Bridge Safety Standards

Compliance Manual

October 2018

Office of Railroad Safety

Bridge Safety Standards Compliance Manual

i

Table of Contents

CHAPTER 1 – INTRODUCTION AND GENERAL GUIDANCE.......................................................... 1

I

NTRODUCTION TO THIS MANUAL ............................................................................................... 1

S

AFETY .................................................................................................................................... 1

B

RIDGE SAFETY OVERSIGHT ..................................................................................................... 1

A

CTIVITY-CODE SPECIFIC GUIDANCE ......................................................................................... 2

P

RIORITIZING OVERSIGHT ACTIVITIES ........................................................................................ 4

O

PENING CONFERENCE ............................................................................................................ 6

C

LOSING CONFERENCE ............................................................................................................ 6

D

EFECT TRACKING ................................................................................................................... 6

CHAPTER 2 – FIELD REPORTING PROCEDURES AND FORMS .................................................... 8

I

NTRODUCTION ......................................................................................................................... 8

I

NSPECTION REPORT, FORM FRA F6180.96 .............................................................................. 8

General Instructions ............................................................................................................ 8

Special Instructions–Inspections from/to State Lines ........................................................... 9

Defect Line Item Form FRA F6180.96 ................................................................................10

Violation Recommended Line Item Form FRA F6180.96 ....................................................10

V

IOLATION REPORT NARRATIVE – FORM FRA F6180.111 .........................................................11

General Instructions ...........................................................................................................11

Submission of Photographs as Evidence ............................................................................12

Statements of Witness ........................................................................................................13

S

OURCE CODES ......................................................................................................................17

M

ULTIDISCIPLINE ACTIVITY CODE TABLE OF DEFINITIONS ...........................................................19

B

RIDGE AND TRACK ACTIVITY CODE TABLE OF DEFINITIONS.......................................................29

D

EFECT CODES .......................................................................................................................39

I

NSTRUCTIONS, FORM FRA F6180.96, INSPECTION REPORT .....................................................45

I

NSTRUCTIONS, FORM FRA F6180.111, TRACK VIOLATION REPORT FORM .................................54

CHAPTER 3 – BRIDGE SAFETY STANDARDS ............................................................................. 58

I

NTRODUCTION ........................................................................................................................58

S

UBPART A – GENERAL ...........................................................................................................59

§ 237.1 Application .............................................................................................................59

§ 237.3 Responsibility for compliance .................................................................................60

§ 237.5 Definitions ..............................................................................................................63

§ 237.7 Penalties ................................................................................................................64

§ 237.9 Waivers ..................................................................................................................65

S

UBPART B – RAILROAD BRIDGE SAFETY ASSURANCE ..............................................................65

§ 237.31 Adoption of bridge management programs ..........................................................65

§ 237.33 Content of bridge management programs ............................................................66

S

UBPART C – QUALIFICATIONS AND DESIGNATIONS OF RESPONSIBLE PERSONS .........................70

§ 237.51 Railroad bridge engineers ....................................................................................70

§ 237.53 Railroad bridge inspectors ...................................................................................71

§ 237.55 Railroad bridge supervisors .................................................................................72

§ 237.57 Designation of individuals ....................................................................................72

S

UBPART D – CAPACITY OF BRIDGES .......................................................................................73

§ 237.71 Determination of bridge load capacities ...............................................................74

§ 237.73 Protection of bridges from over-weight and over-dimension loads .......................78

Bridge Safety Standards Compliance Manual

ii

SUBPART E – BRIDGE INSPECTION ...........................................................................................79

§ 237.101 Scheduling of bridge inspections ........................................................................79

§ 237.103 Bridge inspection procedures .............................................................................81

§ 237.105 Special Inspections ............................................................................................82

§ 237.107 Conduct of bridge inspections ............................................................................84

§ 237.109 Bridge inspection records ...................................................................................84

§ 237.111 Review of bridge inspection reports ...................................................................90

S

UBPART F – REPAIR AND MODIFICATION OF BRIDGES ..............................................................91

§ 237.131 Design ...............................................................................................................91

§ 237.133 Supervision of repairs and modifications ............................................................92

S

UBPART G – DOCUMENTATION, RECORDS, AND AUDITS OF BRIDGE MANAGEMENT PROGRAMS ..93

§ 237.151 Audits; general ...................................................................................................93

§ 237.153 Audits of inspections ..........................................................................................93

§ 237.155 Documents and records .....................................................................................94

A

PPENDIX A – SUPPLEMENTAL STATEMENT OF AGENCY POLICY ON THE SAFETY OF RAILROAD

BRIDGES .................................................................................................................................95

A

PPENDIX B – SCHEDULE OF CIVIL PENALTIES ........................................................................ 102

CHAPTER 4 – EXCEPTIONS TO THE STANDARDS .................................................................... 106

I

NTRODUCTION ...................................................................................................................... 106

D

EFECT REPORTS ................................................................................................................. 107

V

IOLATION REPORTS ............................................................................................................. 107

Knowledge Standard ........................................................................................................ 108

Criteria Affecting the Seriousness of a Noncomplying Condition ....................................... 108

Complaint and Accident Investigations ............................................................................. 111

C

OMPLIANCE ORDERS AND COMPLIANCE AGREEMENTS .......................................................... 111

General Instructions ......................................................................................................... 111

Procedures ....................................................................................................................... 111

Docum

entation ................................................................................................................. 112

E

MERGENCY ORDERS ............................................................................................................ 113

General Procedures ......................................................................................................... 113

Technical Considerations ................................................................................................. 114

Scheduling ........................................................................................................................ 114

Inspection ......................................................................................................................... 114

Voluntary Corrective Action .............................................................................................. 115

Refusal to Correct ............................................................................................................. 115

Information Needed to Support Issuance of an Emergency Order .................................... 115

Violation of FRA Emergency Order ................................................................................... 118

E

NFORCEMENT OF THE SAFETY LAWS AND REGULATIONS AGAINST INDIVIDUALS ....................... 118

Bridge Safety Standards Compliance Manual

1

CHAPTER 1 – Introduction and General Guidance

Introduction to This Manual

The Bridge Safety Standards Compliance Manual provides technical guidance to Federal bridge

specialists. This manual provides guidance for enforcement of Title 49 Code of Federal

Regulations (CFR) Part 237, Bridge Safety Standards (BSS). The guidance provided in this

manual may be revoked or modified without notice by a memorandum from the Associate

Administrator for Railroad Safety and Chief Safety Officer. This manual does not modify, alter,

or revise the regulatory provisions in the Bridge Safety Standards (BSS) in any way.

Comments, additions, and suggestions for future changes should be directed to the Chief

Engineer–Structures for consideration.

Bridge specialists should refer to this manual as often as necessary for clarification of Federal

Railroad Administration (FRA) regulation interpretation and policy. When a bridge specialist is

unsure of meaning or intent in this manual, the bridge specialist should promptly contact the

Chief Engineer–Structures for guidance. This manual can be viewed at

http://www.fra.dot.gov/eLib/Find#p1_z50_lCM_s66_s43_s67_kcompliance%20manual.

Safety

FRA’s first priority is safety. Therefore, all activities are to be conducted with personal safety

and the safety of accompanying personnel in mind. Bridge specialists must conduct activities in

accordance with the safety instructions contained in the General Manual. Guidance for Roadway

Worker Protection (RWP), bridge worker safety, and on-track roadway maintenance machine

safety is contained in the Track and Rail and Infrastructure Integrity Compliance Manual,

Volume III.

Bridge Safety Oversight

A bridge specialist’s primary duty is to conduct inspections to determine whether the railroads

are complying with the BSS as well as railroad workplace safety regulations (bridge worker

safety, roadway worker protection, and roadway maintenance machine safety). Effective

inspection requires identification, evaluation, and reporting of conditions and practices that fail

to meet minimum Federal compliance requirements.

All instances of noncompliance with the BSS are to be documented as defects on the Form FRA

F6180.96, Inspection Report (Form FRA F6180.96 or F6180.96). Refer to Chapter 2, Field

Reporting Procedures and Forms, for more information.

Because the purpose of regular inspection activity is to evaluate the performance of the carrier

and the carrier’s representatives in conducting thorough inspections and complying with the

BSS, an evaluation of bridge inspection records maintained by the carrier, as required by 49 CFR

§ 237.109, is also necessary.

Bridge Safety Standards Compliance Manual

2

The adequacy of the carrier’s bridge inspections is determined by evaluating what is recorded on

the carrier’s inspection reports and whether these reports reflect the actual conditions of the

bridge structure.

Prior to inspection, the following preparations should be made:

• Obtain the names and locations of the supervisor’s territory to be inspected.

• Advise the supervisor of the territory to be inspected and invite them to have a railroad

representative accompany you.

• Set a date, time, and location for the inspection.

• Make appropriate transportation arrangements necessary to execute the inspection.

• If you must change the date, time, or location, make every effort to contact the railroad as

soon as possible to advise it.

• Always have a copy of the BSS and this manual as references.

• Carry measuring and inspection equipment (tape measure, level, string line, plumb bob,

hammer, binoculars, etc.).

Bridge specialists should review the following information before the inspection:

• Current carrier bridge management program (BMP)

• Recent carrier bridge inspection reports

• Timetables and special instruction for speeds, restrictions, and load capacities

• Current slow orders

• Train, tonnage, and hazardous material information

• Current and recent program work

For information on general FRA inspection policies, bridge specialists should review the General

Manual, Chapter 2, for guidance about issues such as property entry, refusal to permit

inspections, forcible interference with official duties, and release for entry, as well as strike or

labor disputes.

Activity-Code Specific Guidance

Ideally, the first bridge safety oversight activity to be performed would be a BMP review.

However, any of the following activities can be conducted independently of one another and at

any time, or as a result of an inquiry, complaint, accident, or natural event.

BIR – Bridge Inspection Record Field Audit – A Bridge Inspection Record Field Audit is used

to evaluate whether a bridge inspection record accurately documents the condition of the subject

bridge. The bridge specialist should exercise care when picking bridge inspection reports to

audit to ensure that a representative sample is selected. In addition to selecting bridges that

appear to have deterioration, reports for bridges that appear to be in good condition should be

Bridge Safety Standards Compliance Manual

3

sampled to ensure that inspection reports accurately document field conditions. Further, the

audit must be performed in two directions: first, evaluate whether conditions shown on the

report actually exist on the bridge; and second, evaluate whether all deficient bridge conditions

observed are documented on the report.

BMP – Bridge Management Program Review – (Note: The acronym BMP has two uses. In

the title of this paragraph and in one reference in the Bridge and Track Activity Code Table of

Definitions, it is the activity code used in the Railroad Inspection System for Personal Computers

(RISPC). In the body of this paragraph and elsewhere in this manual, BMP is the abbreviation

for Bridge Management Program.) A BMP review is a method used to determine whether a

track owner has adopted a bridge management program, and whether it complies with the

requirements stipulated in 49 CFR Part 237, Bridge Safety Standards. It is important that the

bridge specialist perform a thorough BMP review to ensure that all occurrences of

noncompliance with the BSS are documented on Form FRA F6180.96. Use the BMP checklist

to ensure that all required items are covered in the review and included on Form FRA F6180.96.

Follow-up reviews need to be equally as thorough as initial reviews since additional

noncompliant conditions may have been introduced during revision of the earlier BMP.

BREC – Bridge Inspection Record Review – A Bridge Inspection Record review is an

opportunity to verify that bridge inspection records adhere to the requirements of the track

owner’s BMP and the BSS. This activity code is used for the office audit of bridge inspection

records/reports. Unless all of a track owner’s inspection reports for a given territory and year are

being reviewed, care must be taken to select a random sample. Records selected must be

evaluated to determine whether they conform to the requirements of the track owner’s BMP and

include all information required by 49 CFR §§ 237.109(b) and 237.109(c) of the BSS.

Timeliness of inspections and submission of completed inspection records should also be

evaluated.

BSSE – Bridge Safety Standards Compliance Evaluation – This code encompasses multiple

activities involved in determining whether a track owner is following the policies and procedures

outlined in their BMP. These activities include, but are not limited to:

• Evaluating the accuracy of the track owner’s railroad bridge inventory.

• Verifying that bridge inspections are being conducted in conformance with the track

owner’s bridge inspection procedures.

• Determining if inspections are being documented on the specified form, using the correct

nomenclature, and following the BMP-specified numbering/identification protocol.

• Determining if weight and dimension restrictions are being followed.

• Determining whether inspection reports are being adequately reviewed.

• Verifying that instructions for the protection of train operations following natural or man-

made accidents are being followed.

• Determining whether internal audits are being performed as specified in their BMP.

• Determining whether repairs/modifications that affect bridge load capacity are being

Bridge Safety Standards Compliance Manual

4

supervised by a designated Railroad Bridge Supervisor, following plans, specifications,

and/or procedures developed by a qualified, designated Railroad Bridge Engineer.

Use of other bridge-related activity codes such as BREC and BIR, in conjunction with BSSE, is

permitted and expected. All activities performed under activity code BSSE are to be identified

on Form FRA F6180.96 to document the extent of the evaluation. Use the BSSE checklist to

organize your notes and ensure a complete inspection report.

