1.7.1

Engineered Plank & Strip Glued, Staple/Nail Down or Floating Installation

ENGINEERED PLANK & STRIP

GLUED OR STAPLE/

NAIL DOWN INSTALLATION

Mohawk Engineered Planks and Strips can be installed over most sub-floors, and are engineered to be

dimensionally stable, making them suitable for installation over all grade levels. See information and

installation guidelines below.

Attention – Installer/Owner Responsibility. Inspect ALL materials carefully BEFORE

installation. Wood is a natural product containing variations in color, tone and graining. Some

variation in color is to be expected in a natural wood floor. Even though our product goes

through many inspections before it leaves the plant, it is the customer’s and installer’s

responsibilities for final inspection prior to installation. Mohawk Hardwood Flooring warranties

DO NOT cover materials with visible defects once they are installed.

Tools

Basic tools and accessories: broom or vacuum, chalk line, tapping block, Mohawk’s cleaner, hand or electric

jamb saw, mitre saw, moisture meter, safety glasses, straight edge, table saw, tape measure, 3M blue tape,

square, utility knife, pry bar. Use Mohawk urethane wood flooring adhesive, towels and trowel if gluing or

a Bostitch Floor Runner (S3297-LHFZ) with 1” staple (SB97) or a 50C Power Nailer for nailing with a 1

1/2” power cleat. (Note: you must use a 3/8” or 1/2” adapter as appropriate.)

✔ Caution: Improper use of the Power Nailer can mark the surface of the flooring.

Job Conditions

It is the responsibility of the installer/owner to determine if the job site sub-floor and job site conditions are

environmentally and structurally acceptable for wood floor installation. Mohawk Hardwood Flooring

declines any responsibility for wood failure resulting from or connected with sub-floor, subsurface, job site

damage or deficiencies after hardwood flooring has been installed.

SUB-FLOOR PREPARATION AND

RECOMMENDATIONS FOR ALL INSTALLATIONS

Concrete Sub-floors

New concrete slabs require a minimum of 60 days drying time before covering them with a wood floor.

Light-weight Concrete

Light-weight concrete that has a dry density of 100 pounds or less per cubic foot is not suitable for Mohawk

wood floors. Many products have been developed as self-leveling toppings or floor underlayments. These

include cellular concrete, resin-reinforced cementious underlayments, and gypsum based materials. Although

1.7.2 Mohawk Hardwood Installation Guide

some of these products may have the necessary qualifications of underlayment for wood flooring installations,

others do not.

To test for lightweight concrete, scrape a coin or key across the surface of the subfloor. If the surface

powders easily or has a dry density of 100 pounds or less per cubic foot, do not install Mohawk hardwood.

Concrete sub-floors must be dry, smooth (level with 3/16” in a 10 foot radius – 1/8” in 6”) and free of

structural defects. Hand scrape or sand with a 20 grit #3 _ open face paper to remove loose, flaky concrete.

Grind high spots in concrete and fill low spots with a Portland based leveling compound (minimum 3000

PSI). Concrete must be free of paint, oil, existing adhesives, wax, grease, dirt and curing compounds.

These may be removed chemically or mechanically, but do not use solvent based strippers under any

circumstances. The use of residual solvents can prohibit the satisfactory bond of flooring adhesives. It is

important to ensure a proper bond between the adhesive and the concrete, and planks or strips. Mohawk

Engineered Hardwood Flooring may be installed on grade, above grade, as well as below grade where

moisture conditions do not exist.

➡ To ensure a long lasting bond, make sure that the perimeter of the foundation has adequate drainage

and vapor barriers.

Wood Sub-Floors

Wood sub-floors need to be well nailed or secured with screws. Nails should be ring shanks and screws

need to be counter sunk. The wood subfloor needs to be structurally sound and dry. They should not

exceed 14% moisture prior to installation. If the sub-floor is single layer, less than 3/4” thick, add a single

cross layer for strength and stability (minimum 5/16” thick for a total 1” thickness). This is to reduce the

possibility of squeaking. Wood sub-floors must be free of paint, oil, existing adhesives, wax, grease, dirt

and urethane, varnish etc. Underlayment grade OSB (not the wax side) is also a suitable sub-floor.

Particleboard is not an acceptable sub-floor for staple or nail down installations but can be used as a sub-

floor in glue down installations. When installing over existing wood flooring, install at right angles to the

existing floor.

Sub-Floor Moisture Check

Mohawk Hardwood Flooring Adhesive may be used for above, on and below grade applications and on all

common substrates. On and below grade applications are susceptible to moisture and should be tested for

moisture prior to installation in several locations within the installation area. Acceptable conditions for an

above, on and below grade applications are:

✔ Less than 3 lbs./1000 sq. ft./24 hrs. on a calcium chloride test.

