshooting

• Ambient Temp Trend

• Amps Trend

• Pressure/Vac Trend

• # Pumps Running Trend

• Pump Cycle TrendDew Point

Trend

• CO Trend

• LAN Settings

• HMI Settings Tab (Time/Date

change)

• Warranty

• T 704 529 5442 W pattonsmedical.com

Page 3

DOC# Manual_Signal1 Revision 11/1/2021

SIGNAL 1 with SYSTEM HEALTH

OPERATING INSTRUCTIONS

ADDRESS:

Pattons Medical LLC

4610 Entrance Drive, Suite H

Charlotte, NC 28273

PHONE:

704-529-5442

Service: X10250

Parts: X10248 or X10310

WEBSITE:

www.pattonsmedical.com

• T 704 529 5442 W pattonsmedical.com

Page 4

DOC# Manual_Signal1 Revision 11/1/2021

SIGNAL 1 with SYSTEM HEALTH

OPERATING INSTRUCTIONS

Pressurized air and vacuum from the system may cause personnel injury or property damage

if the unit is improperly operated or maintained. The operator should have carefully read and

become familiar with the contents of this manual before installing, wiring, starting, operating,

adjusting, and maintaining the system. The operator is expected to use common sense safety

precautions, good workmanship practices and follow any related local safety precautions.

• Safety Precautions

In Addition:

• Before starting any installation or maintenance procedures, disconnect all power to the

package.

• All electrical procedures must be in compliance with all national, state, and local codes and

requirements.

• A certified electrician should connect all wiring

• Refer to the electrical wiring diagram provided with the unit before starting any installation or

maintenance work.

• Release all pressure/vacuum from the package before removing, loosening, or servicing

any covers, guards, fittings, connections, or other devices.

• Notify appropriate hospital personnel if repairs or maintenance will affect available

compressed air/vacuum levels.

• AIR: Air inlet must be placed in an area free of toxic or hazardous contaminants. It must be

kept away from ETO exhaust vents, vacuum exhaust vents, areas close to automotive

exhausts, etc., in accordance with the latest edition of NFPA 99.

• Prior to using the medical system, the facility must have a certifier perform all installation

test as specified in the latest edition of NFPA 99 and is responsible for ensuring that the

Air/Vacuum meets the minimum requirements as specified in the latest edition of NFPA 99.

• This is a high speed, rotating piece of machinery. Do not attempt to service any part while

machine is in operation.

• Do not operate unit without safety devices (belt guards, shields, screens, etc.) in place.

• Make sure that all loose articles, packing material, and tools are clear of the package.

• Check all safety devices periodically for proper operation.

• AIR: Never operate a compressor with its isolation (shutoff) valve closed or without its relief

valve in place. Damage to the compressor may occur.

• Check compressor/vacuum requirements to see if oil is necessary for operation.

• The “HAND” mode of operation should only be used for emergencies such as PLC

malfunction and should not be used for normal operation.

• Electrical service must be the same as specified on the control panel nameplate or damage

to the equipment may occur.

• Vibration during shipment and operation can loosen electrical terminals, fuse inserts, and

mechanical connections. Tighten as necessary.

• Refer to the electrical diagram provided with the unit before starting any installation or

performing any maintenance work.

• Do not operate on a voltage other than the voltage specified on the system nameplate.

• All customer wiring should be in compliance with the National Electrical Code and any other

applicable state or local codes.

• T 704 529 5442 W pattonsmedical.com

Page 5

DOC# Manual_Signal1 Revision 11/1/2021

SIGNAL 1 with SYSTEM HEALTH

OPERATING INSTRUCTIONS

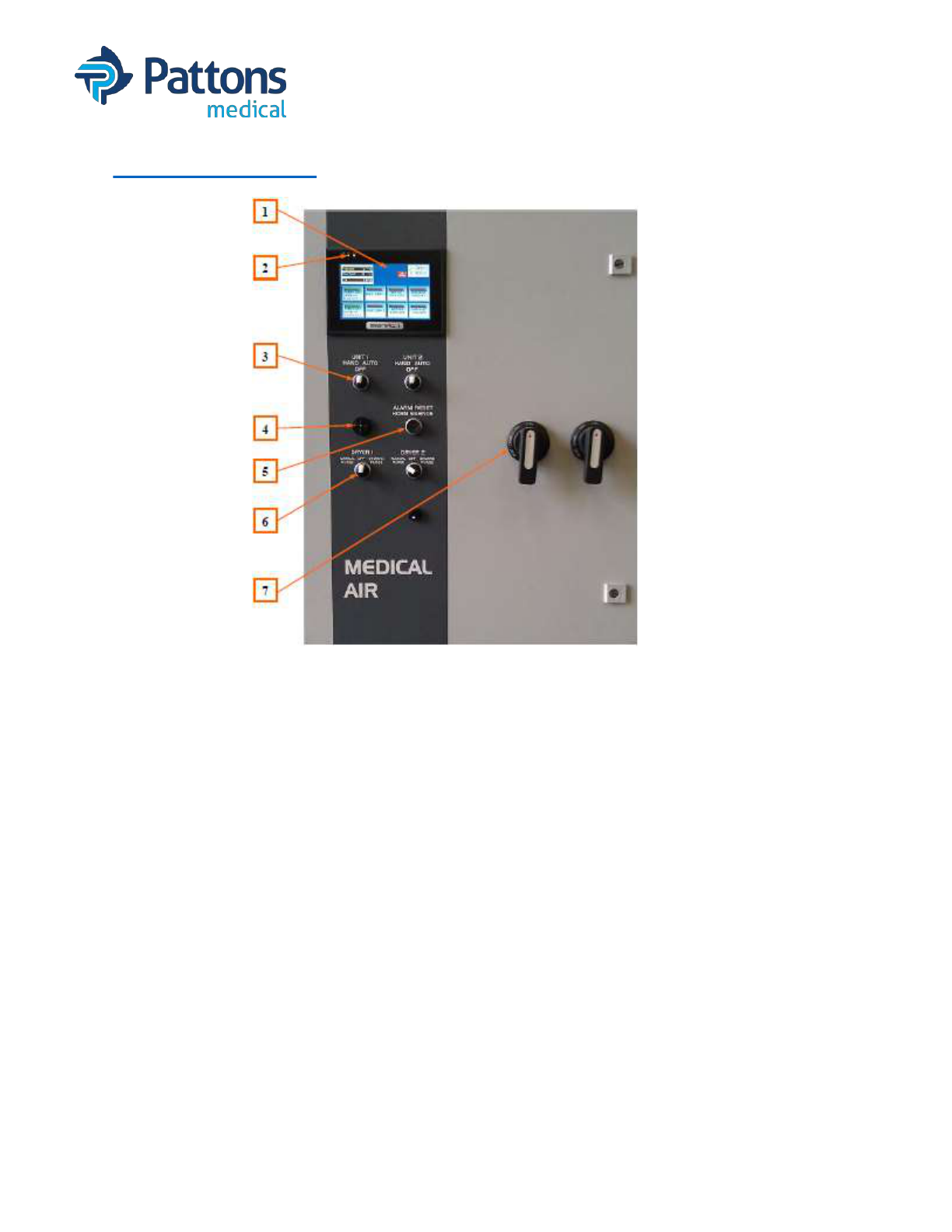

• Control Panel

1. Display Screen - Displays the systems operating screens.

2. LED’s – Yellow: Power is correctly supplied to the HMI Screen

3. HOA Selector Switch – Motor control switch, Hand – Off – Auto

4. Alarm Horn – Sounds when an alarm condition occurs

5. Alarm Reset/Horn Silence – Pushbutton to silence alarm and reset visual alarm on

Signal 1 screen after alarm condition is corrected

6. Dryer Control Selector Switch (Air) – Manual Purge – Off – Demand Purge

Purge Control Selector Switch (Vacuum) – Hand – Off – Auto Purge

7. External Operator – To control circuit breaker disconnect

• T 704 529 5442 W pattonsmedical.com

Page 6

DOC# Manual_Signal1 Revision 11/1/2021

SIGNAL 1 with SYSTEM HEALTH

OPERATING INSTRUCTIONS

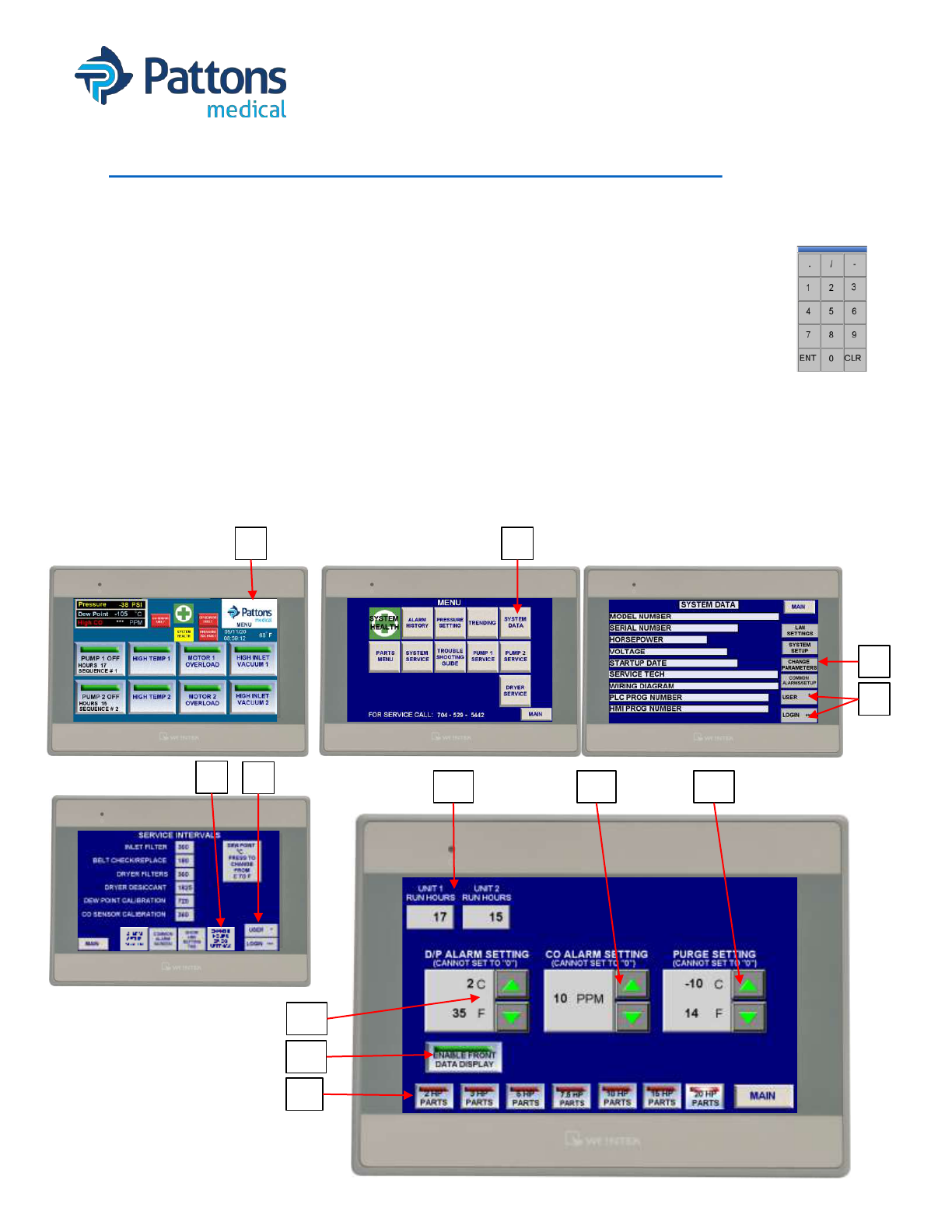

• Main Display Screen

At startup, you may get this screen. Touch the logo to proceed to the main screen.