BWI – Bridge Waiver Investigation – Evaluating a petition for a waiver of compliance with

the requirements of the BSS requires determining whether the track owner’s petition proposes

alternative methods of providing for railroad bridge safety at least equal to the level that would

be provided were the regulations followed. The bridge specialist should conduct such an

investigation in a manner similar to performing a BMP review to ensure a complete and

thorough evaluation.

Prioritizing Oversight Activities

To efficiently allocate FRA’s resources throughout the Nation and ensure the safety and viability

of the railroad system, bridge specialists should prioritize their inspection activities by

considering the following characteristics:

• Operational size of a railroad

• Tonnage – annual tonnage traveling over a railroad’s tracks

• Passenger trains operating on a railroad’s tracks

• Critical energy routes

• Hazardous materials (toxic inhalation hazard (TIH)/poison by inhalation hazard (PIH))

transported on a railroad’s system

• Speed authorized for trains on tracks

• Compliance history of a railroad

• Accident history of a railroad

• Strategic Rail Corridor Network (STRACNET) Route within a railroad’s track system.

In addition to the above, previous safety reviews, audits, and travel efficiency should be

considered. Prioritize Class III and other small railroads that do not handle passengers,

hazardous materials, or energy products by their operational size and compliance history.

To effectively analyze and manage risk related to the bridge safety program, FRA established a

systematic, data-driven, risk-based methodology for prioritizing BMP reviews. The output of

this model is a list of track owners ranked according to the potential for a bridge failure and the

impact on operations and safety should a failure occur. The prioritized list of track owners

enables FRA to efficiently plan and allocate resources for BMP reviews, and establishes a

framework for other bridge safety activities.