✔ Less than a reading of 5.0 on a Tramex Concrete Moisture Encounter (moisture meter).

✔ Wood substrates must have a moisture reading of less than 14% when using a Tramex or Delmhorst

or equivalent moisture meter.

To correct any subfloor problems concerning moisture, either wait until the subfloor dries to meet

specifications or use and appropriate moisture barrier. For more information concerning moisture conditions,

call Mohawk’s Technical Department at 1-888-6MOHAWK (1-888-666-4295).

Sub-Floors Other than Wood or Concrete

➡ Note: Perimeter glued resilient vinyl and rubber tiles are unacceptable underlayments and must be

removed.

Terrazzo, tile and any other hard surfaces that are dry, structurally sound and level, as described above, are

1.7.3

Engineered Plank & Strip Glued, Staple/Nail Down or Floating Installation

suitable as a sub-floor for Mohawk Engineered Hardwood flooring installation. As above, the surface

must be sound, tight and free of paint, oil, existing adhesives, wax, grease and dirt. Terrazzo and ceramic

tile must be abraded to assure adhesion.

WARNING! Do not sand existing resilient tile, sheet flooring, backing or felt linings. These

products may contain asbestos fibers that are not readily identifiable. Inhalation of asbestos

dust can cause asbestosis or other serious bodily harm. Check with local, state and federal laws

for handling hazardous material before attempting the removal of these floors.

Radiant Heated Sub-floors

Before installing over a radiant heated floor, turn off heat and wait until the floor has reached room

temperature. After installing the floor return the heat to the previous setting.

➡ Caution: The slab surface must never exceed 85° F in temperature.

Preparation

Remove all moldings and wall base and undercut all door casings with a hand or power jamb saw using a

scrap piece of flooring as a guide.

“Racking the Floor”

Whether you choose to install the floor with glue, nails, or staples start by using random length planks from

the carton or by cutting four to five planks in random lengths, differing by at least 6”. As you continue

working across the floor be sure to maintain the 6” minimum between end joints on all adjacent rows.

Never waste material, use the left-over pieces from the fill cuts to start the next row or to complete a row.

➡ Note: When installing a pre-finished wood floor be sure to blend the wood from several cartons to

ensure a good grain and shading mixture throughout the installation.

GLUE DOWN INSTALLATION GUIDELINES

There are two ways to install when using Mohawk Hardwood Floorings’ adhesive (wet lay - meaning to

lay directly into wet adhesive and dry lay method - meaning to allow the adhesive to flash or tack up).

Caution: Whether you choose to install using the dry or wet method follow all guidelines set by

the adhesive manufacturer as well as Mohawk Hardwood Flooring. By not adhering to the

guidelines you can void your flooring warranties.

Step 1 – (Wet Lay Method)

Select a starter wall. It is recommended to start the installation along

an exterior wall, it’s more likely to be straight and square with the

room. Measure out from the wall the width of two planks plus 1/4”

and mark eachend of the room and snap your chalk line.

1.7.4 Mohawk Hardwood Installation Guide

Step 2

Spread Mohawk Hardwood

Flooring Adhesive from the chalk

line to the starter wall using the

recommended trowel (3/16” X 1/4”

X 1/2” v notch). It is important to

use the correct trowel at a 45° angle

to get proper spread of adhesive

applied to the sub-floor, which will

produce a proper and permanent

bond. Improper bonding can cause

loose or hollow spots.

➡ Note: Change the trowel every 2000 to 3000 square feet due to wear down of the notches. This

assures you always get the proper spread of adhesive.

Flash and Open Time for Adhesive

Figures shown below are for trowel sizes indicated on container directions.

Substrate Conditions

Hot & Ambient & Cold & Hot & Ambient & Cold &

Dry Dry Dry Humid Humid Humid

Plywood/OSB

Flash Time 40 min 35 min 35 min 20 min 25 min 25 min

Open Time 180 min 180 min 180 min 85 min 100 min 100 min

Vinyl/Non-Porous

Flash Time 45 min 45 min 40 min 30 min 30 min 30 min

Open Time 200 min 210 min 210 min 110 min 120 min 130 min

Concrete

Flash time 30 min 30 min 30 min 20 min 20 min 20 min

Open Time 160 min 160 min 165 min 75 min 80 min 95 min

Flash Time The necessary waiting period between the application of the adhesive and the installation

of the wood floor.

Open Time The maximum amount of time recommended for the adhesive to be exposed to air before

the installation of the wood floor.

1.7.5

Engineered Plank & Strip Glued, Staple/Nail Down or Floating Installation

Step 3

Install the first row of starter planks with the tongue facing the starter wall and secure into position. Alignment

is critical and can be achieved by top nailing the first row with finishing nails (wood sub-floor). This

prevents slippage of the planks that can cause misalignment.