95 PSI

-15 °C

CO 0 PPM

The main screen for systems will monitor and display the status of the system.

AIR: Receiver pressure, Dewpoint, CO, run sequence, hours, and current status of each module.

VACUUM: Receiver vacuum, run sequence, hours, and current status of each module.

Alarms for pressure/vacuum transducer fault, dewpoint sensor fault, CO sensor fault, PLC fault,

System Health warning, LAG Alarm, and service due also blink on this screen when activated.

Module alarms for high temperature, overload, and inlet vacuum (scroll only) will also blink when

Activated. Touching the icon of any alarm will take you to an informative screen.

The Menu screen in the upper right corner will allow you to navigate through multiple screens.

• T 704 529 5442 W pattonsmedical.com

Page 7

DOC# Manual_Signal1 Revision 11/1/2021

SIGNAL 1 with SYSTEM HEALTH

OPERATING INSTRUCTIONS

1. MENU: Displays menu screen which allows the operator to access the System Health

status, operating history, service requirements, trends, troubleshooting information,

pressure/vacuum settings, and system data information.

2. DEWPOINT (DP): Displays the current dew point reading at the units discharge point. If

the dew point reading is higher than 2°C, a high dew point alarm will occur. The dew point

indicatory will flash RED and the horn will sound. Pressing the RESET button on the

control panel front will silence the alarm. Touching the indicator while flashing red will open

a troubleshooting window. The dew point indicator will continue to flash red until the dew

point falls below 2°C. At this point, the dew point alarm will reset.

3. CARBON MONOXIDE (CO): Displays the current CO reading at the units discharge point.

If the CO reading is higher than 10 ppm, a high CO alarm will occur. The CO indicator will

flash RED and the horn will sound. Pressing the RESET button on the control panel front

will silence the alarm. Touching the indicator while flashing will open a troubleshooting

window. The CO indictator will continue to flash red until the CO falls below 10 ppm. At this

point, the CO alarm will reset.

4. PRESSURE (PSI): Displays the current pressure inside the receiver. Can change to BAR.

5. SERVICE DUE: Service intervals and types of service are pre-programmed into the Signal

1. The button will flash YELLOW when service is due. Pressing the “Service Due” button

when flashing will display the system or module 1 schedule screen. The item requiring

service will be flashing RED. If a module requires service, check module service screens.

6. PRESSURE/VACUUM TDC FAULT: Indicator will flash RED and horn will sound if the

transducer fails. Pressing the flashing red indicator will open the troubleshooting window.

7. DP SENSOR FAULT: Indicator will flash RED and horn will sound if the transducer fails.

Pressing the flashing red indicator will open the troubleshooting window.

8. CO SENSOR FAULT: Indicator will flash RED and horn will sound if the transducer fails.

Pressing the flashing red indicator will open the troubleshooting window.

95 PSI

-15 °C

CO 0 PPM

1

2

3

4

5

6

7

8

• T 704 529 5442 W pattonsmedical.com

Page 8

DOC# Manual_Signal1 Revision 11/1/2021

SIGNAL 1 with SYSTEM HEALTH

OPERATING INSTRUCTIONS

9. LAG ALARM: Indicator will flash RED and horn will sound when the last available module

comes on. Press the RESET button to silence the alarm. If the condition is corrected, both

the alarm and indicator will turn off. If the alarm condition remains, the indicating light on

the Signal 1 will remain on. Pressing the flashing red indicator will open the troubleshooting

window. Once the lag condition is corrected, press the reset button to turn off the indicator.

10.UNIT RUN HOURS: Displays total run hours for each module.

11.HAND-OFF-AUTO: Displays status of each module. The green “HAND” displays when

running and the HOA selector switch is in the HAND setting. The green “AUTO” displays

when is running and the HOA selector is in the AUTO position. The “OFF” indictor is

displayed when the HOA selector is in OFF position or module is not powered.

12.MOTOR OVERLOAD: Display will flash RED and sound an alarm when the overload switch

is tripped in the control panel. The module in question will not re-start until the RESET

button on the starter inside the control cabinet is reset. Press the reset button on the front

panel to silence the horn. Touching the indicator while flashing will open a troubleshooting

window. The indicator on the Signal 1 will remain on until the motor starter is reset.

13.HIGH TEMP: Display will flash RED and sound an alarm when the module is shut down

due to a high discharge air temperature. Press the reset button on the front panel to

silence/clear the alarm. The alarm cannot be cleared until the temperature drops below the

preset value. Touching the indicator while flashing will open a troubleshooting window.

14.INLET FAULT (Scroll only): Display will flash RED if the compressor inlet is restricted. Inlet

Fault will also cause a Failed to Start alarm. Pressing the RESET button will silence the

horn and clear the alarm. If the problem is not resolved, it will occur again.

15.SYSTEM HEALTH: The GREEN PLUS is the icon and will always take you directly to the

System Health screen. The yellow button when on will also take you to the same screen.

This screen provides and overview of the system and links to all trending screens.

95 PSI

-15 °C

CO 0 PPM

12

11

10

9

14

13

15

• T 704 529 5442 W pattonsmedical.com

Page 9

DOC# Manual_Signal1 Revision 11/1/2021

SIGNAL 1 with SYSTEM HEALTH

OPERATING INSTRUCTIONS

• MENU Screen

The menu screen provides a central gateway to access many additional screens of the Signal1.

1. SYSTEM HEALTH: This button takes you to the SYSTEM HEALTH screen that provides an

overview of the system and links to all trending screens.

2. ALARM HISTORY: Will open a new window listing all the alarm conditions that have

occurred as well as routine maintenance alerts and warnings. The list shows date and time

of the incident, type of incident, and when the incident was corrected/cleared. Alarms

shown on this screen have a permanent record.

3. PRESSURE/VACUUM SETTING: Shows current settings of the pressure or vacuum and a

button to return to factory default settings.

4. TRENDING: Goes directly to the SYSTEM HEALTH screen.

5. SYSTEM DATA: Provides all the system information required when scheduling maintenance

or purchasing spare parts from Patton Medical.

6. PARTS MENU: Provides a list of basic service parts for the system.

7. SYSTEM SERVICE: Takes you to the System Service screen. Other service screens also

take you directly to the individual module service screen or dryer service screen.

8. TROUBLESHOOTING GUIDE: Takes you to the troubleshooting screen which has links to

the individual troubleshooting guide pages.

9. MAIN: Can be found on most screens. Takes you back to the main screen.

1 2 3 4

5

8

6

7 9

• T 704 529 5442 W pattonsmedical.com

Page 10

DOC# Manual_Signal1 Revision 11/1/2021

SIGNAL 1 with SYSTEM HEALTH

OPERATING INSTRUCTIONS

• SYSTEM HEALTH (and Trending) Screen

The System Health screen provides an overall snapshot of the system status and allow warning

alarms to be set to provide notification that an alarm is pending.

1. AMBIENT TEMPERATURE: Provides temperature of room and notifies when above 105°F.

2. PRESSURE/VACUUM: Provides current reading and notifies at a predefined setpoint.

3. DEWPOINT: Displays current dewpoint and notifies at a predefined setpoint.

4. CO: Displays current CO reading and notifies at a predefined setpoint.

5. MOTOR: Displays output current when running. Does not show when run by VFD.

6. MAIN: Returns user to main screen.

7. MENU: Returns user to menu screen.

8. USER: Allows user to change System Health setpoints (1 then ENT).

9. LOGIN: All login so user can change System Health setpoints (307 then ENT).

10.HEALTH PARAMETER ADJUSTMENT: Hidden button to adjust System Health setpoints.

11.AMBIENT TEMP TREND: Goes to screen with ambient temperature charted.

12.AMPERAGE TREND: Goes to screen with amps charted for modules 1 & 2 with links to

additional modules if available.

13.PRESSURE/VACUUM TREND: Goes to screen with pressure/vacuum charted.

14.# PUMPS RUNNING TREND: Goes to screen that displays the number of modules running

at a defined interval.

15.PUMP CYCLE TREND: Trend screen of each module showing on and off cycles. Modules

1-5 shown on first page with link to another page to see 6-8 if applicable.

16.DEW POINT TREND: Link to trend screen of dew point showing the charted readings.

17.CO TREND: Link to trend screen of CO showing the charted readings.

LOW

PRESSURE

75

1 2

3

4

5

6

10

9

8

7

131211 14 15 16 17

• T 704 529 5442 W pattonsmedical.com

Page 11

DOC# Manual_Signal1 Revision 11/1/2021

SIGNAL 1 with SYSTEM HEALTH

OPERATING INSTRUCTIONS

• HEALTH PARAMETER ADJUSTMENT Screen

The System Health parameter adjustment screen allow the operator to make adjustments for

the warning to alarm. Since these are only warnings, they are not controlled by NFPA 99.

1. MAIN: Returns user to main screen.

2. CURRENT: Provides adjustment to the percentage above FLA allowed before a warning.

3. PRESSURE/VACUUM: Provides adjustment to the pressure/vacuum before a warning is

sent.