Bridge Safety Standards Compliance Manual

5

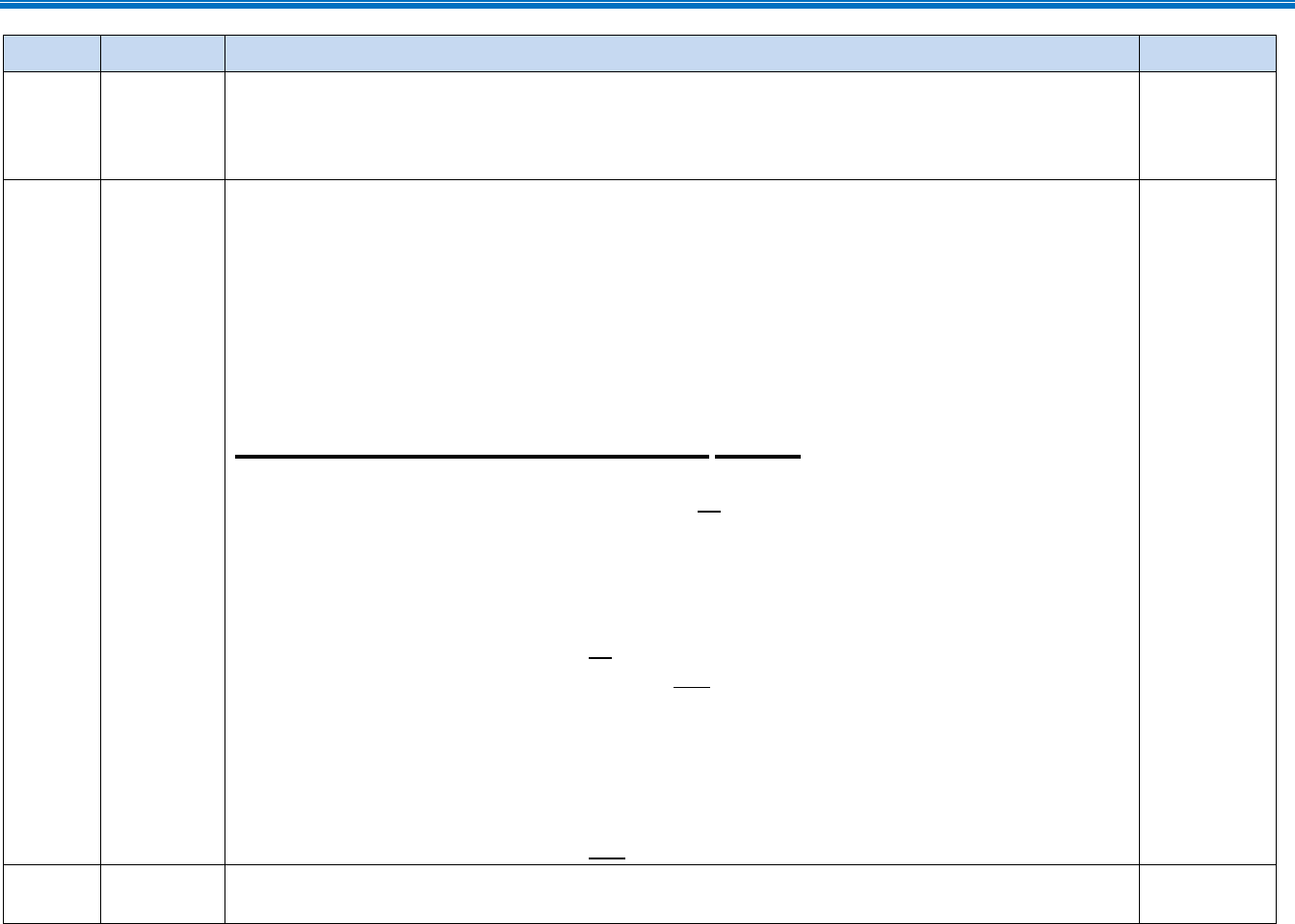

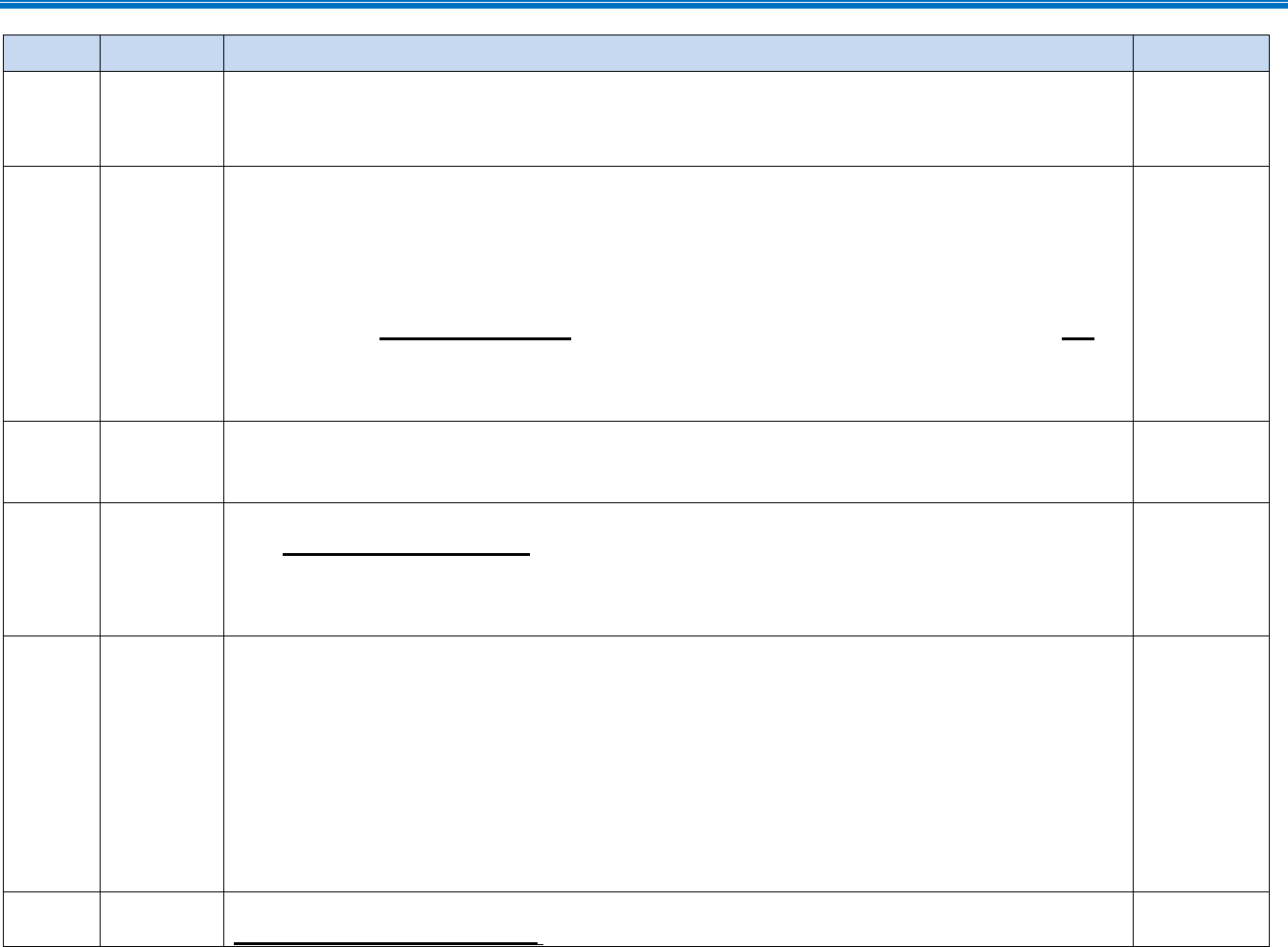

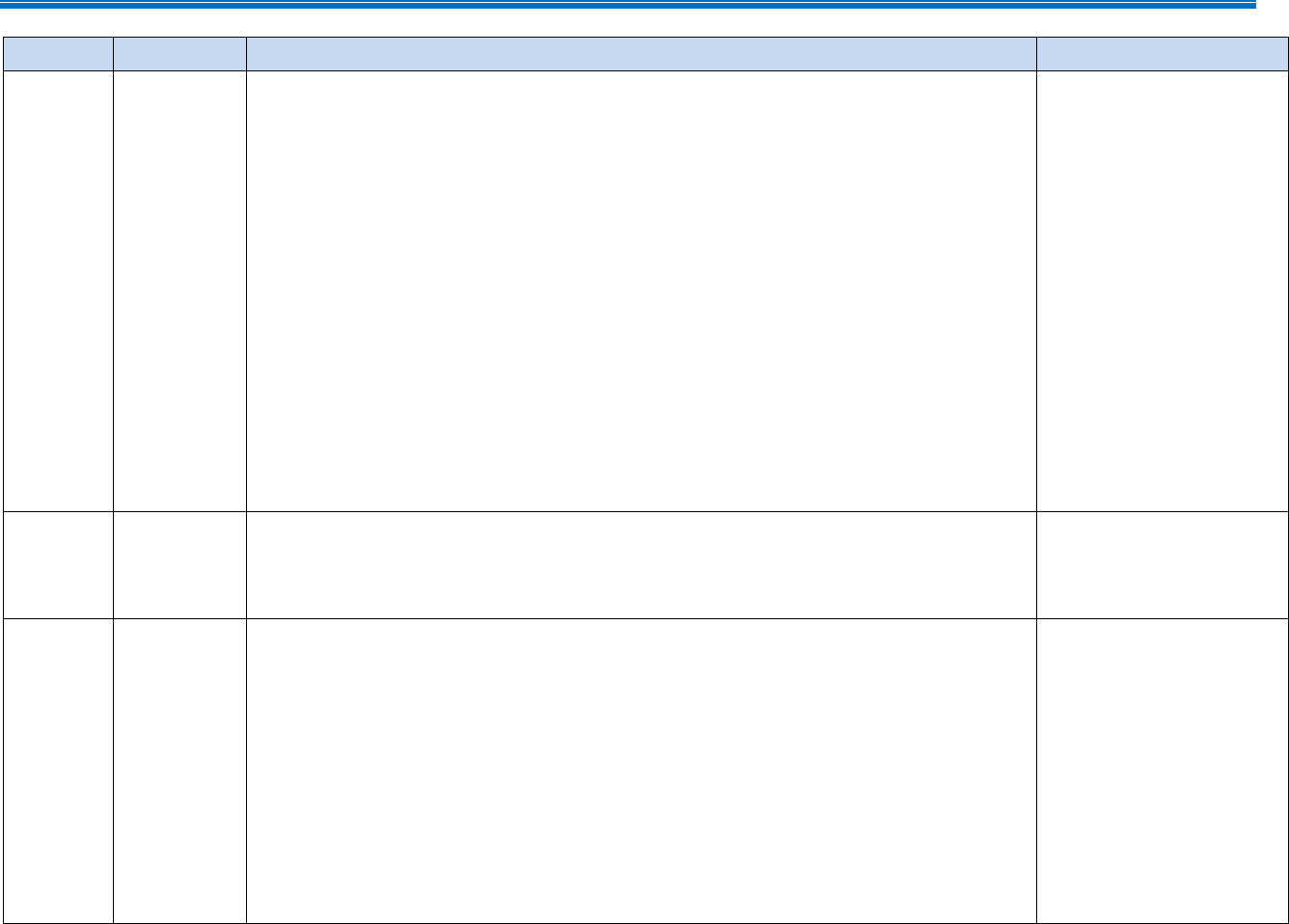

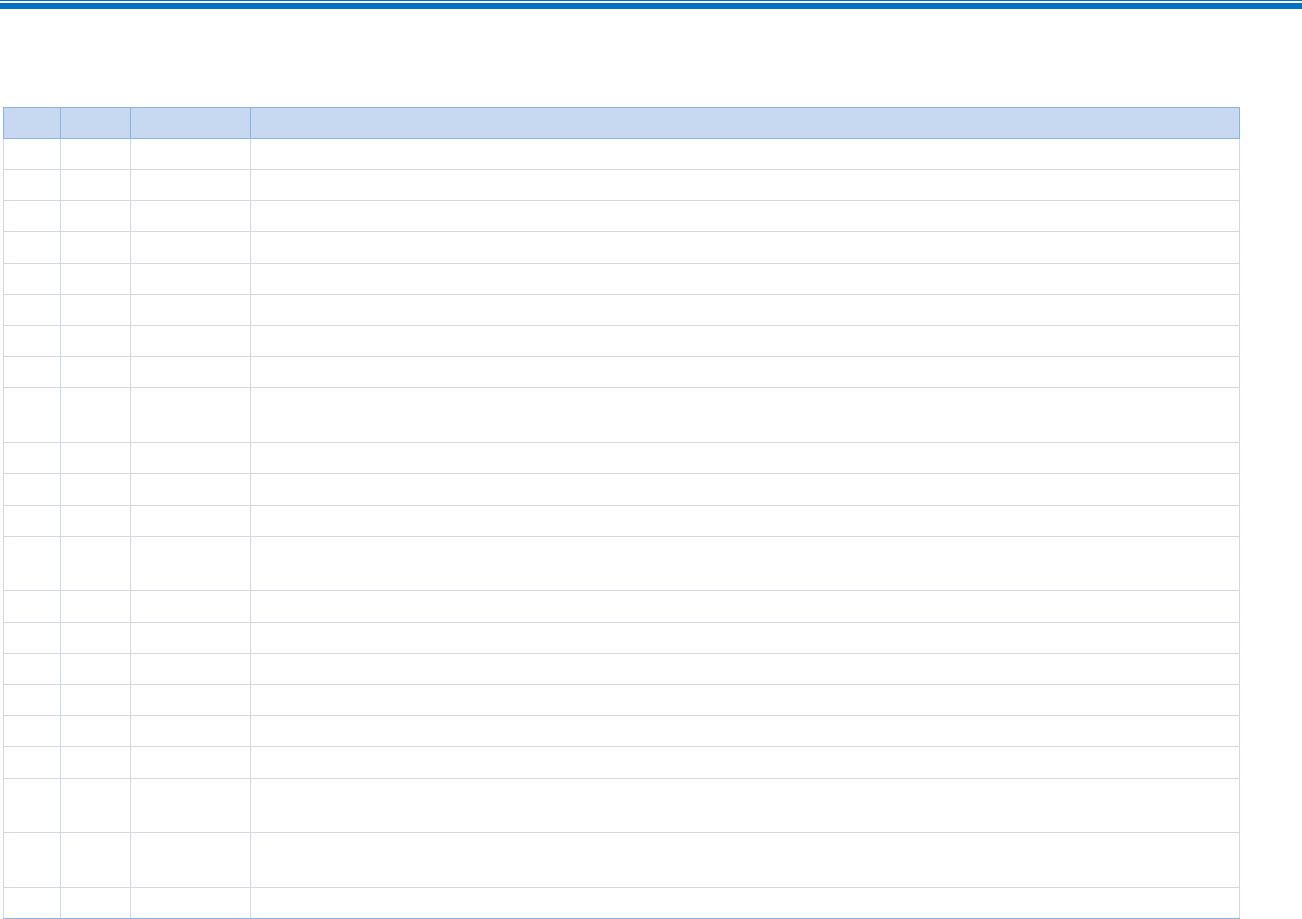

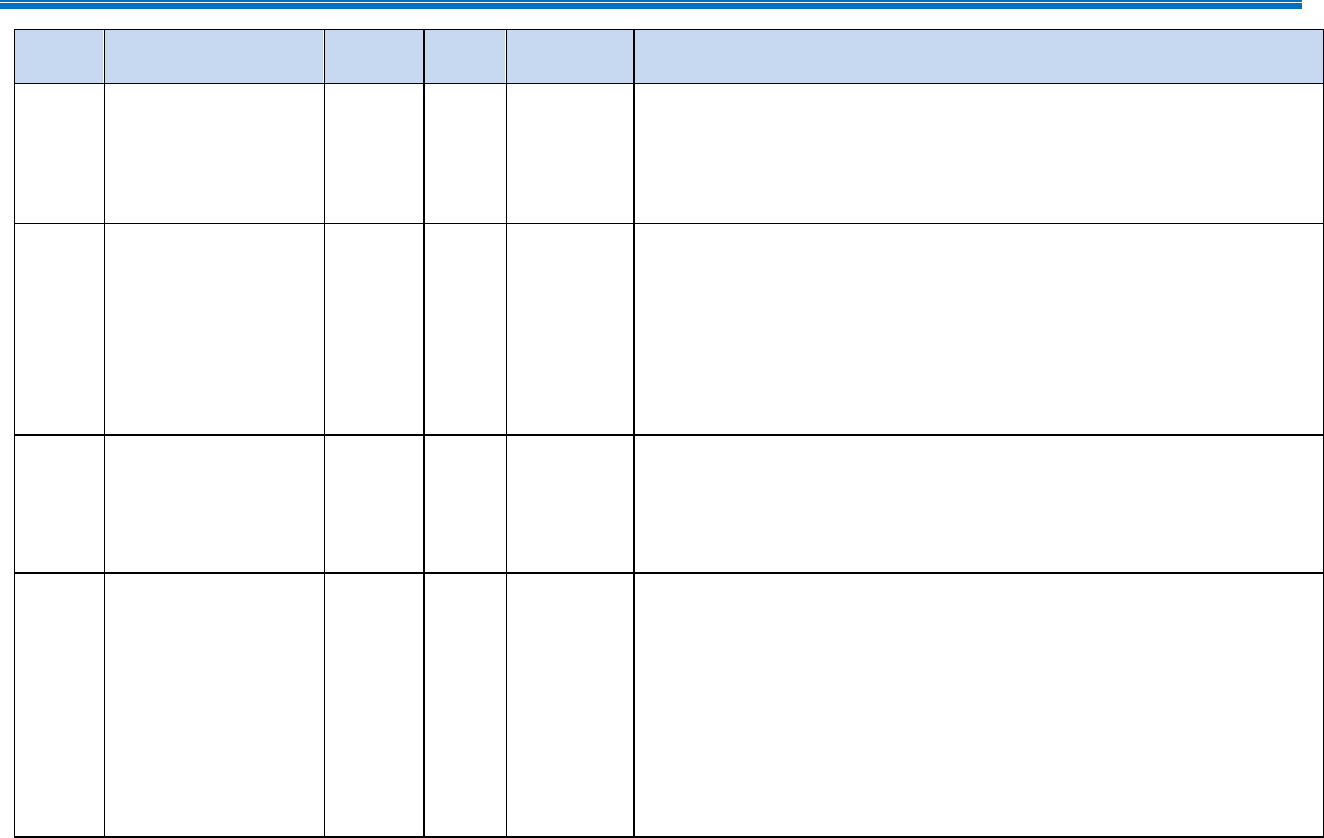

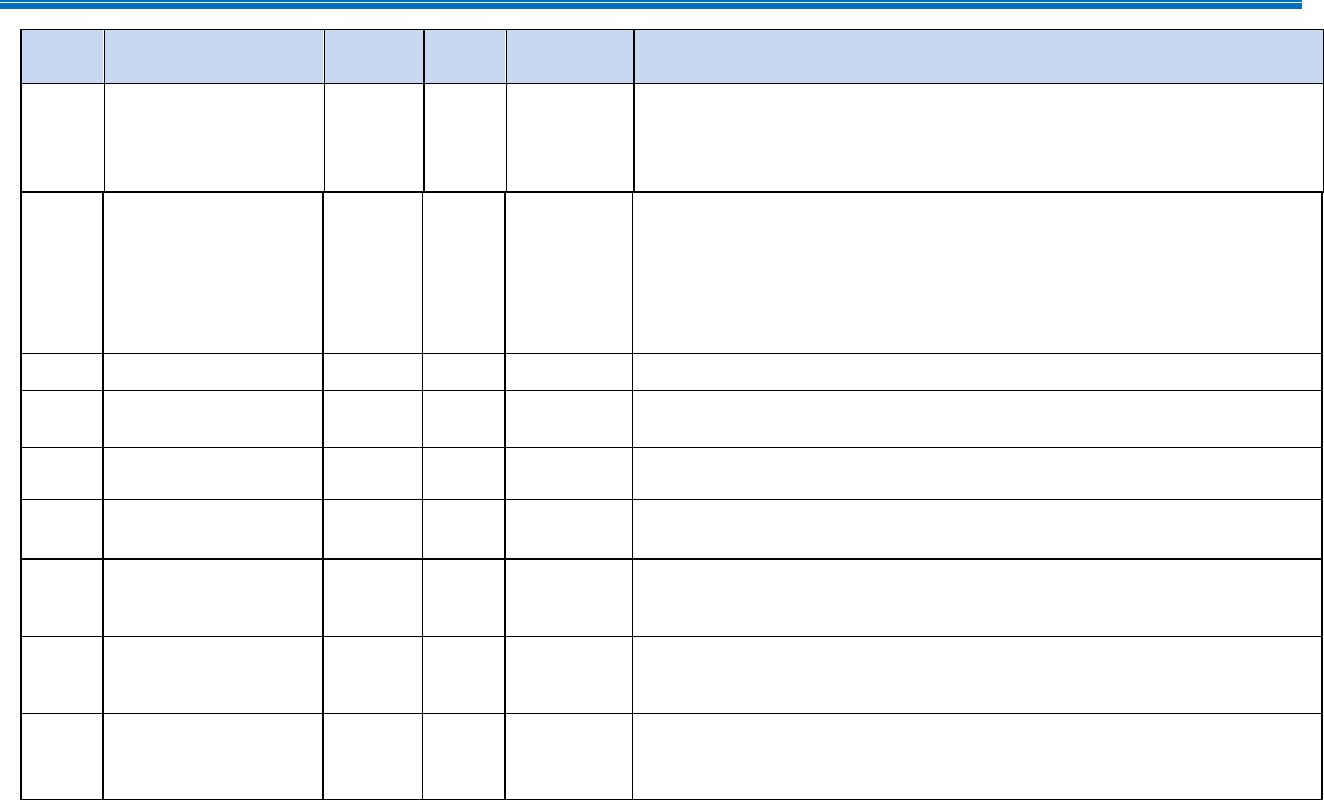

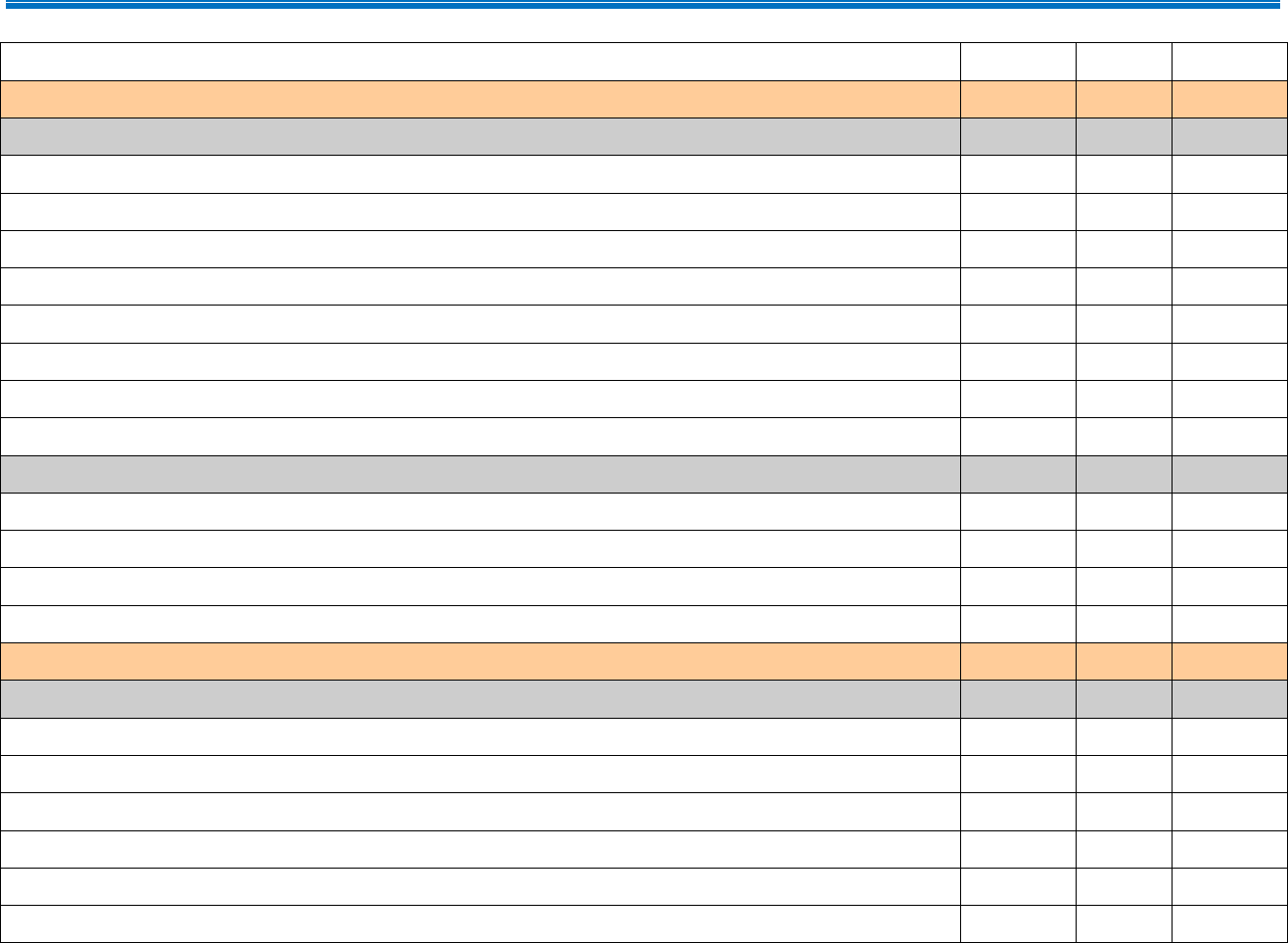

BMP reviews will be prioritized using a model that evaluates the following criteria:

Criteria Criteria Description Priority Levels

1

Operational

Size

(miles)

Total length of railway routes open for

public passenger and freight services.

Due to maintenance requirements, a larger

size indicates a higher potential for safety

issues.

< 20 1

20 - 40 2

40 - 200 3

200 - 1000 4

> 1000 5

2

Total Train

Miles

(per year)

Total mileage operated by trains in a

calendar year.

Due to maintenance requirements, a larger

size indicates a higher potential for safety

issues.

< 10k 1

10k - 20k 2

20k - 200k 3

200k - 2M 4

> 2M 5

3

Passengers

Carried

(per year)

Railroads carrying passenger trains are

evaluated due to the potential loss of life if

bridge failure occurs.

Impact of an incident would be high.

Priority level is based on number of

passengers carried in a calendar year.

< 10k 1

10k - 100k 2

100k - 1M 3

1M - 10M 4

> 10M 5

4

Energy

Products

(tank

cars/year)

Railroads carrying energy products are

evaluated due to the potential loss of life

and environmental damage if bridge failure

occurs.

Impact of an incident would be high.

Priority level is based on the number of

tank cars per year where energy products

are carried by railroad.

< 1k 1

1k - 5k 2

5k - 10k 3

10k – 220k 4

> 220k 5

5

Hazardous

Materials

(tank

cars/year)

Railroads carrying hazardous materials are

evaluated due to the potential loss of life

and environmental damage if bridge failure

occurs.

Impact of an incident would be high.

Priority level is based on the number of

tank cars per year where hazardous

materials (TIH/PIH) are carried by railroad.

< 100 1

100 - 500 2

500 - 1k 3

1k – 15k 4

> 15k 5

6

Strategic

Rail

Corridor

Network

Does railroad operate over a portion of the

STRACNET?

No 0

Yes 5

Bridge Safety Standards Compliance Manual

6

Opening Conference

Before starting an inspection, bridge specialists should introduce themselves to all present and

obtain a list of individuals participating in the inspection. A bridge specialist may then explain

the reason for the inspection as:

• Regular – To ensure the carrier’s process is adequate in finding, reporting, and remedying

non-BSS-compliant conditions.

• Follow-up or “Re-inspection” – Regular inspection to ensure proper remedial action.

• Complaint – Inspection of unsafe conditions alleged by an individual, group, or entity.

Caution must be used not to identify the complainant. It is not mandatory to divulge that

you are on a complaint investigation, as it may compromise the investigation. Bridge

specialists should consult, if appropriate, with appropriate regional track or signal

specialists.

• Accident – Investigations of derailments or accidents, etc.

• Waiver – Investigation for relief from BSS.

• Special Inspections – Focused inspections or program enforcement.

During the Workplace Safety Briefing prior to the inspection, all parties involved must

understand that FRA’s goal is to help the railroad improve safety, and that we welcome

suggestions and ideas.

Closing Conference

Upon completion of an inspection, the bridge specialist must provide the railroad representative a

report (F6180.96) with all conditions that do not meet minimum Federal BSS regulations. Field

reporting is discussed in Chapter 2. The reporting of exceptions to the standards is discussed in

Chapter 4.

Defect Tracking

All defects must be tracked on Form FRA F6180.96 and corrective actions noted. Corrective

actions include remediation, procedural changes, training, and follow-up. Defects that cannot be

remediated or do not warrant follow-up must be recorded on F6180.96, but considered closed

once noted.

If a defect is identified, but a civil penalty is not recommended, the bridge specialist must use the

following process to track corrective action. Since 49 CFR Part 209 Subpart E only requires the

regulated entity to complete and return the remedial action report (back page of the F6180.96)

when a civil penalty is being recommended, the track owner’s response is voluntary and not

required.

1. Create a F6180.96 with a line item that includes a comment indicating the bridge

specialist is requesting remedial action reports be completed for whatever line items of

F6180.96 the bridge specialist deems necessary to ensure proper remedial action is

Bridge Safety Standards Compliance Manual

7

applied. (Example comment: “Reporting of your remedial action is requested for Items

#3 and #6. The completion of a remedial action report for these defects is not required by

regulation; completing the report is voluntary and assists FRA in documenting corrective

actions without re-inspection. Within 60 days, please complete the remedial action report

(on the last page of this report) by entering the appropriate remedial action code and

providing a brief description of the corrective action you took in the narrative section,

then return it to me at fi[email protected].”)

2. Enter a remedial action request for each line item that warrants follow-up (Example

comment: “Please complete the remedial action report for this defect indicating your

corrective action.”). In completing the report, verify “O” is selected in the Written

Notifications to FRA of Remedial Action box for each line item requesting a voluntary

response. Place a “W” in the Railroad (Remedial) Action Code box to indicate a

voluntary remedial action report is being requested. Initially, the Railroad Action Code

date is to show the date of the inspection.

3. Provide the track owner with the inspection report.

4. If the track owner opts not to provide the remedial action within the timeframe specified

(typically 60 days), the bridge specialist must contact the track owner to confirm the

remedial action was completed and, if necessary, conduct a re-inspection to ensure the

remedial action was satisfactory.

5. When the remedial action report is returned or when the remedial action follow-up has

been completed, the bridge specialist must enter the updated information into the

remedial action reporting section of RISPC. This will document the follow-up and

remedial action.

6. At least once per month, bridge specialists must run a query on the Safety Data Secure

Site to determine which defects have not been remediated within the specified timeframe

and plan appropriate follow-up.

This process ensures compliance with the BSS, documents remedial actions taken, and aids in

follow-up prioritization planning.

If a bridge specialist notifies a railroad both that (1) assessment of a civil penalty will be

recommended for the railroad’s failure to comply with a provision of the BSS, and (2) that a

remedial actions report must be submitted, the railroad must report actions taken to remedy that

failure to the bridge specialist within 30 days after the end of the calendar month in which such

notification is received. This requirement, found in 49 CFR Part 209, Subpart E, is outlined in

the “Reporting of Remedial Actions” section of Chapter 3 of the General Manual.

Bridge Safety Standards Compliance Manual

8

CHAPTER 2 – Field Reporting Procedures and Forms

Introduction

Bridge specialists must record each field inspection on Form FRA F6180.96 (also called “Form

96” and “F6180.96 report”). Inspection reports must be completed and promptly submitted, even

when an inspection is free of defect observations. The data contained in each Form FRA

F6180.96 (including a railroad’s reply to corrective action items) transfers to FRA’s safety

database for processing to permit the generation of several management reports. This data helps

to determine the effectiveness of the overall inspection program, the degree of compliance, and

the effect of the BSS on reducing bridge-related accidents.

Inspection Report, Form FRA F6180.96

General Instructions

This section describes the methods used to prepare an inspection report. Since January 1995,

inspectors have been recording their inspection activities on a multidiscipline form, Form FRA

F6180.96. The purpose of the form is to record inspections and defects for placement into

FRA’s safety database.

RISPC provides inspectors with the capability to enter inspection data via their laptop computers.

This program allows inspectors to maintain electronic records, which facilitates data analysis.

Throughout RISPC, help instructions are available to assist in the navigation and use of the

software (by using the menu’s “Help” selection or the question mark icon).

Each inspector engaged in field inspection activities must promptly complete one or more

F6180.96 reports as necessary, sign them electronically, and submit the completed F6180.96

reports to the railroad representative. Electronic RISPC-generated inspection report entries are

the preferred method to be used.

Bridge specialists must provide notice of defective conditions found on the day of the inspection

by either: 1) an electronic PDF copy of F6180.96 (email or another electronic medium) or 2)

verbal notification followed up promptly by a PDF copy of the F6180.96. If F6180.96 reports

contain line items recommending a civil penalty, then a copy, electronically signed by the bridge

specialist, must be provided to the railroad representative.

For instructions on the completion of each field in Form FRA F6180.96, refer to Instructions,

Form FRA F6180.96, Inspection Report, later in this chapter.

Bridge Safety Standards Compliance Manual

9

Special Instructions–Inspections from/to State Lines

Complete an inspection report that begins within a State and terminates at the State line as

follows: Enter the name of the community (if not originating in a community, use the county)

nearest the inspection starting point in the “From City” block on the inspection report and the

State line name from the drop-down menu in the “Destination City” block to indicate the State

line. A four-digit artificial identifier code, starting with the digits “99,” to indicate a State line,

followed by the two-digit State code for the adjacent State, is in the drop-down menu. For

example, an inspection conducted from Erie, PA, to Ashtabula, OH, would be reported on two

separate reports as follows:

First Report

From

Destination

City:

Erie

2640

State:

PA

42

City:

PA/OH State line

9939

County:

Erie

C049

County:

Erie

C049

Second Report

From Destination

City: OH/PA State Line 9942

State: OH 39 City: Ashtabula 0330

County: Ashtabula C007 County: Ashtabula C007

Inspection reports should be numbered consecutively. They can then be associated with each

other in a listing of inspection activity, and a clear picture of the location of the entire inspection

will be available.

An inspection crossing an entire State must show State line identifiers at each end, and must be

associated with adjoining inspection reports by use of consecutive report numbers. For example,

report an inspection from Pittsburgh, PA, through WV, to Columbus, OH, as follows:

First Report

From

Destination

City:

Pittsburgh

6600

State:

PA

42

City:

PA/WV State Line

9954

County:

Allegheny

C003

County:

Allegheny

C003

Bridge Safety Standards Compliance Manual

10

Second Report

From

Destination

City:

WV/PA State Line

9942

State:

WV

54

City:

WV/OH State Line

9939

County:

Brooke

C009

County:

Brooke

C009

Third Report

From

Destination

City:

OH/WV State Line

9954

State:

OH

39

City:

Columbus

1800

County:

Jefferson

C081

County:

Franklin

C049

Use a county or nearest city code for inspections beginning or ending at international borders

(e.g., Canada or Mexico).

Note: When an inspection occurs at one point only, for example an inspection within the

confines of a yard in one municipality, it is not necessary to fill in the “destination” fields.

Defect Line Item Form FRA F6180.96

Bridge specialists must upload their RISPC inspection reports on a weekly basis. If an error is

discovered requiring correction of a report, then the corrected report must be issued to the

railroad representative. Furthermore, as soon as possible, the corrected report must be uploaded

to FRA’s data contractor.

When making an unaccompanied inspection, the bridge specialist must deliver a copy of the

report to the railroad personnel having jurisdiction in the area covered by the report. However,

when an inspection such as one from a train occurs and no defects are noted, it is not necessary

to deliver a copy of the report.

In the Bridge and Structures discipline, do not mix defect-only line items and items checked

“yes” in the “Violation Recommended” field on a Form FRA F6180.96. In the case where a

bridge specialist discovers defect items and violation items during an inspection, these will

require at a minimum two separate reports (one with defects only and another with violation

items only). See below for line items with a recommendation for violation.

Violation Recommended Line Item Form FRA F6180.96

Bridge specialists must complete a separate Form FRA F6180.96 for any items identified as

recommended for violation. However, the above instructions pertaining to uploading and

corrections also apply to reports containing items checked “yes” in the “Violation

Recommended” field. In addition, carefully monitor the “Written Notification to FRA of

Remedial Action Required” field to ensure railroads are complying with this requirement.