➡ Note: The planks along the wall may have to be cut to fit since most walls are not straight, and

leaving an expansion space is not necessary with Mohawk Flooring’s engineered planks and strips.

Step 4

Once the starter rows are secure, spread 2 1/2 to 3 feet of adhesive the

length of the room. (Never lay more adhesive than can be covered in

approximately 2 hrs.)

Place tongue into groove of plank or strips and press firmly into

adhesive. Never slide planks or strips through adhesive. Use a tapping

block to fit planks snug together at side and butt ends.

Test for proper bond by occasionally lifting a board and looking for

good coverage (90%), then replace it into the adhesive.

Clean any adhesive off the surface before it cures using Mohawk

Adhesive Towels, using mineral spirits on a clean cloth. BE SURE TO

CLEAN OFF ALL EXCESS ADHESIVE AT THE TIME OF

INSTALLATION, OTHERWISE IT MAY NOT COME OFF ONCE

CURED ONTO THE PRODUCT..

Use 3M Blue Mask Tape to hold planks securely in place as you are

installing and continue the process throughout the installation. Use

caution when using a rubber mallet to butt material together, it can

burnish the finish and cause marring.

➡ Note: Never work on top of the flooring when installing with the

wet lay method.

DRY LAY INSTALLATION GUIDELINES

Step 1

Start by selecting your starter wall and measure out

from the wall 27” when installing 2 1/4” strip

flooring and 30” when installing 3” planks. This

will allow adequate working space. Snap chalk line.

Step 2

Apply adhesive from the chalk line out 2 1/2’ – 3’.

Allow adhesive to flash as per the instructions

affixed to the top of the adhesive container (see

chart on the previous page). The humidity chart

will aid in allowing the appropriate flash time based

Spread this area last

snap a chalk line

27” for 2 1/4

strip

30” for 3” planks

1.7.6 Mohawk Hardwood Installation Guide

on the temperature and humidity.

Secure your starter rows with a straight edge (2’ X 4’s). Install planks and secure with 3M Blue Mask Tape

as you continue throughout your installation. If you must work on top of the newly laid flooring, use a

kneeling board.

Once the remainder of the floor has been installed, go back to the beginning and remove straight edges and

spread adhesive on the remainder of the open sub-floor, allow to flash for the appropriate time and lay

flooring as instructed. Remember that the planks closest to the wall may need cutting to fit due to irregularities

along the wall. When using Mohawk Hardwood Flooring Adhesive it is not necessary to roll the floor.

Clean-Up

Use Mohawk Hardwood Flooring Adhesive Towels to clean as you go, along with Columbia Flooring

Cleaner. Both are easy and convenient to use. Adhesive that has cured on the surface of the flooring can be

difficult to remove and will require the use of Mohawk Urethane Remover. This product has been

recommended by the adhesive manufacturer and is safe for the finish of your pre-finished Mohawk floor.

Once the floor is completed, clean the flooring with Mohawk Flooring Cleaner.

Light foot traffic is allowed after 12 hours but wait 24 hours after installation to remove the 3M Blue Mask

Tape. Once the tape is removed, clean any adhesive residue left from the tape with Mohawk Adhesive

Towels.

STAPLE OR NAIL DOWN INSTALLATIONS

Mohawk Engineered hardwood floors may be installed over wood subfloors using staples or nailing cleats.

When installing Mohawk engineered wood planks or strips by nailing or stapling, it is necessary to use the

proper type of flooring stapler or nailer made for Mohawk Engineered Wood Floors.

Recommended Staplers and Nailers

We have tested and recommend the Bostitch Floor Runner (S3297-LHFZ). The recommended staple for

the Bostitch Floor Runner is their 1” staple (S1397). We have tested and recommend the Power Nailer 50C

nailer using a 11/2” power cleat. You must use the 3/8” or 1/2” adapter as appropriate.

Caution: Mohawk has tested the above recommended tools. Other staplers, staples, nailers and

cleats may work as well; however, since they are not currently recommended, if their use

damages or fails to properly secure the flooring the responsibility is the installers and not

Mohawk.

Step 1

You must staple or nail 1” – 2” from the ends and every 4” – 6” along the edges. This will help insure a

satisfactory installation. It is best to set the compressor PSI at 80 – 85 lbs. to keep the staples from going

through or breaking the tongues. Improper stapling techniques can cause squeaks in the floor.

Adjustments may be necessary to provide adequate penetration of the nail or staple into the nail pocket.

You want to flush in the nail pocket. Use a scrap piece of flooring material to set tools properly before

installation.

Before installation of the engineered flooring begins, install a 6 mil polyethylene layer over the subfloor.

This will retard moisture from below and may help prevent squeaks. Keep in mind there is no complete

moisture barrier system for staple or nail down installations.