4. DEWPOINT (air only): Provides adjustment to when a dewpoint warning will alarm.

5. CO (air only): Provides adjustment to when a CO warning will alarm.

6. DEFAULT SETTINGS: Returns above settings to the Pattons Medical default value.

7. OVERLOAD SETTING: Shows the actual setting of the overload for each motor.

1. To adjust, turn dial setting on overload

2. On PLC, move Run switch to STOP, then return to RUN

3. Overload settings are re-read and are updated on the below screen.

4. Repeat above steps each time overload dial is adjusted.

1

2 3 4 5

6

7

• T 704 529 5442 W pattonsmedical.com

Page 12

DOC# Manual_Signal1 Revision 11/1/2021

SIGNAL 1 with SYSTEM HEALTH

OPERATING INSTRUCTIONS

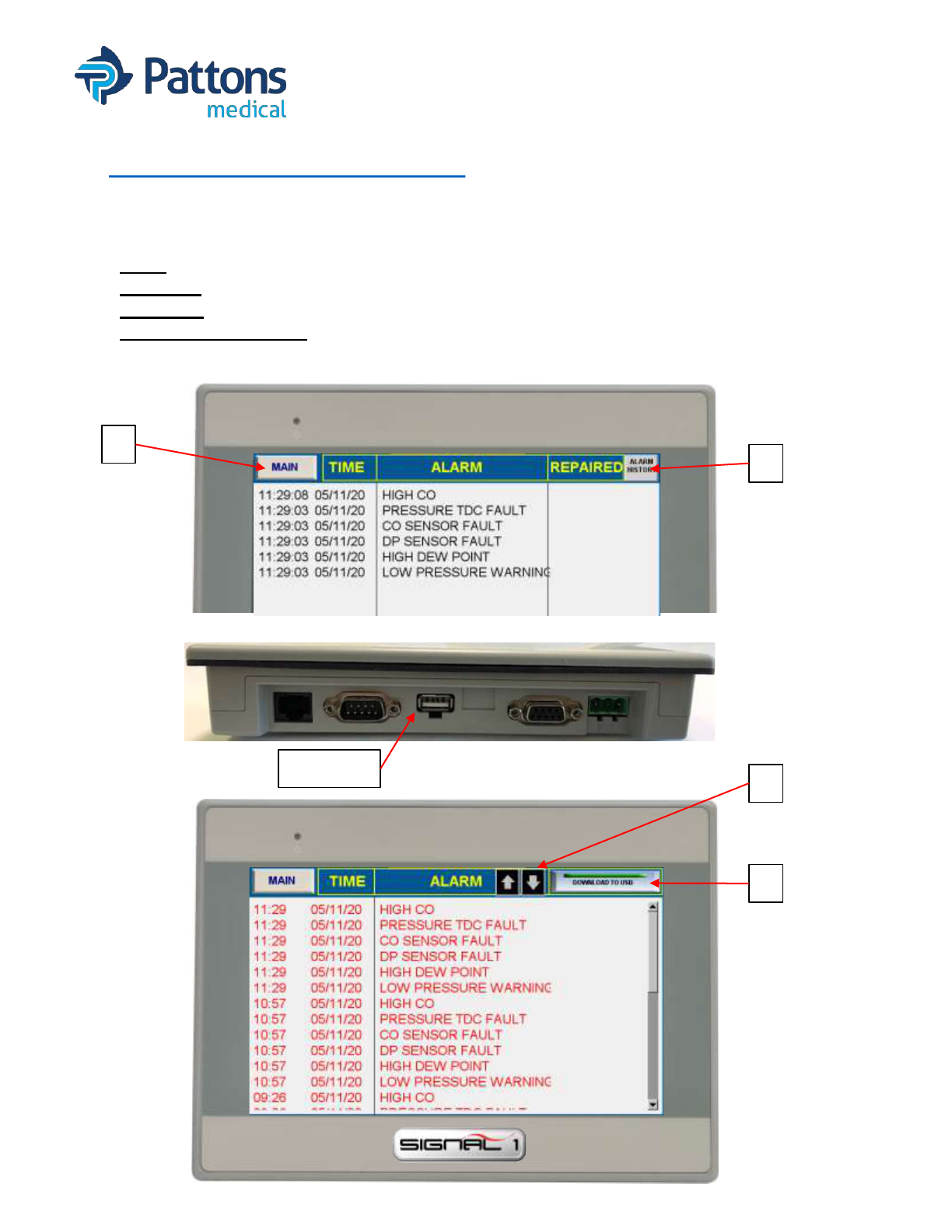

• ALARM HISTORY Screen

The Alarm History screen provides an overview off the last alarms that have been logged. It

provides the time and date the alarm triggered, the type of alarm, and the time the alarm was

repaired or cleared.

1. MAIN: Takes you back to the main screen.

2. HISTORY: Takes you to the Alarm History page.

3. ARROWS: Allows you to scroll thru days of alarms.

4. DOWNLOAD TO USB: Allows you to download all alarms to a USB memory device.

1

2

4

3

USB port

• T 704 529 5442 W pattonsmedical.com

Page 13

DOC# Manual_Signal1 Revision 11/1/2021

SIGNAL 1 with SYSTEM HEALTH

OPERATING INSTRUCTIONS

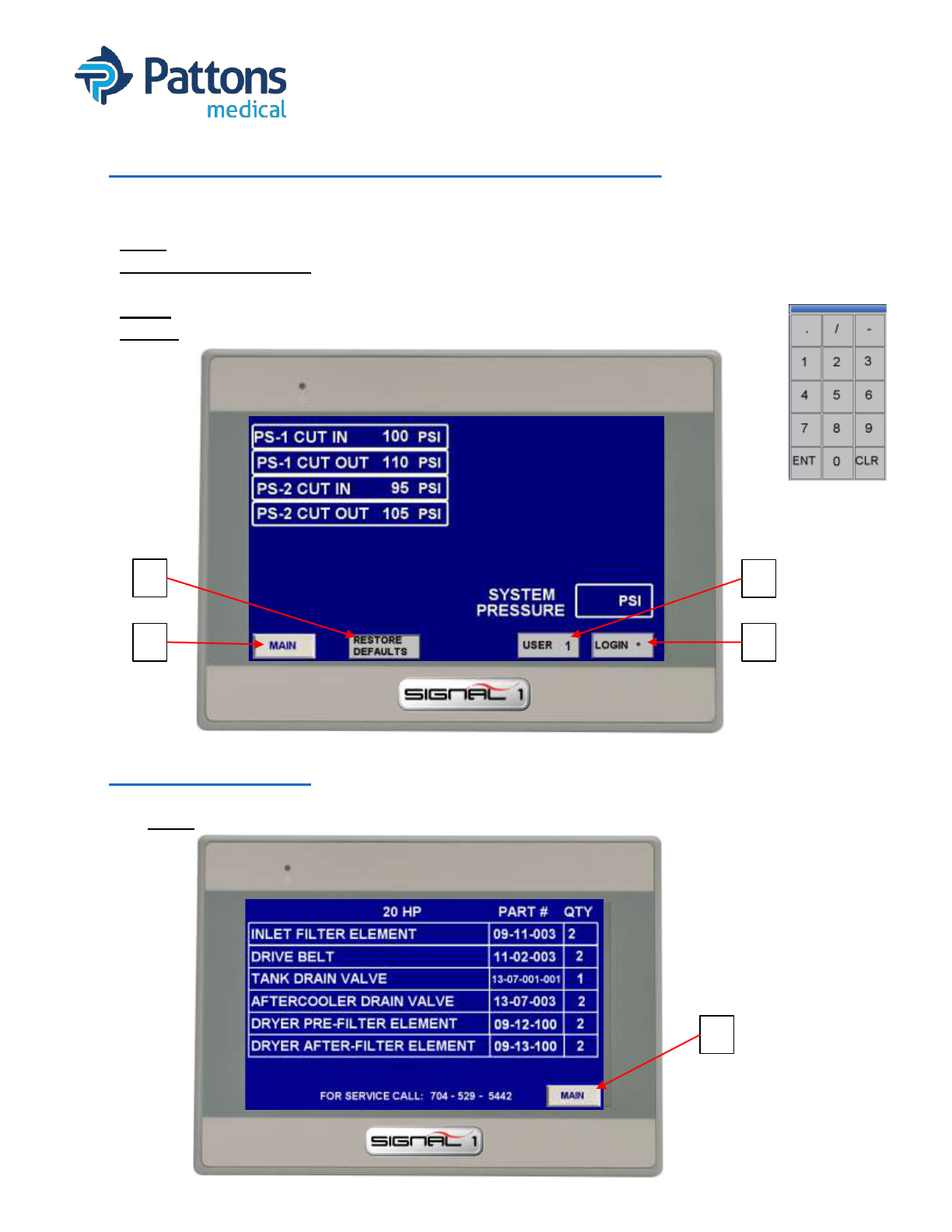

• PRESSURE/VACUUM SETTING Screen

The Pressure or Vacuum Setting screen allows you to customize the settings for the system.

It also allows you to return these values back to the default values.

1. MAIN: Takes you back to the main screen.

2. RESTORE DEFAULTS: Returns pressure/vacuum settings to factory default. The USER

and LOGIN must be entered to activate the button.

3. USER: Enter to be able to restore defaults (2 then ENT)

4. LOGIN: Enter to be able to restore defaults (327 then ENT)

102

1

2

3

4

• PARTS Screen

The Parts menu provides a list of common service item part numbers to the equipment.

1. MAIN: Takes you back to the main screen.

1

• T 704 529 5442 W pattonsmedical.com

Page 14

DOC# Manual_Signal1 Revision 11/1/2021

SIGNAL 1 with SYSTEM HEALTH

OPERATING INSTRUCTIONS

• SYSTEM DATA Screen

The System Data screen provides key information about the system that is helpful to the

service person and/or when calling for support.

1. MAIN: Takes you back to the main screen.

2. USER: Enter to be able to restore defaults (2 then ENT)

3. LOGIN: Enter to be able to make changes/access more menus (327 then ENT)

4. DATE and TIME: After login, touch the #’s and a pop-up screen will appear to change

5. COMMON ALARMS/SETUP: This button takes you to a screen that allows selection of

what conditions/alarms will activate the common alarm signal. This screen also allows the

user to select units and turn OFF horns for System Health warnings.

5. HIDDEN SERVICE BUTTONS: These buttons are for service and setup of the controller.

1. ACCESS: USER: 4; LOGIN: 396

2. LAN SETTINGS: To change the IP addresses for PLC interface and MODBUS data.

3. SYSTEM SETUP: For initial setup of HMI.

4. CHANGE PARAMETERS: To adjust the service intervals; change DP units; change

date and time

2

1

5

2

3

3

4

1

4

• T 704 529 5442 W pattonsmedical.com

Page 15

DOC# Manual_Signal1 Revision 11/1/2021

SIGNAL 1 with SYSTEM HEALTH

OPERATING INSTRUCTIONS

• COMMON ALARM Screen

The common alarm screen allows the operator to select which alarms will trigger the common

alarm output signal. When lighted, the alarm is activated to trigger the common alarm output.

*NOTE: Alarms are dependent on type of system. Not all alarms may be present on all systems.

1. MAIN: Takes you back to the main screen.

2. LAG ALARM: Alarms when the pump in reserve turns on. There is a separate alarm as well.

3. HIGH TEMP: Alarms when the high temperature switches close (discharge-air; exhaust-vac)

4. MOTOR OVERLOAD: Alarms when the overload relay trips. Must manually reset.

5. PUMP FAILED TO RUN: Alarms when the module does not start. Find reason and repair.

6. HIGH INLET FAULT (scroll only): Alarms when a vacuum is sensed at the inlet. The isolation

valve is closed or something is blocking the intake. Equipment protection fault.