Bridge Safety Standards Compliance Manual

11

Failure of the railroad to comply with the written notification requirement must be considered for

a violation (Part 209, Section 405(a)).

Multiple violation line items on a F6180.96 must be of the same CFR part, because all items

from such a report will automatically populate into a Form FRA F6180.111 violation narrative

report (see below).

Violation Report Narrative – Form FRA F6180.111

General Instructions

It is always necessary to provide supplemental information to a Form FRA F6180.96 by writing

a narrative report (Form FRA F6180.111) when recommending a violation. These written

narratives will accompany the Form FRA F6180.96.

In RISPC, use F6180.96 forms that contain items recommended for civil penalty to generate a

Form FRA F6180.111. Open the RISPC main menu and perform the following actions:

1. Select “Other Programs”

2. Select “New Violation Report”

3. At the blank violation screen, select “New Report”

4. Highlight the report and line item number you want and click on “Select and Create

Violation Report”

5. Bridge specialists are to enter their sequential violation number and click on “OK”

Note: When recommending a violation for a Roadway Workplace Safety item, select the Track-

214 form. This will open a Part 214 Railroad Workplace Safety Violation Report Form, FRA

F6180.119.

To complete each field in the Form FRA F6180.111, refer to Instructions, Form FRA F6180.111,

Track Violation Report Form, later in this chapter.

A narrative submitted with an inspection report must contain sufficient detail to completely

describe and support the inspection activity. Copies of all pertinent data should also be furnished

to further support the inspection activity; pertinent data includes railroads’ plans, records,

bulletins, or orders; any pertinent photographs; the names and titles of railroad employees who

were witnesses; the time of day when the inspection or investigation was conducted; and the

location of any violation with reference to some fixed object. GPS coordinates, if available, may

also be used.

When filing a violation report, take great care to obtain adequate evidence to support each

element of each violation recommended in the violation report. This should include evidence

obtained through personal observation and/or records indicating noncompliance.

Bridge Safety Standards Compliance Manual

12

If pertinent, include copies of previous FRA reports or the railroad’s own records to document

the railroad’s prior knowledge of the presence of the defect. Establish knowledge of a defect by

constructively showing that the defect is of such a nature that the railroad would have known of

the defect from past inspections. In this regard, it is helpful to note the date of the railroad’s last

inspection (and include the railroad’s last inspection record) and explain why the condition must

have been present at that time by stating that this type of condition takes a longer time to develop

than the time between the railroad’s last inspection and FRA’s inspection. See Chapter 4 of this

manual for additional instructions concerning the knowledge standard.

In the narrative report, bridge specialists must be careful to identify all circumstances or facts

that they did not witness by stating the source of such information. If necessary, attach a report

of an interview to the narrative report. Identify all copies of records by providing the name, title,

and address of the custodian of original records.

If more than one count (or occurrence) is listed in a line item of an inspection report, the

narrative of the violation report must clearly state whether all counts are being recommended as

separate violations or as one violation for the entire line item, as the intent is not always clear. If

separate violations are being requested for each count, the Transmittal of Violation Report cover

sheet must list each violation as a separate line item (the Railroad Enforcement System (RES)

must list each violation as a separate line item as well unless multiple days are being requested).

This will ensure that FRA’s Office of Chief Counsel (RCC) is aware of both the bridge

specialist’s intent and the Chief Engineer–Structures’ approval of the number of counts

requested. Note that entering the violations as multiple occurrences on F6180.96 in RISPC

automatically generates a footnote indicating that penalties have been assessed for 2 or more

days on which the violation continued, which is not correct in many cases.

Submission of Photographs as Evidence

Photographs can be very strong evidence in support of a violation. When using photographs in

the violation narrative package, explain what each photograph shows. Clearly identify what each

photograph illustrates to support the violation. In violations with multiple counts or line items,

caption each photograph to link it to a specific violation item (e.g., CES_001, Line Item 2).

Photographs must be in digital format. It is acceptable to place descriptions or pointers using

software to help the reader understand the nature of the violation. However, photographs must

not be digitally manipulated in any manner to alter the appearance of any item or element in the

photograph. Digital photographs must be annotated to indicate that there are no electronic

alterations.

Bridge Safety Standards Compliance Manual

13

Statements of Witness

Unless a violation is substantiated by a bridge specialist’s personal knowledge, the railroad’s

own records, or admissions of railroad officials contained in reports of interview, the violation

report should be accompanied by one or more witness statements on the appropriate “Statement

of Witness” form. (That form is designed for use when obtaining statements by railroad

employees; if a statement is being obtained from a nonemployee, consult RCC about how to

proceed.) The witness statement must clearly substantiate any elements of the violation not

established by other evidence. As in any case where a violation report is based on information

received from a complainant, neither the report nor any of its attachments should reveal that the

case arose from a complaint or identify any person as a complainant. The whistleblower

protections found at 49 U.S.C. § 20109(i)(1) prohibit FRA from revealing the identity of anyone

who brings a safety complaint to FRA without that person’s written consent. However, 49

U.S.C. § 20109(i)(2) states that the U.S. Department of Transportation (DOT) will disclose to the

Attorney General the name of an employee described in 49 U.S.C. § 20109(i)(1) if the matter is

referred to the Attorney General for enforcement.

Each witness statement must contain the time, date, full name, title, and mailing address of the

person who was interviewed. Note: Bridge specialists should reference the General Manual,

Chapter 5, for witness statement guidance and an example of a witness statement form.

FRA Guidelines for Conducting Interviews

Bridge specialists should reference the General Manual, Chapter 5, for guidance in conducting

interviews.

Copies of Railroad’s Records

When necessary, the violation report must be accompanied by legible copies of the railroad’s

relevant records containing information that will provide RCC with substantiating documentation

of the violation. The violation report should give a clear understanding of how the documents

help demonstrate the violation of Federal safety regulations.

This information may be submitted in the form of duplicated copies of the railroad’s records or

through comprehensive, word-for-word extracts taken from the railroad’s records.

Violation Report Package Arrangement

When the violation report and all supporting documents have been converted into a PDF format,

these documents must be combined into one master document.

Each violation report is required to have a master file in PDF format. The filename must contain

the following information: Region, Case Type, Bridge Specialist Initials, and Violation Number

(for example: R4-TS-CLD-49.pdf). The following table lists violation case types.