1.7.7

Engineered Plank & Strip Glued, Staple/Nail Down or Floating Installation

➡ Note: 15 lb. Roofing felt or resin paper may be substituted for the polyethylene and installed as

below.

Installing 6 mil Polyethylene

Install the polyethylene parallel to the direction of the flooring and allow a 3” overhang at the perimeter.

Make sure each run of polyethylene overlaps the previous run by 6” or more.

Layout the job

Measure out from the ends of your starting wall 2 3/4” when installing 2 1/4” strip flooring or 3 1/2” when

installing 3” planks and mark both ends. Where possible lay the flooring at 90° angles to the floor joists.

Make a chalk line along the starting wall using the marks you made.

Beginning installation

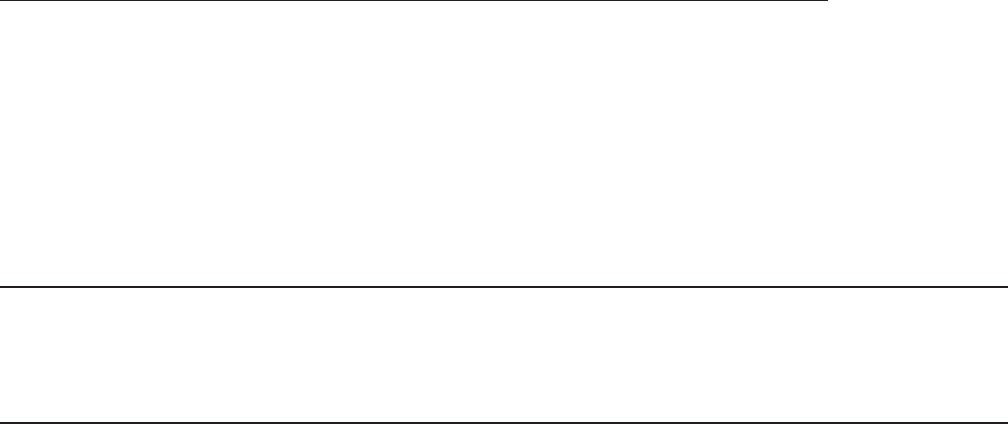

Place the planks with the tongue facing

away from the wall and along your

chalk line. Use brads or small finishing

nails to secure the first starter row along

the wall edge 1” - 2” from the ends and

4” – 6” along the side. Counter sink

the nails and fill with the Mohawk

Filler that blends with the flooring installed. Place nails in a dark grain spot in the board. The base or shoe

molding will cover the nails when installed after completion of the installation.

Blind nail at a 45° angle through the tongues. It will be easier IF YOU PRE-DRILL THE HOLES IN THE

TONGUES. Nail 1” – 2” from the ends and every 4” – 6” along the sides. It will be necessary to blind nail

the next 2 rows. A Stanley BT35 brad nailer with 1” – 1 3/8” brads can also be used to blind nail and no

pre-drilling is needed.

Continue the installation using an engineered wood flooring stapler, using staples or nails recommended

by Mohawk. Nail or staple the flooring 1” – 2” from the ends and every 4” – 6” along the edge tongues.

Final Touches

Install the proper trim molding at the doorways to achieve the transition and along the walls to cover the

edges of any gaps along the wall due to irregularity.

MAINTENANCE

Mohawk Engineered Hardwood Floors are very easily maintained. No wax, no mess. Simply use Mohawk

Floor Cleaner and a specialty terry cloth flooring mop available from flooring retailers.

Step One

Vacuum or sweep your floor to remove any particles that could scratch your floor.

Warning: Vacuums with a beater bar or power rotary brush head can damage a wood floor and should

never be used.

1.7.8 Mohawk Hardwood Installation Guide

Step Two

Apply the Mohawk Cleaner directly to the terry cloth flooring mop, not the floor.

Step Three

Use a back and forth motion with the mop. When the terry cloth cover becomes soiled, simply replace it

with a clean one. Cleaning the floor with a soiled cover could cause streaking. The covers are re-usable so

simply throw the cover in the wash and dry it as you would any towel.

TIPS AND WARNINGS

✔ Vacuum or sweep regularly.

✔ Remove spills promptly using Mohawk Floor Cleaner and a clean white cloth.

✔ Use felt protectors under heavy pieces of furniture and chairs.

✔ Use protective mats at all exterior entrances.

✔ Spiked heels or shoes in need of repair can severely damage your floor.

✔ Never wet or damp mop your wood floors. Water can cause damage to wood flooring.

✔ Never use oil soaps, wax, liquid or other household products to clean your floor.

✔ The sun’s UV rays can change the color of your floor.

✔ Keep animal nails trimmed.

✔ Protect your floor when using a dolly for moving furniture or appliances. Never slide or roll heavy

furniture or appliances across the floor.

✔ If your floor becomes scratched or dull, repairs can often be made using repair accessories.