7. HIGH DEW POINT: Alarms when high dewpoint sensed. There is a separate alarm as well.

8. DP SENSOR RECAL: Service alarm for when recalibration is due on the dewpoint sensor.

9. DRYER FILTERS DUE: Service alarm when particulate filters reach defined time limit.

10.DRYER DESICCANT DUE: Service alarm when desiccant reaches defined time limit.

11.SYSTEM HEALTH: Sends alarm signal when any system health reaches defined setting.

12.INLET FILTER DUE: Service alarm when inlet filters reach defined time limit.

13.CHECK BELT TENSION: Service alarm when belt reaches defined time limit.

14.500 HR TIP SEAL WARNING: Service alarm to notify the scroll pump is nearing rebuilt time.

15.TIP SEAL REPLACE DUE: Service alarm to notify the scroll pump needs to be rebuilt based

on a defined time limit.

16.HIGH CO: Alarms when high CO is sensed. There is a separate alarm as well.

17.CO SENSOR RECAL: Service alarm for when recalibration is due on the CO sensor.

18.SYSTEM UNITS: Allows the user to change the units for temperature and pressure readings.

19.SYSTEM HEALTH HORN SETUP: Allows the user to turn off horn alarms for system health

faults.

For standard vacuum systems, the RUN TIME selection is also available to select on this screen.

1

18

19

• T 704 529 5442 W pattonsmedical.com

Page 16

DOC# Manual_Signal1 Revision 11/1/2021

SIGNAL 1 with SYSTEM HEALTH

OPERATING INSTRUCTIONS

• SERVICE INTERVALS (Change Parameters) Screen

The Service Intervals screen allows the operator to adjust the standard service times of

serviceable items. The current setting is shown in the boxes beside the description.

1. MAIN: Takes you back to the main screen.

2. USER: Allows user to login and adjust settings on the screen (4 then ENT)

3. LOGIN: Allows user to login and adjust settings on the screen (396 then ENT)

4. DEW POINT CHANGE C to F (air only): Allows user to change dewpoint display between °C

and °F.

5. COMMON ALARM SCREEN: Take user to common alarm screen.

6. INLET FILTER: Standard replacement is 1/year.

7. BELT CHECK/REPLACE (air only): Standard check is every 6 months.

8. DRYER FILTERS (air only): Standard replacement is every 5 years.

9. DRYER DESICCANT (air only): Standard replacement is 1/year.

10.DEWPOINT CALIBRATION (air only): Standard calibration is every 2 years.

11.CO SENSOR CALIBRATION (air only): Standard calibration is 1/year.

12.OIL AND FILTER (vacuum only): Standard replacement is shown (varies based on type of

vacuum).

1

5

2

3

4

• T 704 529 5442 W pattonsmedical.com

Page 17

DOC# Manual_Signal1 Revision 11/1/2021

SIGNAL 1 with SYSTEM HEALTH

OPERATING INSTRUCTIONS

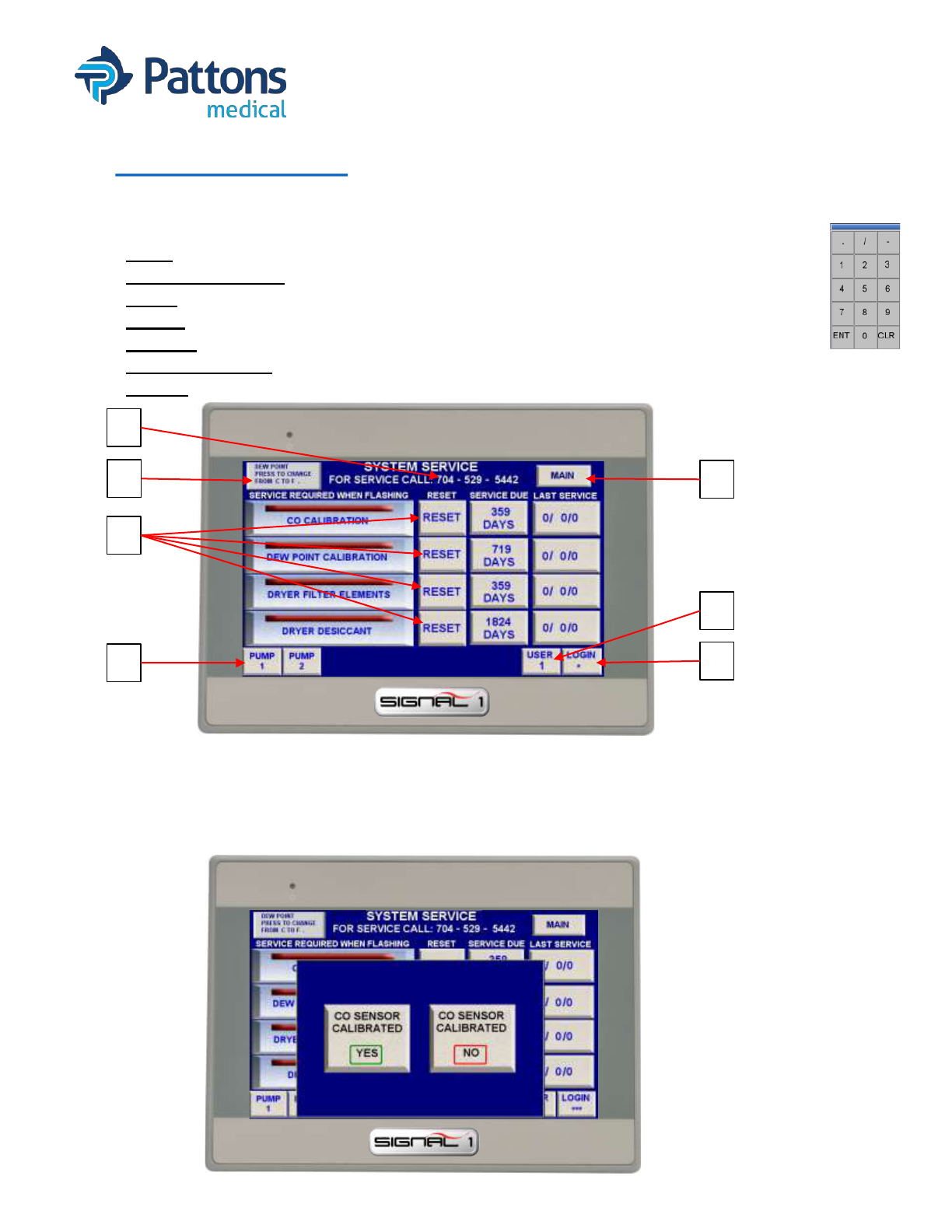

• SERVICE Screen

The Service screen provides information on when the service function was last performed and

how many days or hours until service is due again. When service is due, the tag on the left

will flash as notification and the Service Due button will be illuminated on the main page.

1. MAIN: Takes you back to the main screen.

2. DEWPOINT C to F: Allows user to change units for the dewpoint reading.

3. USER: Allows user to reset service time (4 then ENT)

4. LOGIN: Allows user to reset service time (396 then ENT)

5. PUMP X: Opens the service screen for a particular module.

6. Phone # Change: When logged in, the phone # can be touched and changed per section.

7. RESET: Records the date of reset and resets the hours/days until next service.

1

2

3

4

6

5

7

• RESET SCREEN (same layout for all service resets)

The reset screen allow the operator to reset the service performed. When selecting YES, the

date will be recorded and displayed and the service due timer will be reset to the set value.

Selecting NO will exit the screen and nothing is recorded.

• T 704 529 5442 W pattonsmedical.com

Page 18

DOC# Manual_Signal1 Revision 11/1/2021

SIGNAL 1 with SYSTEM HEALTH

OPERATING INSTRUCTIONS

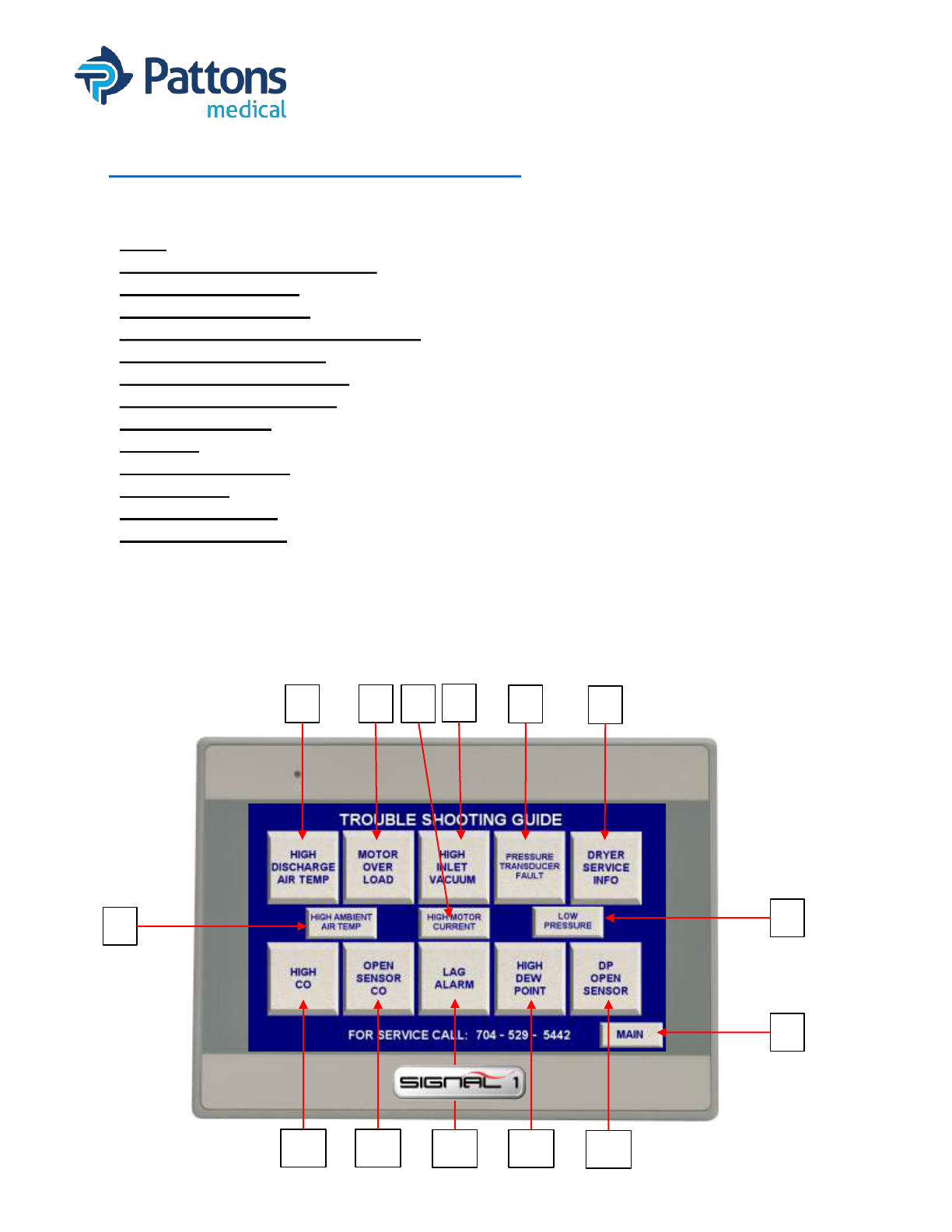

• TROUBLESHOOTING Screen

The Pressure or Vacuum Setting screen allows you to customize the settings for the system. It

also allows you to return these values back to the default values.