Bridge Safety Standards Compliance Manual

14

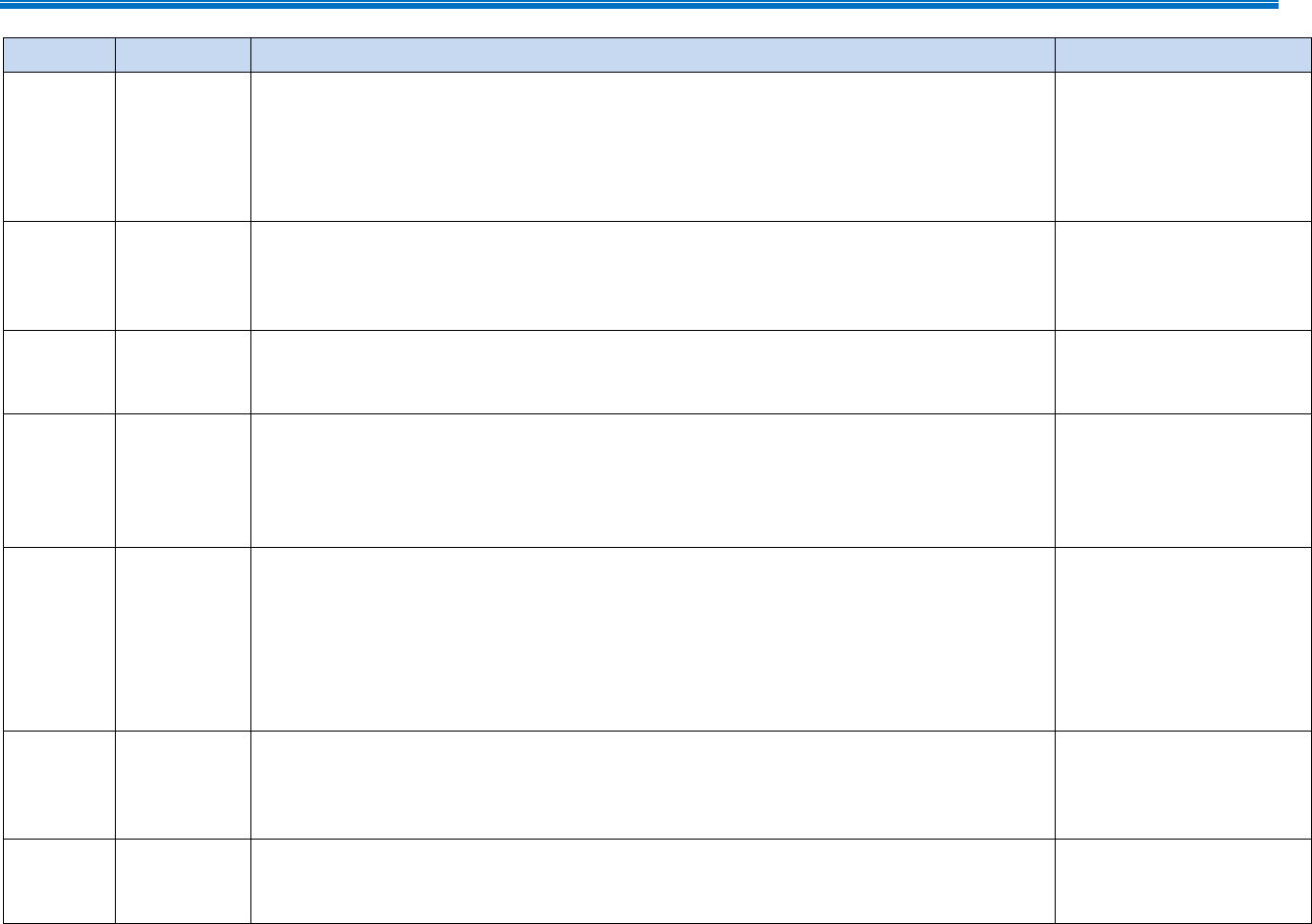

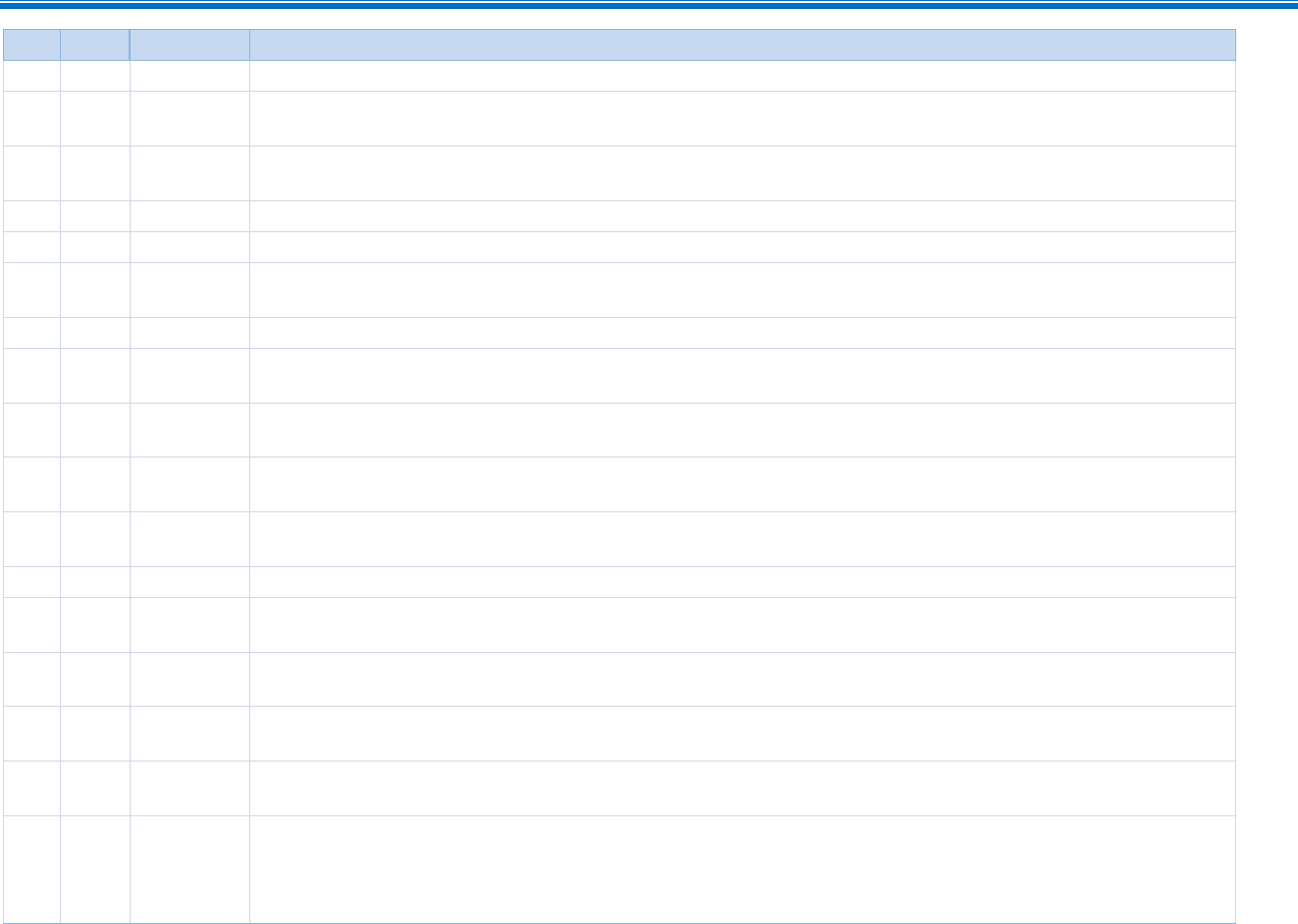

Violation Case Type List

Code

Type

AD

Alcohol and Drug Regulations

AR

Accident Reports Regulations

BSS

Bridge Safety Standards

BW

Bridge Worker Safety Standards

CC

Conductor Certification

CIS

Critical Incident Stress

EO

FRA Emergency Order

EP

Railroad Enforcement Procedures

EQ

Engineer Qualification Regulations

FCS

Freight Car Safety Standards

GC

Grade Crossing Signal Safety Regulations

GS

Safety Glazing Standards

HMT

Hazardous Materials Regulations

HS

Hours of Service Laws

HSR

Hours of Service Record Keeping Regulations

LI

Locomotive Safety Standards and Statutes

LIS

Steam Locomotive Safety Standards and Statutes

PEP

Passenger Train Emergency Preparedness Regulations

PEQ

Passenger Equipment Safety Standards

REM

Rear End Marking Device Regulations

RMM

Roadway Maintenance Machines

ROP

Railroad Operating Practices

ROR

Railroad Operating Rules

RSP

Railroad Communications Regulations

RW

Roadway Worker Protection Regulations

SA

Safety Appliance Statutes and Regulations

SI

Signal Inspection Regulations and Statutes

TH

Train Horn/Quiet Zone

TS

Track Safety Standards

The violation report package must be arranged in the following order: Violation Report,

List of Exhibits page, and exhibits in order of relevance. The requirements for these

documents are detailed as follows:

1. Violation Report – Form FRA F6180.111, including any continuation sheets: Bridge

specialists must ensure all reports in the violation report package are signed using an

authenticated electronic signature.

2. List of Exhibits: A List of Exhibits page must be created and inserted immediately after

the Form FRA F6180.111.

a. The Exhibit List must be a separate document titled “List of Exhibits.”

b. The list must not be entered in the narrative of the Violation Report (field 34).

Bridge Safety Standards Compliance Manual

15

c. All exhibits must be listed in order of relevance, and must not be numbered 1, 2, 3 or

lettered A, B, C.

3. Exhibits: Exhibits include, but are not limited to, the following:

a. Original Form FRA F6180.96, railroad copy, containing the recommendation for civil

penalty.

b. Form FRA F6180.96 for the inspection that includes the defects not recommended as

violations – railroad copy.

c. Statements of Witness, if any.

d. Copies of pertinent pages of the timetable and any other instructions that are in effect

at the time of violation.

e. Photographs, as described above. Photographs should clearly illustrate the severity of

the violation, or anything to further document why the defect is recommended for

violation. Do not include photographs if they do not show something that is

significant in supporting the violation.

f. Copies of railroad records when they are available and are part of your determination

to recommend a violation.

g. Include any other items that may further substantiate the violation.

For identification purposes, each exhibit of the violation report package must be labeled with the

bridge specialist’s initials and the violation report number (for example, JDP-55), which must be

placed in the lower right corner of each sheet.

If a bridge specialist recommends that a violation receive special handling, the bridge specialist

must submit an additional cover memo (to be signed by the Chief Engineer–Structures)

justifying the recommendation. Special handling includes a penalty above the amount shown in

the penalty schedule (Appendix B to Part 237), up to or including the aggravated maximum

penalty of $113,894, or when counts for multiple days are recommended. Please ensure that the

cover memo is included as a separate attachment from the violation report package and that the

memo provides the information and justification required by the “Enhanced Penalties” memo

dated August 31, 2016 (see General Manual, Appendix D).

The entire violation package for transmittal contains:

1. TFR – F6180.72x (transmittal document)

2. Cover letter regarding extraordinary penalties (if applicable)

3. Violation report package

Note: One and two are separate files and do not require a digital signature by the bridge

specialist.

Bridge Safety Standards Compliance Manual

16

Supervisory Review

Upon receipt of a bridge discipline inspection report, or any other report submitted by a bridge

specialist, the Chief Engineer–Structures must make a thorough review to determine that:

• The report is complete.

• It has been prepared in accordance with existing instructions.

• The type and number of inspections are consistent with the goals of FRA.

• With respect to violation reports that the bridge specialist has recommended for civil

penalty, the bridge specialist’s recommendation for prosecution demonstrates the degree

of seriousness of the violation and that, where a willful violation or an extraordinary

penalty is sought, the report and/or Chief Engineer–Structures cover memo provides the

additional justification to support a penalty beyond the ordinary level stated in the penalty

schedule for the BSS violated.

Before uploading a Form FRA F6180.111 to RISPC and sending the electronic package to

headquarters, bridge specialists are to send a draft copy to the Chief Engineer–Structures for

review. An electronic draft copy can be generated by “printing to PDF” and emailing it. The

Chief Engineer–Structures—after considering the hazard of the specific BSS violation, the

railroad’s record of accidents, and its overall compliance attitude—must indicate his or her

concurrence or non-concurrence with the bridge specialist’s estimate of the seriousness of the

violation. The Chief Engineer–Structures may also indicate edits or corrections the bridge

specialist can incorporate into the final report package.

If the Chief Engineer–Structures does not concur with the bridge specialist’s estimate of the

seriousness of the violation, the Chief Engineer–Structures must prepare a memo stating that fact

and the reasons for his or her non-concurrence and attach a copy to the violation report, with a

copy furnished to the bridge specialist. The report must then be discussed with the bridge

specialist.

Violation Report Package Distribution

Upload the Form FRA F6180.111 to RISPC within 30 days after the date of the inspection

report. After the upload process, bridge specialists must prepare an electronic master document

of the entire violation package and send it to the Chief Engineer–Structures. The violation report

package must include a copy of the inspection report and supporting documentation bookmarked

for easy reference.

After review, the Chief Engineer–Structures will electronically submit the violation report

package, including the original report, exhibits and photographs, to RCC.

The bridge specialist must number the violation narrative reports sequentially throughout his/her

career without regard to the end of any calendar or fiscal year.

Bridge Safety Standards Compliance Manual

17

Source Codes

(From April 2015 General Manual, Chapter 3)

A: Regular Inspection (All) – A periodic inspection activity conducted by Federal and/or State

railroad safety inspectors, in accordance with established procedures, to determine railroad,

shipper, consignee, contractor, and manufacturing facility compliance with Federal statutes,

rules, regulations, orders, and standards within the jurisdiction of FRA.

B: Complaint Investigation (All) – Any inspection initiated for the purpose of performing a

complaint investigation. A complaint file number must be assigned and indicated on the

inspection report when this code is used.

C: Accident Investigation (All) – Any inspection resulting from an accident/incident

investigation. An accident file number must be assigned and indicated on the inspection report

when this code is used.

D: Special Inspections or Investigations (All) – Inspections initiated for a specific reason or

purpose not otherwise identified. A file number must be assigned and indicated on the

inspection report when this code is used.

E: Waiver Investigation (All) – Inspections resulting from either investigating requests for

temporary relief from Federal regulations or validating compliance with any waiver conditions

already in effect. Use of this source code automatically requires an entry in the File Number

Field. When validating compliance with existing waiver conditions, inspectors may list all

inspection results on the same report, including results not associated with the waiver. The

Federal Register docket number, i.e., the waiver investigation file number, must be indicated in

the File Number field of the inspection report when this code is used.

F: Reserved for future use.

G: ECP Brake-Equipped Trains (MP&E) – Inspectors must complete a separate inspection

report using Source Code G, along with all related inspection activity associated with the

electronically controlled pneumatic (ECP) brake-equipped trains (e.g., 49 CFR Parts 215, 231,

and 232). Source Code G must also be used when inspection activities, such as CFR Parts 218,

223, and 229, involve ECP brake-equipped trains and equipment.

H: Nuclear Route Shipment (HM, OP, MP&E, S&TC) – Inspections of nuclear routes or

shipments as specified in the Safety Compliance Oversight Program Plan.

I: Automated Track Inspection Program (ATIP) Survey (OP, Track) – Survey while on

board specialized FRA track geometry vehicles.

J: ATIP Follow-up (Track) – Field inspections to determine railroad remedial action resulting

from noncompliance identified by specialized FRA track geometry vehicles.

K: Reserved for future use.

L: Regular Inspection of a STRACNET Segment (Track).

M: Special Investigation or Assessment on STRACNET Segments (Track).

N: ATIP Survey (Using Test Car) on STRACNET Segments (Track).

O: RS&I Investigation (S&TC) – Inspections performed while investigating a request of relief

Bridge Safety Standards Compliance Manual

18

from the requirements of the rules, standards, and instructions (RS&I) contained in 49 CFR Part

236. A file number must be assigned and indicated on the inspection report when this code is

used.

P: BS-AP Investigation (S&TC) – Inspections performed while investigating a request for

discontinuance or material modification of a signal or train control system (block signal

application). A file number must be assigned and indicated on the inspection report when this

code is used.

Q: False Proceed Investigation (S&TC) – Inspections performed while investigating a false

proceed signal occurrence. A file number must be assigned and indicated on the inspection

report when this code is used.

R: Re-inspection (All) – Inspection activity carried out to examine, monitor, or further develop

previously conducted work. Inspectors must use good judgment when deciding the appropriate

interval for the re-inspection, taking into consideration factors such as the inherent seriousness of

the noncompliance and the railroad’s general level of current compliance as revealed by the

original inspection as a whole. S&TC and Track inspectors must also be governed by discipline-

specific guidelines. The File Number field must contain the inspector identification and the

previous inspection report number.

S: Reserved for future use.

T: Reserved for future use.

U: Waiver Inspection (Follow-up).

V: Inspection of or at Manufacturers Facility (MP&E/HM).

W: Reserved for future use.

X: Activation Failure (Signal) – Inspections performed while investigating an activation failure

occurrence. A file number must be assigned and indicated on the inspection report when this

code is used.

Y: Reserved for future use.

Z: Outbound Extended Haul Trains (MP&E)

Bridge Safety Standards Compliance Manual

19

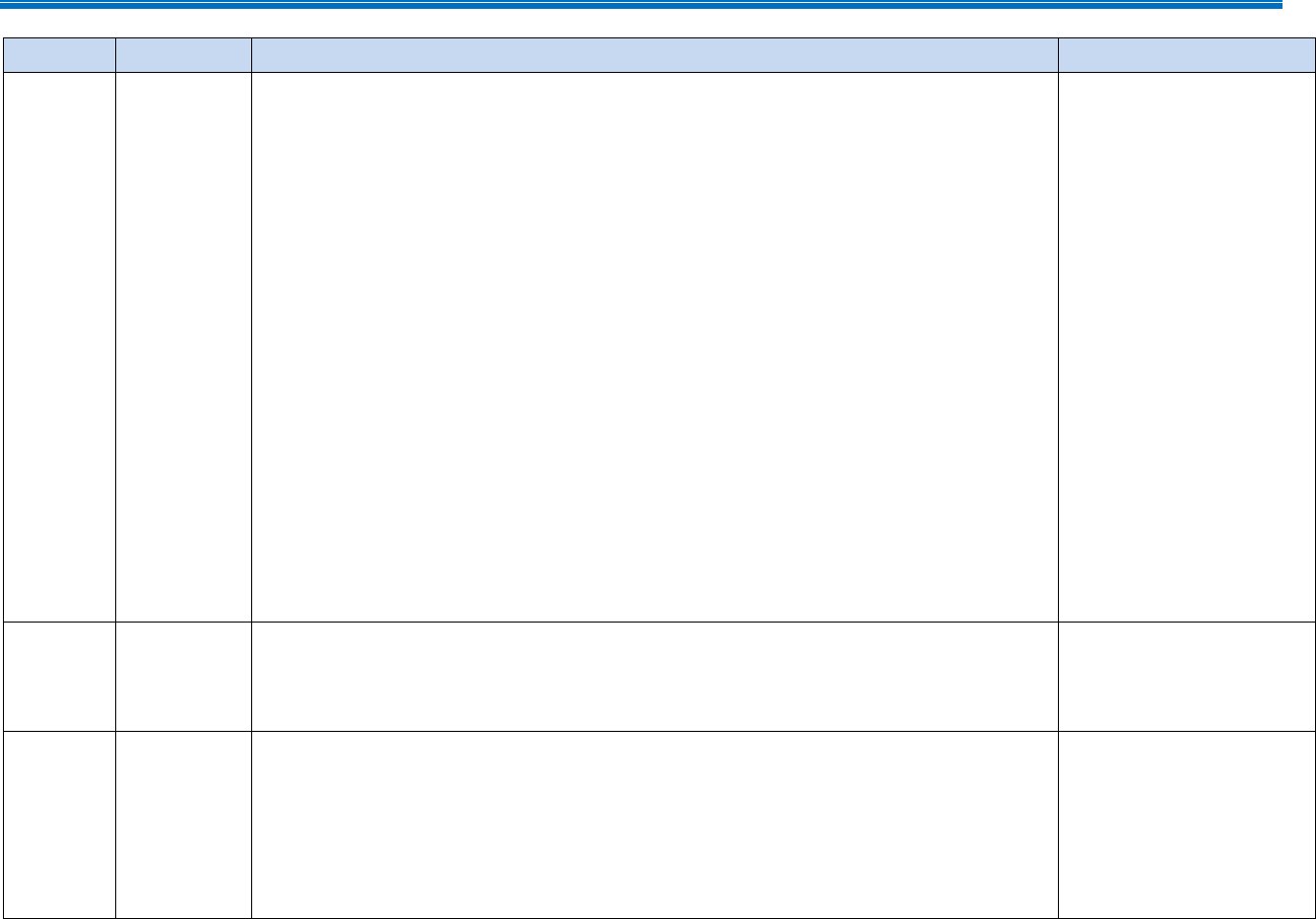

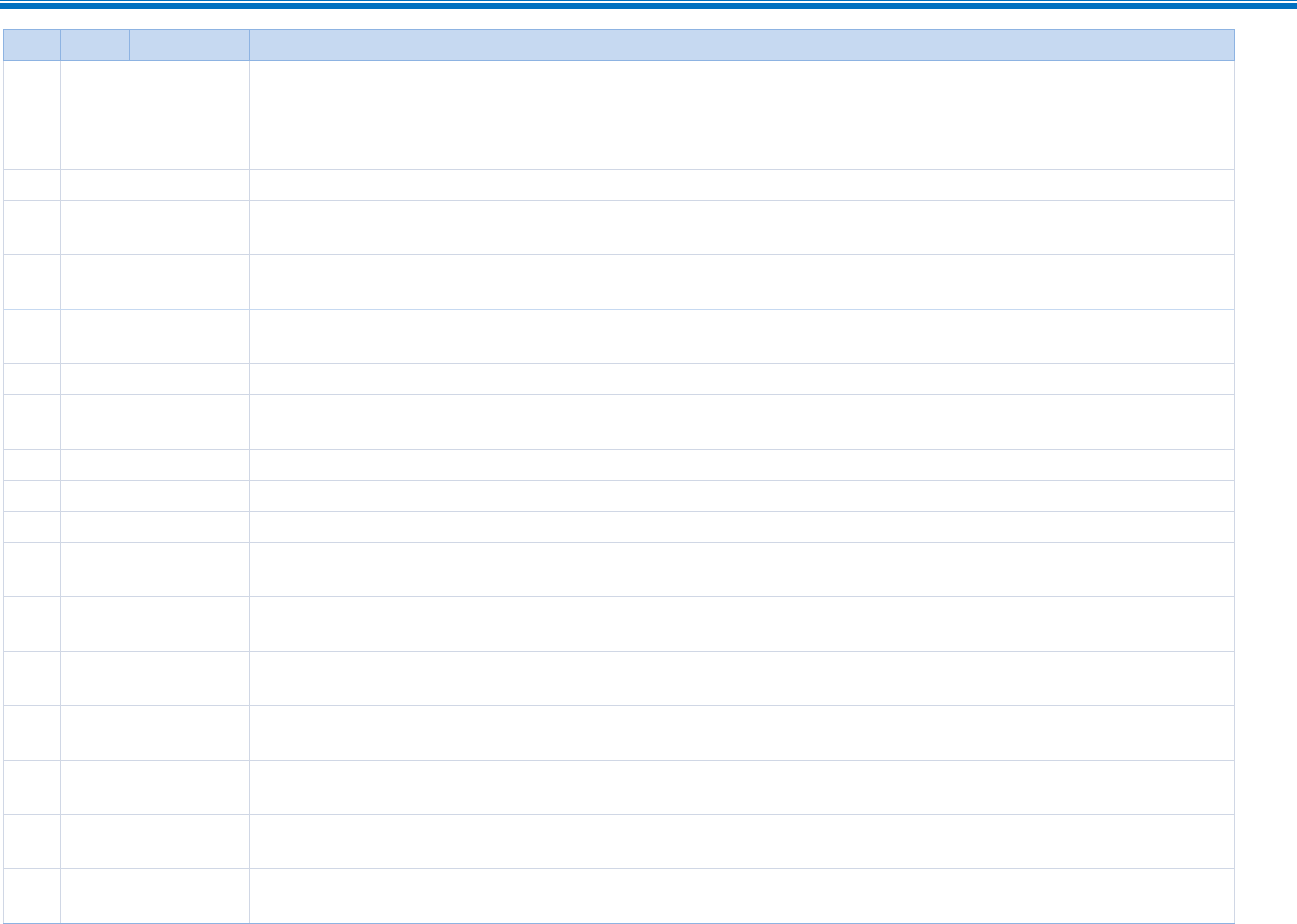

Multidiscipline Activity Code Table of Definitions

(The table is based on the RISPC Database Revised on January 17, 2012)

Activit

y

Discipline Definition Comments

174A H, M

General Requirements – The purpose of this inspection is to determine compliance with §§

174.3, 174.5, 174.9, 174.14, 174.16, and 174.50. This code is to be used for railroad facility

inspections. Record one unit for the inspection of each car transporting hazardous materials.

174B H, O

General Operating Requirements – The purpose of this inspection is to review a train crew’s

documentation for each rail car containing hazardous material, including any changes in

placement of the car. The inspection should include determining compliance with the basic

hazardous materials shipping paper descriptions as required in § 174.26. Record one unit for

each train consist inspected, and one subunit for each inspection of the basic shipping paper

description of each car containing hazardous materials.

Note 1: Inspectors must use Activity Code TPLH to record inspections associated with train

placement requirements.

Note 2: Inspectors must use this code instead of Code 172C when inspecting shipping

papers specific to a particular train.

209 ALL

Remedial Action – The purpose of this inspection is to report a railroad that has not complied

with a requirement to provide a remedial action as noted in a previous inspection report.

Record one unit for each remedial action not in compliance.

(See General Manual for additional guidance).

215D H, O, S, T

Freight Car Mechanical Inspection – The purpose of this inspection is for any inspector

other than an MPE inspector to determine compliance with Part 215, including Appendix D.

The inspection includes those performed by an FRA inspector or when an FRA inspector

observes railroad employees performing this inspection. MPE inspectors should reference

Activity Code 215. Record one unit for each freight car inspected or observed inspected for

compliance with § 215. For articulated cars, count each platform as one unit.

Note 1: HM and OP inspectors should use the Activity Code HM for ALL of their Part 215

inspections.

Note 2: Properly stenciled maintenance-of-way equipment is exempt from Part 215.305(b).

Bridge Safety Standards Compliance Manual

20

Activit

y

Discipline Definition Comments

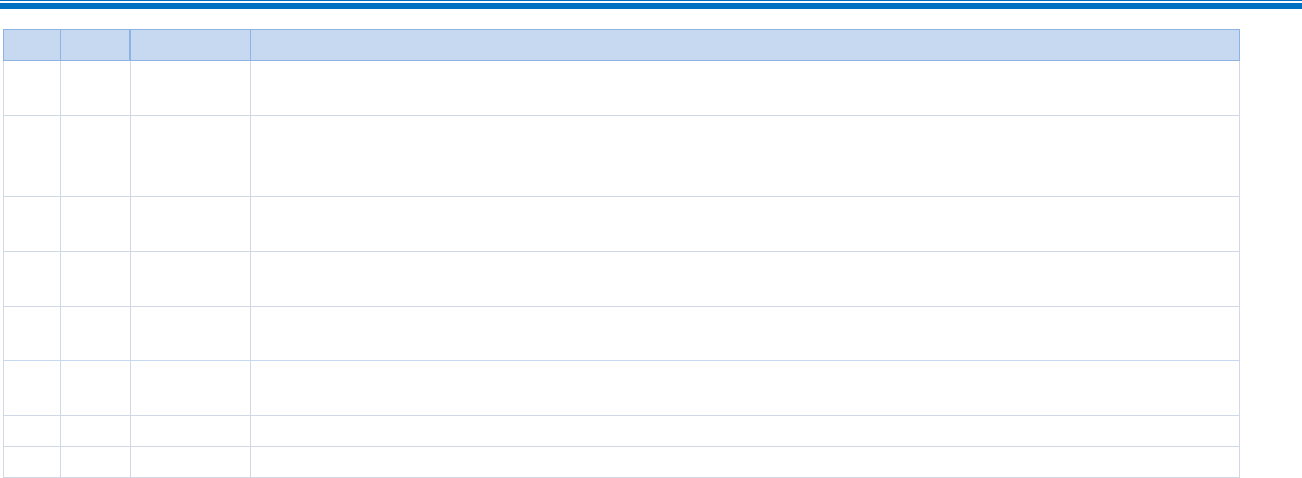

217E ALL

Emergency Order – The purpose of this inspection is to determine compliance with a current

Emergency Order. Record each unit and subunit as directed by the unique instructions

issued by FRA Headquarters regarding each specific Emergency Order. Inspectors must

thoroughly explain the inspection in the inspection report’s narrative.

217O ALL

Other Operations Obs

ervations – The purpose of this inspection is to observe railroad

employees of any craft performing duties regarding railroad operating rules (ROR) and railroad

safety rules (RSR). It will include all related RORs, RSRs, railroad bulletins, and any written

railroad policy not otherwise covered in Federal regulations. Noncompliance will be recorded

as a non-FRA defect under this activity code. Record one unit for an entire yard or equivalent

facility monitored, and one subunit for each crewmember, yardmaster, contractor, track

employee, mechani

cal employee, si

gnal maintainer, etc., that the inspector continually

observed a sufficient amount of time to determine compliance or noncompliance.

Note: Unlike noncompliance with Federal regulations, it is FRA policy that inspectors provide

information recorded under this activity code regarding noncompliance of an ROR/RSR,

without identifying the noncompliant employee by name, in the Federal inspection report.

See the General Manual for further explanation.

Example 1: An FRA Track inspector observes a 20-person section gang working for

approximately 45 minutes when the inspector observes a track employee sitting on the rail.

The FRA inspector intervenes by addressing the employee’s noncompliance with an RSR, and

then discusses the noncompliance with the employee’s supervisor. The inspection report will

include the recording of one occurrence of a non-FRA defect for a track employee’s failure to

comply with the specific RSR that prohibits employees from sitting on a rail. The inspector will

record the inspection as one unit and 20 subunits.

Example 2: An FRA MPE inspector observes four persons working on a railroad car with

proper Blue Signal Protection for approximately 10 minutes when the inspector observes one

of the workers perform a task while not wearing the required protective equipment. The FRA

inspector intervenes by addressing the employee’s noncompliance with an RSR by

discussing it with the employee’s supervisor. The inspection report will include the recording

of a non-FRA defect for a car shop employee’s failure to comply with the specific RSR that

prohibits performing the task without the proper protective equipment. The inspector will

record the inspection as one unit and four subunits.

218C O, S, T

Camp Car Protection - The purpose of this inspection is to determine compliance with camp

car protection. Record one unit for each track inspected that requires camp car protection.