1. MAIN: Takes you back to the main screen.

2. HIGH DISCHARGE AIR TEMP: Opens a pop-up window with possible reasons for alarm.

3. MOTOR OVERLOAD: Opens a pop-up window with possible reasons for alarm.

4. HIGH INLET VACUUM (scroll only): Opens a pop-up window with possible reasons for alarm.

5. PRESSURE TRANSDUCER FAULT: Opens a pop-up window with possible reasons for fault.

6. DRYER SERVICE INFO (air only): Opens a pop-up window with possible reasons for alarm.

7. HIGH AMBIENT AIR TEMP: Opens a pop-up window with possible reasons for alarm.

8. HIGH MOTOR CURRENT: Opens a pop-up window with possible reasons for alarm.

9. LOW PRESSURE: Opens a pop-up window with possible reasons for alarm.

10.HIGH CO: Opens a pop-up window with possible reasons for alarm.

11.CO OPEN SENSOR: Opens a pop-up window with possible reasons for fault.

12.LAG ALARM: Opens a pop-up window with possible reasons for alarm.

13.HIGH DEW POINT: Opens a pop-up window with possible reasons for alarm.

14.DP OPEN SENSOR: Opens a pop-up window with possible reasons for fault.

32

1

6

5

4

7

9

8

1110

14

1312

• T 704 529 5442 W pattonsmedical.com

Page 19

DOC# Manual_Signal1 Revision 11/1/2021

SIGNAL 1 with SYSTEM HEALTH

OPERATING INSTRUCTIONS

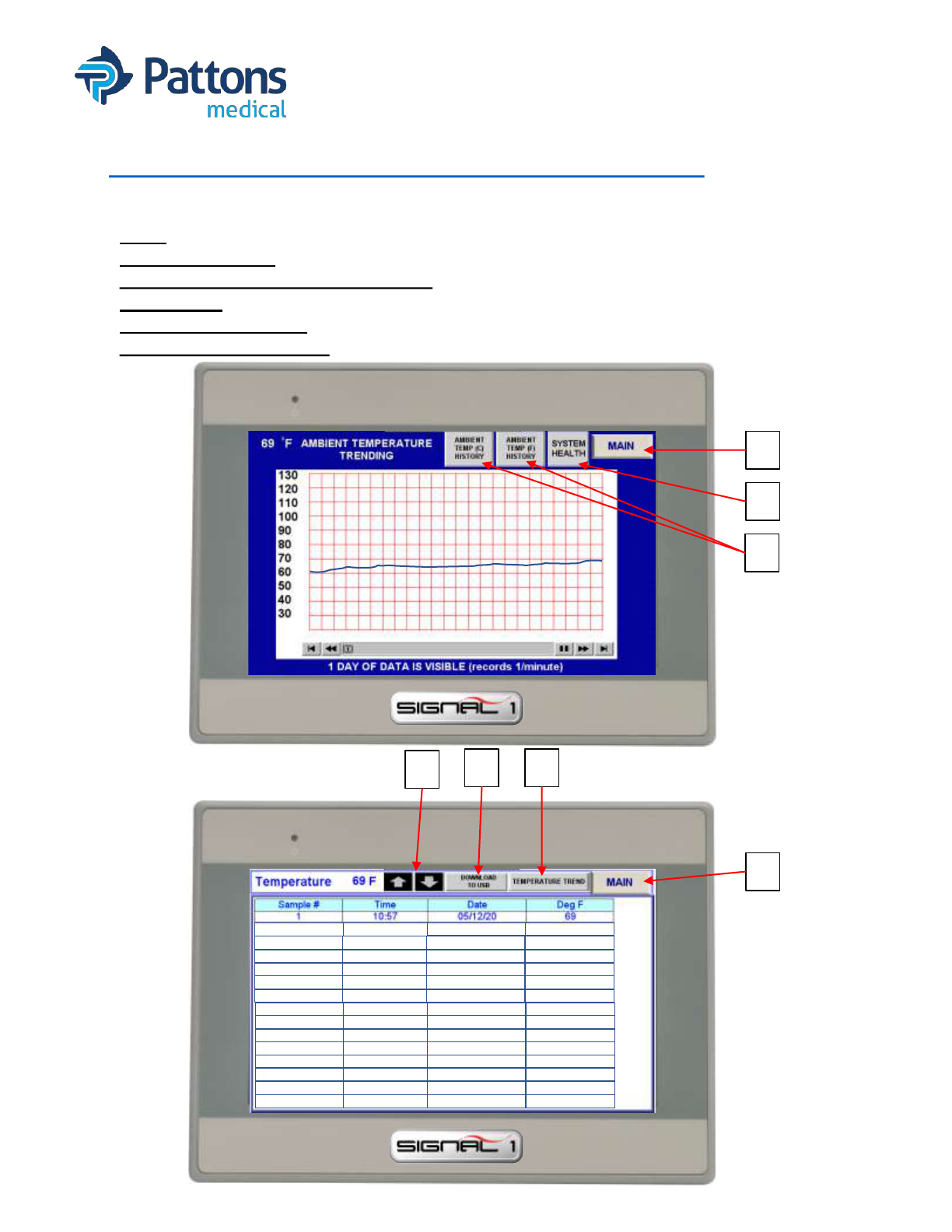

• AMBIENT TEMPERATURE TREND Screen

The ambient temp trend screen and data screens allow the operator to see the temperature

history to assist in correlating to any problems or issues that have been seen.

1. MAIN: Takes you back to the main screen.

2. SYSTEM HEALTH: Takes you back to the system health screen.

3. AMBIENT TEMP (F) or (C) HISTORY: Opens screen with readings in °F or °C for export.

4. “ARROWS”: Allows scrolling thru readings.

5. DOWNLOAD TO USB: Allows user to export data readings to USB drive.

6. TEMPERATURE TREND: Takes user back to Temperature trending graph page.

2 10:56

05/12/20

69

3 10:55

05/12/20

68

4 10:54

05/12/20

68

5 10:53

05/12/20

68

6 10:52

05/12/20

69

8 10:51

05/12/20

68

9 10:50

05/12/20

68

10 10:49

05/12/20

67

11 10:48

05/12/20

67

12 10:47

05/12/20

67

13 10:46

05/12/20

68

14 10:45

05/12/20

68

15 10:44

05/12/20

68

16 10:43

05/12/20

68

4

6

1

5

1

2

3

• T 704 529 5442 W pattonsmedical.com

Page 20

DOC# Manual_Signal1 Revision 11/1/2021

SIGNAL 1 with SYSTEM HEALTH

OPERATING INSTRUCTIONS

• AMPERAGE TREND Screen

The amperage trend screen allows the operator to see the graph and data points of the amps

being drawn by each motor to see if there is a trend that may foreshadow a problem.

1. MAIN: Takes you back to the main screen.

2. SYSTEM HEALTH: Takes you back to the system health screen.

3. MOTOR X DATA: Opens screen with amp readings for that motor for export.

4. “ARROWS”: Allows scrolling thru readings.

5. DOWNLOAD TO USB: Allows user to export data readings to USB drive.

6. CURRENT TREND: Takes user back to Amperage trending graph page.

4

6

1

5

1

2

3

• T 704 529 5442 W pattonsmedical.com

Page 21

DOC# Manual_Signal1 Revision 11/1/2021

SIGNAL 1 with SYSTEM HEALTH

OPERATING INSTRUCTIONS

• PRESSURE TREND Screen

The pressure trend screen allows the operator to view the graph and data points for the

pressure history and export the data if needed.

1. MAIN: Takes you back to the main screen.

2. MENU: Takes you back to the menu screen.

3. SYSTEM PSI or BAR HISTORY: Opens screen with readings for that motor for export.

4. “ARROWS”: Allows scrolling thru readings.

5. DOWNLOAD TO USB: Allows user to export data readings to USB drive.

6. PSI TREND: Takes user back to PSI trending graph page.

4

6

1

5

1

2

3

100

102

102

103

104

105

104

102

103

101

101

100

99

98

98

98

102

• T 704 529 5442 W pattonsmedical.com

Page 22

DOC# Manual_Signal1 Revision 11/1/2021

SIGNAL 1 with SYSTEM HEALTH

OPERATING INSTRUCTIONS

• # PUMPS RUNNING TREND Screen

The pumps running trend screen allows the operator to see how many pumps are running is

graph and data point form and export the data if needed.

1. MAIN: Takes you back to the main screen.

2. MENU: Takes you back to the menu screen.

3. PUMPS RUNNING HISTORY: Opens screen with readings for export.

4. “ARROWS”: Allows scrolling thru readings.

5. DOWNLOAD TO USB: Allows user to export data readings to USB drive.

6. PUMPS RUNNING: Takes user back to Pumps running trending graph page.

4

6

1

5

1

2

3

• T 704 529 5442 W pattonsmedical.com

Page 23

DOC# Manual_Signal1 Revision 11/1/2021

SIGNAL 1 with SYSTEM HEALTH

OPERATING INSTRUCTIONS

• PUMP CYCLE TREND Screen

The pumps cycle trend screen allows the operator to see when a pump is running and get

graph and data points and export the data if needed.

1. MAIN: Takes you back to the main screen.

2. SYSTEM HEALTH: Takes you back to the System Health screen.

3. MOTOR X DATA: Takes you to screen with data points for individual pumps.

4. “ARROWS”: Allows scrolling thru readings.

5. DOWNLOAD TO USB: Allows user to export data readings to USB drive.

6. CYCLE TREND: Takes user back to Cycle trending graph page.

4

6

1

5

1

2

3

• T 704 529 5442 W pattonsmedical.com

Page 24

DOC# Manual_Signal1 Revision 11/1/2021

SIGNAL 1 with SYSTEM HEALTH

OPERATING INSTRUCTIONS

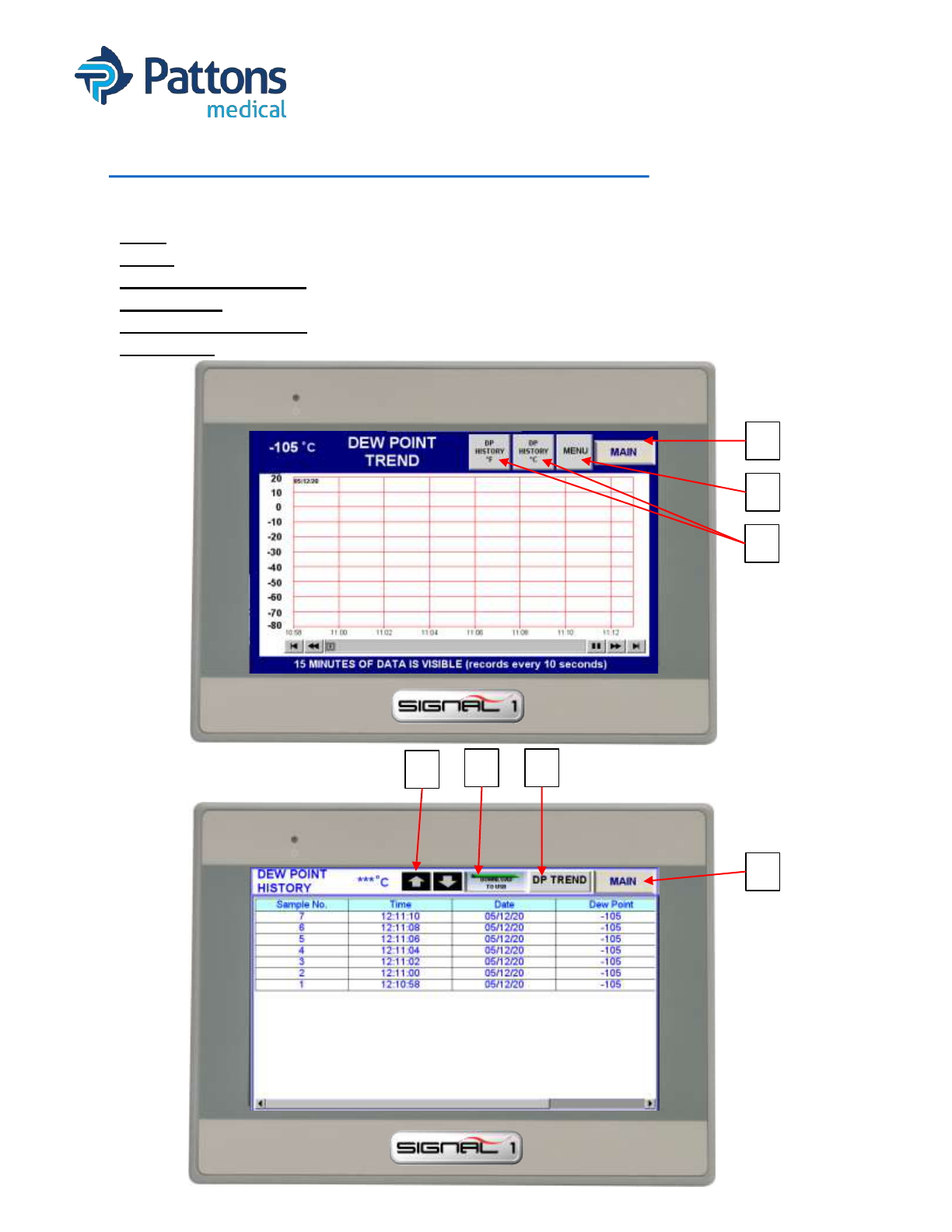

• DEW POINT TREND Screen (air only)

The dew point trend screen allows the operator to see the dew point and get graph and data

points and export the data if needed.

1. MAIN: Takes you back to the main screen.

2. MENU: Takes you back to the menu screen.

3. DP HISTORY °F or °C: Takes you to screen with data points for dewpoint in °F or °C.

4. “ARROWS”: Allows scrolling thru readings.

5. DOWNLOAD TO USB: Allows user to export data readings to USB drive.

6. DP TREND: Takes user back to Cycle trending graph page.

4

6

1

5

1

2

3

• T 704 529 5442 W pattonsmedical.com

Page 25

DOC# Manual_Signal1 Revision 11/1/2021

SIGNAL 1 with SYSTEM HEALTH

OPERATING INSTRUCTIONS

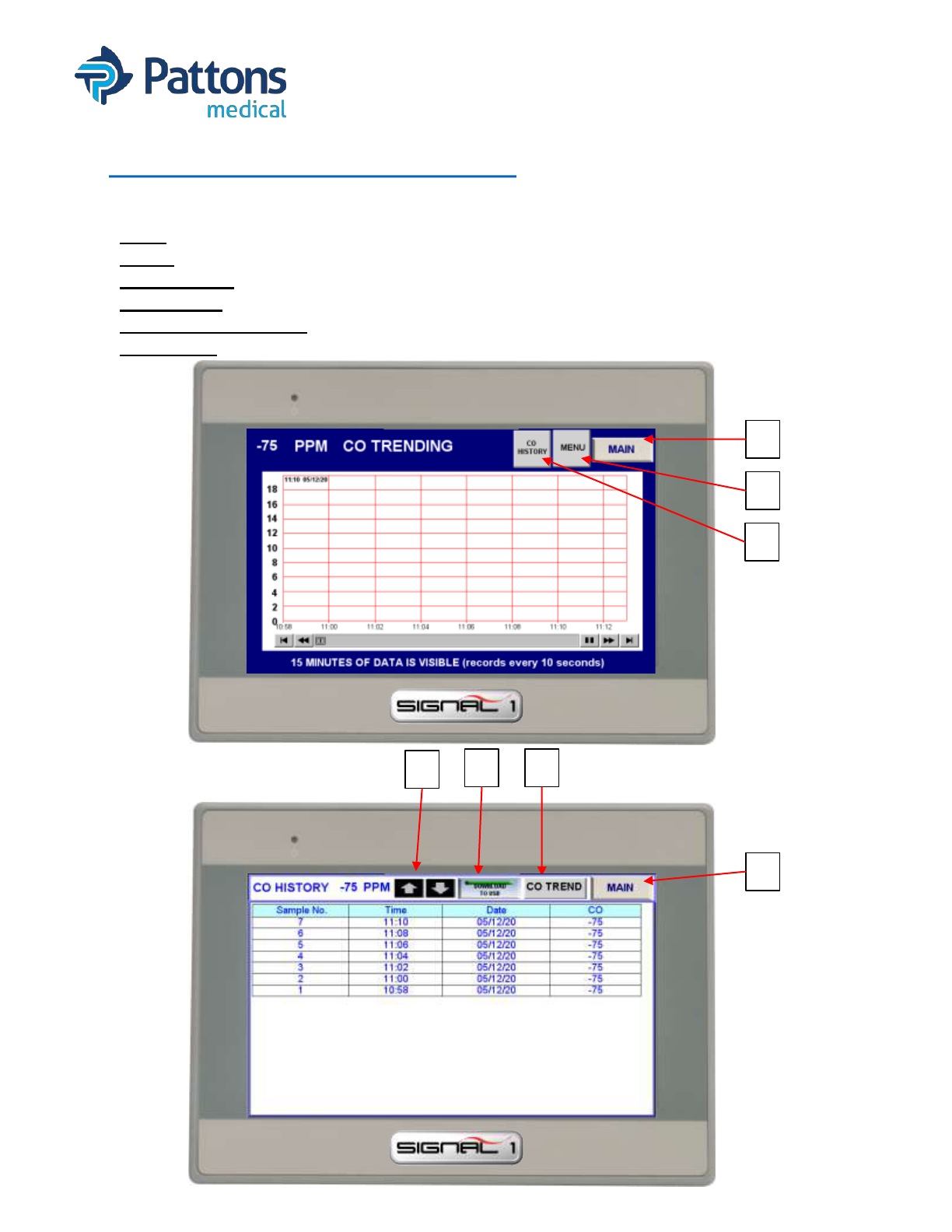

• CO TREND Screen (air only)

The dew point trend screen allows the operator to see the dew point and get graph and data

points and export the data if needed.

1. MAIN: Takes you back to the main screen.

2. MENU: Takes you back to the menu screen.

3. CO HISTORY: Takes you to screen with data points for CO.

4. “ARROWS”: Allows scrolling thru readings.

5. DOWNLOAD TO USB: Allows user to export data readings to USB drive.

6. CO TREND: Takes user back to Cycle trending graph page.

4

6

1

5

1

2

3

• T 704 529 5442 W pattonsmedical.com

Page 26

DOC# Manual_Signal1 Revision 11/1/2021

SIGNAL 1 with SYSTEM HEALTH

OPERATING INSTRUCTIONS

• LAN SETTINGS screen

The LAN settings screen allows the operator to change the IP address of the HMI, PLC, and

output MODBUS. Additional network parameters can also be changed.

1. MAIN: Takes you back to the main screen.

2. USER: Allows operator to log in to make changes (4 then ENT).

3. LOGIN: Allows operator to log in to make changes (396 then ENT).

4. PORT: Allows operator to change the port number of the HMI. Consult IT before changing.

5. LAN 1: IP address of the HMI. Consult IT before changing.

6. MAC 1: MAC address of HMI. Consult IT before changing.

7. SHOW LAN SETTING TAB: This brings up HMI login screen. Adjustments to IP address,

time, date, and other HMI settings can be made thru this login.

8. RESET: Press after in block after changing the IP address of the HMI, PLC, or Modbus.

9. PLC IP ADDRESS: Address where HMI is looking for PLC.

10.PLC PORT: Port location of PLC IP Address.

11.MODBUS IP ADDRESS: Address where HMI is sending MODBUS packets.

12.MODBUS PORT: Port location where Modbus packets are being sent.

13.MODBUS STATION No: Station number of Modbus device.

14.MODBUS OFF: Turns off Modbus output.

15.PLC IP ADDRESS: This function requires a special login. Contact Pattons Medical.

• Top address it he current PLC IP address

• Lower address is the new address to be saved. New address must be enter in HEX.

• i.e.: If IP address needs to be 192.168.1.20, the you would enter

1

st

block: C0A8 and 2

nd

block: 0114

16.ALT IP USAGE: Select this button to make the new PLC IP address active in the PLC.

Then the PLC and HMI must be rebooted.

15

16

HEX entry

1

6

5

8

2

3

4

87

9

10

11

12

14

13

• T 704 529 5442 W pattonsmedical.com

Page 27

DOC# Manual_Signal1 Revision 11/1/2021

SIGNAL 1 with SYSTEM HEALTH

OPERATING INSTRUCTIONS

• HMI SETTING TAB

The HMI Setting tab allow the operator to make changes to HMI parameters. The 2 most

common changes are 1) IP address and 2) date and time. There are several others too.

1. Go to MENU screen

2. Select SYSTEM DATA tab

3. Enter USER 4, then ENT

4. Enter LOGIN 396, then ENT

5. Select CHANGE PARAMETERS button

6. Enter USER 4; LOGIN 396

7. Select SHOW HMI SETTING TAB

8. A pop-up KEYBOARD will appear, then a PASSWORD pop-up screen.

9. Once PASSWORD screen appears, enter 111111 for password and hit OK (may auto exit)

10.SYSTEM SETTINGS pop-up screen will appear.