Bridge Safety Standards Compliance Manual

21

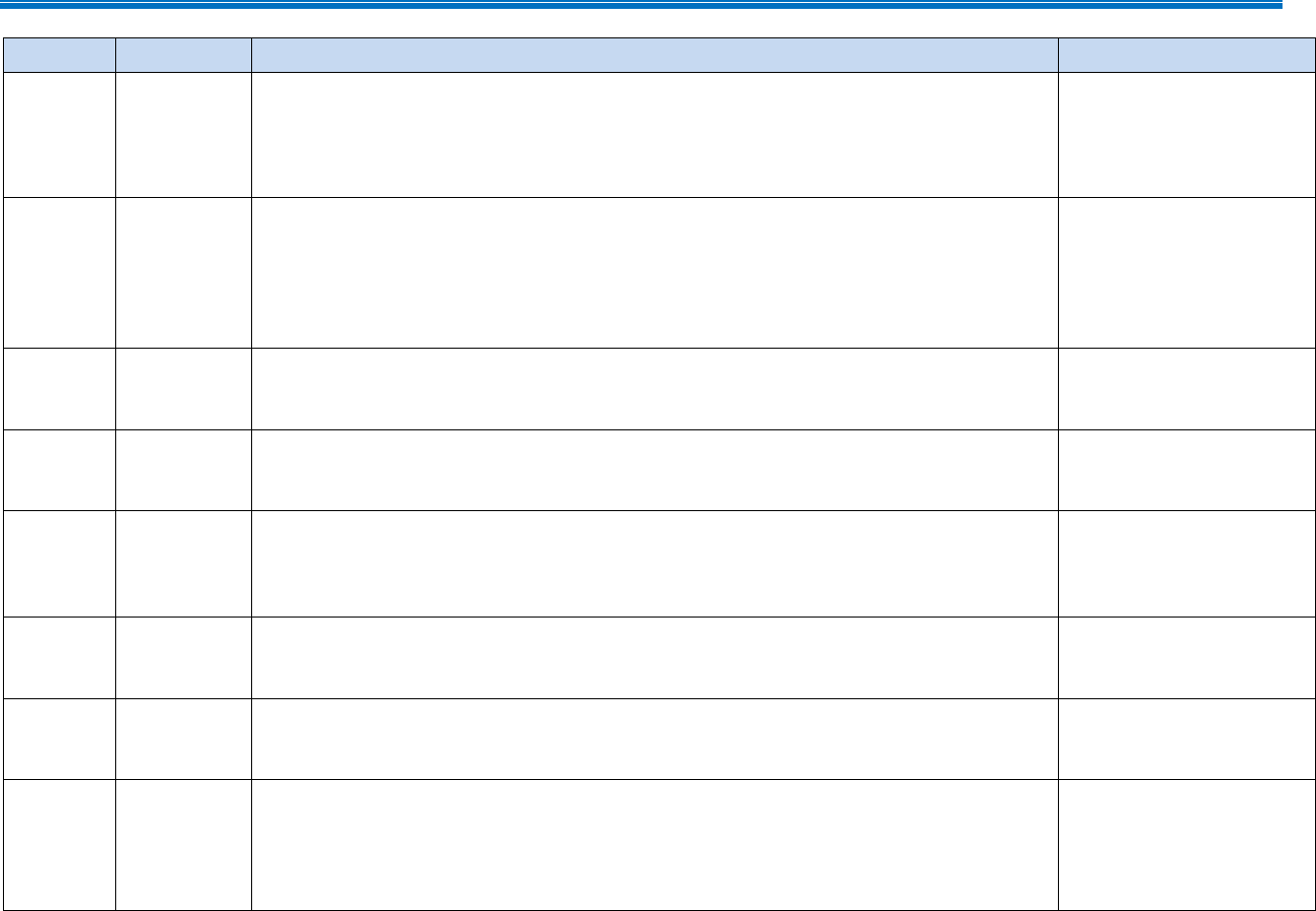

Activit

y

Discipline Definition Comments

218M M, O

Blue Signal Protection on Main or Other than Main Track – The purpose of this inspection

is to determine if the protection provided railroad employees requiring Blue Signal Protection is

in accordance with §§ 218.25, 218.27, and 218.30. Record one unit for each track that

requires Blue Signal Protection. If the track requiring Blue Signal Protection has more than one

train or cut of cars requiring protection, record one unit for the entire track.

Regarding inspecting compliance with Blue Signal regulations involving a remotely controlled

switch, record one unit for all associated recordkeeping requirements at that location, and one

subunit for each track associated with those records.

Note 1: Exc

ept for stub tracks, both ends of the track must be inspected for

compliance with the Blue Signal regulations.

Note 2: There is a drop-down FRA observation code inspectors may use in lieu of writing a

comment when there are not any exceptions noted.

218O ALL

Part 218, Subpart F – The purpose of this inspection is to determine a railroad’s compliance

with Part 218 Subpart F, including the requirement for a railroad to have complying railroad

operating rules as indicated in the regulation. Record one unit for each day, or partial day,

spent

reviewing relevant railroad rules, or for each yard or equivalent facility monitored. Record one

subunit for each crewmember, yardmaster, contractor, track employee, mechanical employee,

signal maintainer, etc., that the inspector continually observed for a sufficient amount of time to

determine compliance or noncompliance.

Note: It is FRA policy that inspectors provide information regarding incidents recorded under

this activity code as noncompliance of a Federal regulation. It will include identifying the

noncompliant individual by name in the inspection report. See the General Manual for a

further explanation.

Example 1: An FRA Track inspector observes a 12-person section gang working for

approximately 45 minutes when the inspector observes a track employee throwing a switch

with equipment in the foul of the switch. The FRA inspector intervenes by addressing the

employee’s noncompliance with Part 218 Subpart F, and then discusses the noncompliance

with the employee’s supervisor. The inspection report will include the recording of the

noncompliance for the track employee’s failure to comply with Part 218, Subpart F, and the

name of the employee in noncompliance. The inspector will record the inspection as one unit

and 12 subunits.

Example 2: An FRA MPE inspector observes six persons switching railcars in a car shop

for approximately 10 minutes when the inspector observes one of the workers fails to

properly protect a shoving movement. The FRA inspector intervenes by addressing the

Bridge Safety Standards Compliance Manual

22

Activit

y

Discipline Definition Comments

employee’s noncompliance with Part 218 Subpart F, and then discusses the noncompliance

with the employee’s supervisor. The inspection report will include the recording of the

noncompliance for the car shop employee’s failure to comply with the Part 218 Subpart F,

and the name of the employee in noncompliance. The inspector will record the inspection

as one unit and six subunits.

Example 3: An inspector reviews the railroad rules to determine if they are in compliance with

the requirements set forth regarding railroad equipment in the foul and operating switches. The

inspection report will include the recording of one unit for this inspection and will also reference

the precise railroad rules, or lack thereof, in the inspection report’s narrative.

218S M, O

Blue Signal Protection Locomotive or Car Shops – The purpose of this inspection is to

determine compliance with regulations requiring Blue Signal Protection in a locomotive

servicing track area, a car shop repair track area, or a track that has been designated as a

repair track or expedite track. Record one unit for each area inspected.

If § 218.29(c), Alternative methods of protection, applied in a car shop repair track area or a

locomotive servicing track area, one unit is recorded for the entire area, regardless of the

number of tracks in the area or the number of cars or locomotives on those tracks.

Note: There is a drop-down FRA observation code inspectors may use in lieu of writing a

comment when there are not any exceptions noted.

221 M, O

Rear End Markers – The purpose of this inspection is to monitor compliance with Part 221.

This activity code should not be used when inspecting an End of Train (EOT) device under

Part 232. Record one unit for each train, locomotive (including distributed power units

(DPUs)), or caboose inspected for compliance.

The inspection of each rear end marking device in rooms or locations where rear end marking

devices are stored and/or recharged and maintained is one unit. Each rear end marker ID must

be recorded in the line item along with the appropriate observation. Individual marking devices

that are not attached to trains or in storage areas not subject to service are not recorded as a

unit.

Note: There is a drop-down FRA observation code inspectors may use in lieu of writing a

comment when there are not any exceptions noted.

227N IH

227N - Occupational Noise Exposure - The purpose of this inspection is to determine

compliance with Part 227 regarding occupational noise exposure in the locomotive cab. It

will include audiometric test records, employee noise exposure monitoring plan and

monitoring records, cab noise monitoring records, postings of monitoring results, training

plans and records, or interviewing persons regarding noise exposure. Record one unit for

Bridge Safety Standards Compliance Manual

23

Activit

y

Discipline Definition Comments

each day or partial day of an inspection and one subunit for each Part 227 record reviewed.

Note: This activity may only be claimed when accompanied by a member of the

Industrial Hygiene staff.

228 O, S

Hours of Service Records Inspection – determine if Hours of Service (HOS) records are in

compliance with Part 228. Record one unit for each day or partial day of inspection, and one

subunit for each HOS record reviewed. This activity code includes any examination of HOS

logs, HOS report forms, HOS documents, interviewing employees regarding HOS, and any

other HOS records review activity. This activity code is not used to document an employee

exceeding the HOS.

Note: Reports taking exception to an employee exceeding the hours of service should not be

recorded under this activity code; please reference the proper activity code associated with the

employee’s type of work or discipline. Example: Activity Code 228P, 211, or HSL.

228C O, S

Construction of Employee Sleeping Quarters – The purpose of this inspection is to determine

compliance with Part 228, Subpart C. Record one unit for each day, or partial day, spent

reviewing relevant facilities regarding Part 228, Subpart C.

229X H, O

Locomotive Inspection in Operations – The purpose of this inspection is for any inspector,

other than an MP&E inspector, to determine a railroad’s compliance with Part 229. Record

one unit for any locomotive inspected. The inspection may include, but is not limited to, the

locomotive daily inspection, any passageway tripping hazards, cab sanitation, cab lighting,

speed indicator check, etc.

232E M, O

End of Trai

n Device – The purpose of this inspection is to inspect an End of Train (EOT)

device for compliance with Part 232. The inspection must include verifying that the information

on the calibration sticker is legible, and that it contains the date, name of person, and location

of the last calibration. This activity also includes comparing the quantitative values between

the front and rear unit, as well as the ability of the rear unit to effect an emergency application

in response to an emergency application initiated from the front unit. Record one unit for each

EOT i

nspected or

observed for compliance.

Note: This act

ivity code will be used when citing defects on the Head End Device

(HED) associated with the EOT device

232O H, O, S, T

Freight Train Brake Test Observation – The purpose of this inspection is for any inspector,

other than an MP&E inspector, to determine compliance with Part 232 not covered in activity

Bridge Safety Standards Compliance Manual

24

Activit

y

Discipline Definition Comments

code 232E or 232X. It includes any airbrake test required by Part 232. Airbrake test inspections

should include in the narrative of the inspection report if the inspector was observing or

accompanying a railroad employee or contractor employee performing the airbrake test. Record

one unit for each observation or inspection, and one subunit for each railcar involved.

232X M, O

Securement of Locomotive and Cars – The purpose of this inspection is to determine if

railroad equipment is in compliance with § 232.103(n). Record units as follows:

1. Record one unit for an inspection of unattended equipment that consists of a single

locomotive or locomotive consist, either attached to cars or not. This inspection includes

determining compliance with the requirements for throttle position, status of the reverse

lever, position of the generator field switch, status of the independent brakes, position of

the isolation switch and handbrake, and position of the automatic brake valve.

2. Record one unit for an inspection of unattended equipment NOT attached to

locomotives that are required to be secured under this regulation. This unit includes

inspections for bottled air.

Note 1: If a train is separated to avoid blocking any type of crossing, it should have each

section of the equipment recorded as a separate unit.

Note 2: The inspection report that records a defect or recommended violation identified

should clearly state the number of handbrakes found to be applied, the number of

handbrakes required to be applied, and the current operating rule in place that indicates the

precise number of handbrakes required to be applied.

Note 3: This in

spection also includes an inspector reviewing railroad rules for compliance

of this part.

Example: If 30 unattended railcars are found on a track that is required to have seven hand

brakes applied but the inspection reveals that only one handbrake is applied, it will be recorded

as one unit with one occurrence for the failure to have the other six handbrakes applied.

238O H, O, S, T Passenger Equipment Inspection (Partial) – The purpose of this inspection is for any

inspector, other than an MP&E inspector, to determine compliance with Part 238 that is not

covered in activity codes 232X or 238T. Record one unit for each inspection and a subunit for

each passenger car inspected.

Bridge Safety Standards Compliance Manual

25

Activit

y

Discipline Definition Comments

238T M, O

Passenger Train Brake Test Observation – The purpose of this inspection is to document

an observation of a passenger train airbrake test, excluding tourist equipment. Record one

unit for each entire brake test observed for compliance with Part 238, and one subunit for

each railroad record associated with the Class I air brake test.

Note: There is a drop-down FRA observation code inspectors may use in lieu of writing a

comment when there are not any exceptions noted.

238X M, O

Passenger Equipment Securement – The purpose of this inspection is to determine if

passenger or commuter equipment is properly secured (excluding tourist equipment).

Record one unit for each train, whether or not a locomotive is attached.

BPL H, M

Bulk Packages (Applies to bulk packagings, including Intermodal Portable Tanks and

Intermediate Bulk Containers, other than tank cars) – Record one unit for each limited,

ground-level inspection of both sides of the bulk package and does not include a top-level

inspection. This activity code may only be used when assessing compliance with §§

172.302, 172.304, 173.326, 172.502, 172.516, and 174.50.

Note 1: Use TCL & TCT codes to record tank car inspections.

BWS S, T Bridge Worker Safety – An inspection concerning Part 214, Subpart B, Bridge Worker Safety

Standards. Record one unit for each bridge gang or work group, and one subunit for each

member of the gang or work group.

FCL H, M

Inspection of Freight Containers, General Handling and Loading

Requirements – The purpose of the inspection includes inspecting the exterior of freight

containers for markings, placards, structural integrity, and securement to the railcar. Record o

ne

unit for each freight container inspected.

Note 1: Use BPL & BPT codes to record intermodal tank inspections.

NOIR ALL

Noise Test Records – The purpose of this inspection is to document a review of a

locomotive’s noise testing session or a locomotive’s noise testing record. Record one unit for

each locomotive’s noise testing session monitored and/or all noise testing records associated

with that locomotive tested.

Example 1: A short line railroad has three records on file documenting a locomotive horn test

performed on locomotive SP 1234. Record one unit for the examination of all three records.

Example 2: A short line railroad has three records on file documenting a locomotive horn test

Bridge Safety Standards Compliance Manual

26