11.At this point, changes can be made to any system setting. Select APPLY to save. Select

OK or CANCEL to exit.

1 2

4

5

3

6 7 9 8

10

IP

addr

Date

Time

• T 704 529 5442 W pattonsmedical.com

Page 28

DOC# Manual_Signal1 Revision 11/1/2021

SIGNAL 1 with SYSTEM HEALTH

OPERATING INSTRUCTIONS

• CHANGE HOURS DP/CO SETTINGS screen

This screen has several adjustments that can be made for specific reasons by service only.

• Allows the service person to adjust the hours on each pump when PLC replaced.

• Allows the service person to adjust the DP, CO, and purge settings. The DP and CO are

default set to the NFPA 99 requirements. Purge is set to avoid a DP alarm.

1. Menu

2. System Data (User 4; Login 396)

3. Change Parameters (Login for Trained Service Personnel ONLY)

4. Change Hours DP/CO Settings

5. Once you have reached this screen, the

a) HOURS of each module can be changed (should only be done if PLC replaced)

b) DP ALARM SETTING can be changed (2°C is NFPA alarm setting)

c) CO ALARM SETTING can be changed (10 PPM is NFPA alarm setting)

d) PURGE SETTING can be changed

e) Front additional data can be displayed (mostly for VNC connection)

f) Parts list can be selected

1 2

3

2

3

5a

4

5e

5d5c

5b

5f

• T 704 529 5442 W pattonsmedical.com

Page 29

DOC# Manual_Signal1 Revision 11/1/2021

SIGNAL 1 with SYSTEM HEALTH

OPERATING INSTRUCTIONS

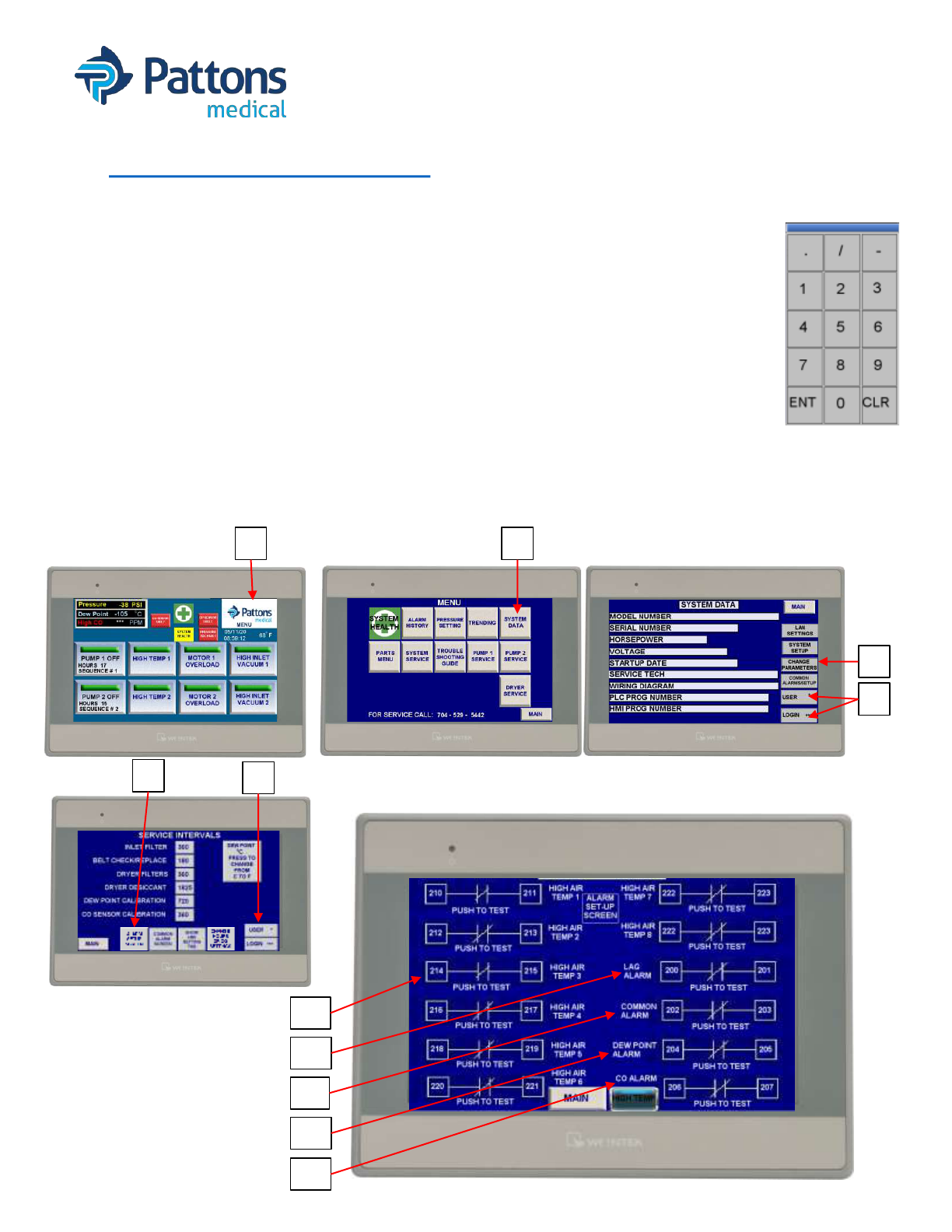

• ALARM SETUP screen

This screen allows the service person and certifier to trigger alarms for testing the system.

1. Menu

2. System Data (User 4; Login 396)

3. Change Parameters (Login for Trained Service Personnel ONLY)

4. Alarm Setup Screen

5. Once you have reached this screen, the

a) HIGH AIR TEMP for each module can be selected to see how to test

b) LAG ALARM can be triggered for test

c) COMMON ALARM can be triggered for test

d) DEW POINT ALARM can be triggered for test

e) CO ALARM can be triggered for test

1 2

3

2

3

4

5a

5b

5c

5d

5e

• T 704 529 5442 W pattonsmedical.com

Page 30

DOC# Manual_Signal1 Revision 11/1/2021

SIGNAL 1 with SYSTEM HEALTH

OPERATING INSTRUCTIONS

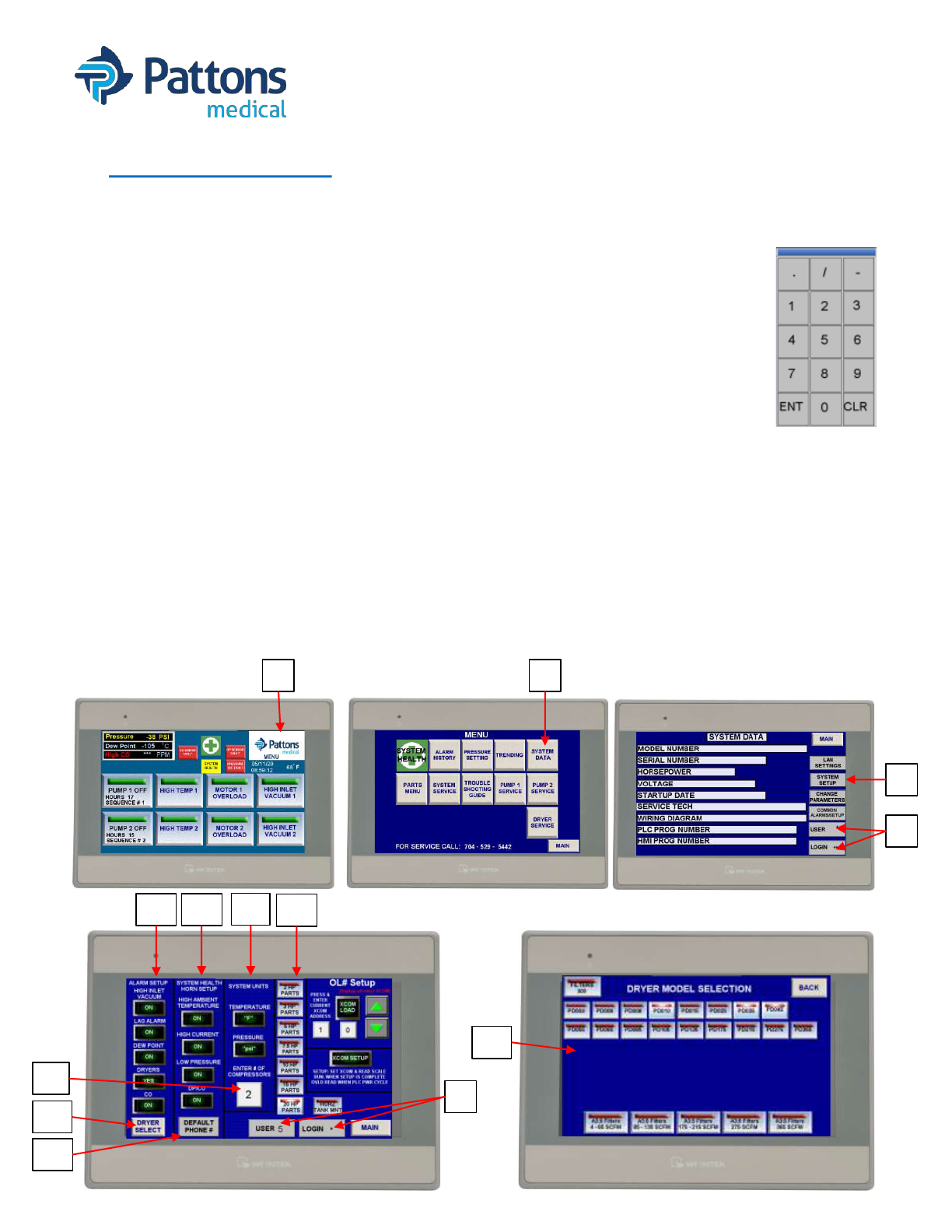

• SYSTEM SETUP

The HMI is designed to be modular with lots of options that can be turned OFF if not wanted.

This screen allows the assembler or service person to customize each unit to exactly what the

customer needs. This screen also allows for the setup of parts list, quantities, and setup of the

XCOM module in the overloads to read amps.

1. Menu

2. System Data (Login for Trained Service Personnel ONLY)

3. System Setup (Login for Trained Service Personnel ONLY)

4. Once you have reached this screen, there are multiple sections to review.

a) ALARM SETUP:

• HIGH INLET VACUUM (scroll only): ON if remote intake piping.

• LAG ALARM: ON for Medical; optional for all other applications

• DEW POINT: OFF if no dew point sensor installed on package

• DRYERS: OFF if no dryers installed on package

• CO: OFF if no CO sensor is installed on package

b) SYSTEM HEALTH HORN SETUP: horn alarms can be individually turned off

c) SYSTEM UNITS: can select units for temperature and pressure/vacuum

d) PARTS: select which parts list to show; may be extra selection for some models

e) DEFAULT PHONE #: enters the default Pattons Medical phone # on screens

f) ENTER # OF COMPRESSORS: defines quantities of parts for package & unit setup

g) DRYER SELECT: allows assembler to select dryers installed so service parts info is

correct on the parts screen. Many options due to pressure, Lag, other.

1 2

3

2

3

4a 4b

4c

4d

4g

4e

4f

4g

• T 704 529 5442 W pattonsmedical.com

Page 31

DOC# Manual_Signal1 Revision 11/1/2021

SIGNAL 1 with SYSTEM HEALTH

OPERATING INSTRUCTIONS

• SYSTEM SETUP (continued)

One of the features of System Health is the reading of amps thru the overload. The overloads

ID number has to be set-up when installed. All ID’s are 1 by default. If the overload and

XCOM are replaced, the address will have to be setup with this procedure.

1. Login on this screen: Login for Trained Service Personnel ONLY

2. Turn OFF XCOM RUN to XCOM SETUP.

3. Current address should be 1 (and this is default in the box on left)

4. Use “arrows” to define the number of the newly installed XCOM/overload (module 4 is #4)

5. Unplug all cables from XCOM modules except one being programmed.

6. Press XCOM LOAD button; button should light up, then turn OFF; this means a good write

7. Plug up all XCOM cables

8. Reboot PLC, HMI, and XCOMS (pull F15)

9. To check if working, the RS-485 RD & SD lights should be solid or very fast blink. If PLC

ERROR light comes ON and lights are not solid, then there is a communication/read error.

1

2

3 46

9 (RD/SD)

9 (ERROR)

• T 704 529 5442 W pattonsmedical.com

Page 32

DOC# Manual_Signal1 Revision 11/1/2021

SIGNAL 1 with SYSTEM HEALTH

OPERATING INSTRUCTIONS

• WRITE PLC PROGRAM from SDHC CARD

To update the PLC program, you will need a

• blank SDHC card

• laptop (or computer) with an SDHC card slot

• Program on computer to unzip the emailed program file

1. Save zipped PLC program to computer

2. Unzip the file and save the folder of files ($MELPRJ$) to the SDHC card

3. Notify appropriate people that Source Equipment alarms at the Master panel are going to

alarm

4. Turn enough pumps to HAND to handle the load

5. Turn PLC switch to STOP (middle) position

6. Install SDHC card into SD card slot on PLC

7. Push down and hold (3 seconds) STOP switch in RESET position (this loads new program)

• CARD LED will blink a few times and then go solid (when blinking, it is loading program)

6. Wait 30 seconds, then push and hold SD CARD OFF button until CARD light if OFF

7. When CARD light is off, push SD card in to EJECT (remove card)

8. Push down STOP switch again for 3 seconds to RESET the system

9. Then push up STOP switch to RUN position to start PLC.

10.Verify all alarms are correct and that PLC issue is not corrected

11.If good, notify appropriate people that you are done with source equipment repair.

5 (CARD LED)

4 (SDHC CARD slot)

6 (SD CARD OFF)

3/5/8/9 (STOP switch)

• T 704 529 5442 W pattonsmedical.com

Page 33

DOC# Manual_Signal1 Revision 11/1/2021

SIGNAL 1 with SYSTEM HEALTH

OPERATING INSTRUCTIONS

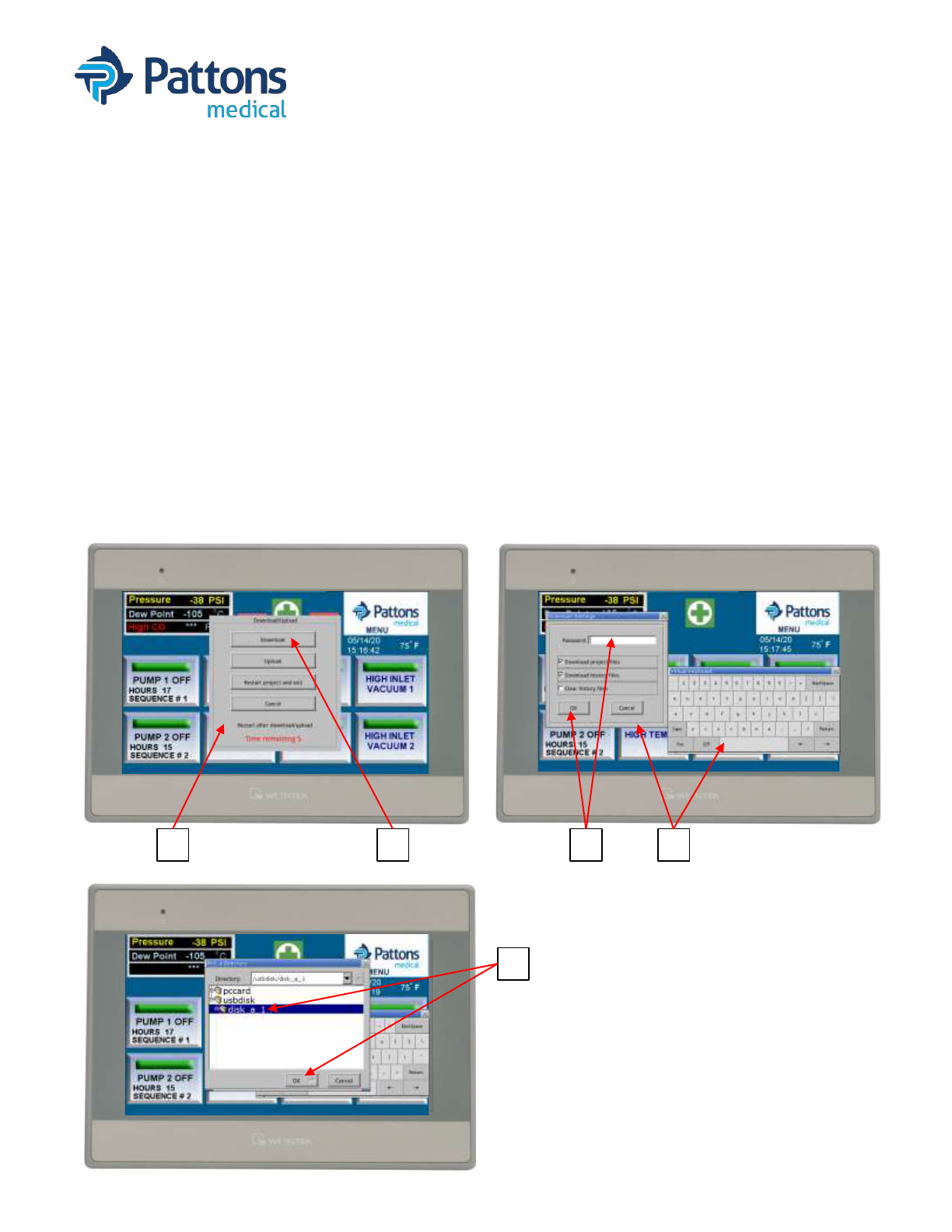

• WRITE HMI PROGRAM from USB stick

To update the USB program, you will need a

• blank USB memory stick

• laptop (or computer) with an USB connection

• Program on computer to unzip the emailed program file

1. Save zipped HMI program to computer

2. Unzip the file and save the folder of files (mt8000ie) to the USB stick

3. Install USB stick into USB slot on back bottom side of HMI

4. DOWNLOAD screen will appear on the HMI

5. Press the DOWNLOAD button on the screen

6. A keyboard and Password screen will appear

7. Enter 111111 (6x 1’s) and press OK (may auto OK)

8. Select usbdisk, then select/highlight “disk_a_1”

9. Press OK and program will start to download

10.When the initial screen reappears, the USB drive can be removed

4 5 67

8

• T 704 529 5442 W pattonsmedical.com

Page 34

DOC# Manual_Signal1 Revision 11/1/2021

SIGNAL 1 with SYSTEM HEALTH

OPERATING INSTRUCTIONS

• Warranty

Patton’s Medical Systems Warranty

Patton’s Medical warrants that all systems to be free of defects in material and workmanship under normal use for a

period of twenty-four months from start-up, not to exceed thirty months from date of shipment. This warranty covers

all necessary parts used in repair as well as all reasonable labor expense. Normal consumable parts required for

routine scheduled maintenance (such as filters) are not covered under this warranty.

This warranty does not apply to products that are damaged by external causes, or are improperly warehoused, used,

installed, serviced, misapplied or maintained by the customer. The sole liability for Patton’s Medical under this

warranty is limited to repairing, replacing, or crediting, at its election, any such products provided t hat:

• Patton’s Medical is notified promptly wit hin the warranty period above of any warranty claim.

• The exa mination of such items by an authorized representative of Patton’s Medical will disclose to their

reasonable satisfaction that claimed products defect has not been caused by misuse, neglect, improper handling,

installation, repair, alteration, or accidents.

• Patton’s Medical requires that systems above 5 Hp simplex be commissioned by an authorized Patton’s

Medical distributor and requires a start-up report to be filed within 30 days of equipment start-up. Failure to

submit a start-up repor t to Patton’s Medical will void the warranty.

• Replacement Parts including pumps and motors carry a limited warranty based upon manufacturer specific

terms. Parts carry a 90 day warranty unless the manufacturer’s stated warranty is different. Labor for these

warranties is not included or implied and is at the sole discretion of Patton’s Medical.

• Retrofit Control Panels carry a 12 month warranty from date of shipment.

• Simplex units 5Hp and below as well as r etrofit dryer packages do not include factory assisted start-up in t heir

base price unless specifically noted otherwise.

• Extended warranty is offered and will be noted in the quote.

Product modification performed by the customer without prior written approval by Patton’s Medical will invalidate

the above warranty.

This warranty is given in lieu of all other warranties, expressed or implied, including implied warranties of

fitness for a particular purpose and merchantability. In no event shall Patton’s Medical be liable for damages

in excess of the value of the defective product or part, nor shall Patton’s Medical be liable for any indirect,

special or consequential damages, loss of profits of any kind, or for loss of use of the products.

Patton’s Medical shall not be liable to the customer for any claims, loss of damage of any kind whatsoever arising

from the nonperformance of Patton’s Medical of any part of this agreement occasioned by acts of God, fire, war,

labor difficulties, governmental regulations, or action of government. Patton’s Medical shall not be liable to the

customer for any other cause, whether of a similar or dissimilar nature beyond its reasonable control.

• T 704 529 5442 W pattonsmedical.com

Page 35

DOC# Manual_Signal1 Revision 11/1/2021

SIGNAL 1 with SYSTEM HEALTH

OPERATING INSTRUCTIONS

4610 Entrance Drive, Suite H

Charlotte, NC 28273

704-529-5442

www.pattonsmedical.com