AN ABSTRACT OF THE THESIS OF

Christopher A. Letchworth for the degree of Master of Science in Food Science and Technology presented

on April, 24 2020.

Title: Reduction of Salmonella spp. on In-shell Hazelnuts Using Continuous Steam Blanching and Prevalence

of Salmonella spp. on In-shell Oregon Hazelnuts.

Abstract approved:

Robert J. McGorrin

Tree nuts have been implicated in a number of foodborne outbreaks and recalls in recent years linked to

enteric pathogens, particularly Salmonella. Therefore, prior to distribution and marketing, it is necessary to

understand the biological risks associated with the consumption of tree nuts and to find effective methods to

inactivate foodborne pathogens. Steam treatment processes have been validated for use on California

almonds, but little research has been conducted for in-shell hazelnuts. Hazelnuts grown in Oregon were

recalled nearly annually from 2009 to 2017 and were implicated in an outbreak of E. coli O157:H7 that

sickened 10 people in the Midwest and Canada in 2011 (Miller et al. 2014). In 2017, an outbreak of Salmonella

Typhirium sickened 5 people and was traced to an 80-acre Oregon farm and nursery that sold between 32,000

to 48,000 pounds of raw in-shell hazelnuts directly to consumers from a road-side stand (Yada et al. 2019).

To help characterize the biological risk of in-shell hazelnuts, we conducted a prevalence and amounts survey

of Salmonella on in-shell hazelnuts grown in Oregon over two harvest years (2013-2014). In a separate study,

we developed a steam treatment process that inactivates a 5-log reduction of Salmonella spp. on the surface of

in-shell hazelnuts with minimal impact on final product quality.

For the Salmonella prevalence study, raw, green-dried in-shell hazelnut samples (n = 472) were collected by six

of the largest hazelnut handlers in Oregon’s Willamette Valley and tested for the presence of Salmonella spp.

using a modified method from the Food and Drug Administration’s (FDA) Bacteriological Analytical Manual

(BAM). In-shell hazelnut samples (375 g) were enriched in 1:10 (w/v) lactose broth followed by selective

enrichment in Rappaport-Vassiliadis Broth (RV) and Tetrathionate Broth (TT). Selective enrichments were

streaked for isolation onto Hektoen Enteric (HE) and Xylose Lysine Desoxycholate (XLD) Agars. Suspected

colonies displaying Salmonella spp. morphology were confirmed on CHROMagar Salmonella Plus. A most-

probable-number (MPN) method (3 x 333, 33.3, 3.3 g) using the same cultural steps as the initial testing was

used to determine Salmonella population levels on naturally-contaminated in-shell hazelnuts. The prevalence

of Salmonella spp. by year was 21.7% (55/254) and 46.8% (102/218) for 2013 and 2014, respectively.

Salmonella population levels ranged from 0.092 to 30.7 MPN/100 g, with an average of 2.6 MPN/100 g.

These data will help support risk assessment strategies for the Oregon hazelnut industry.

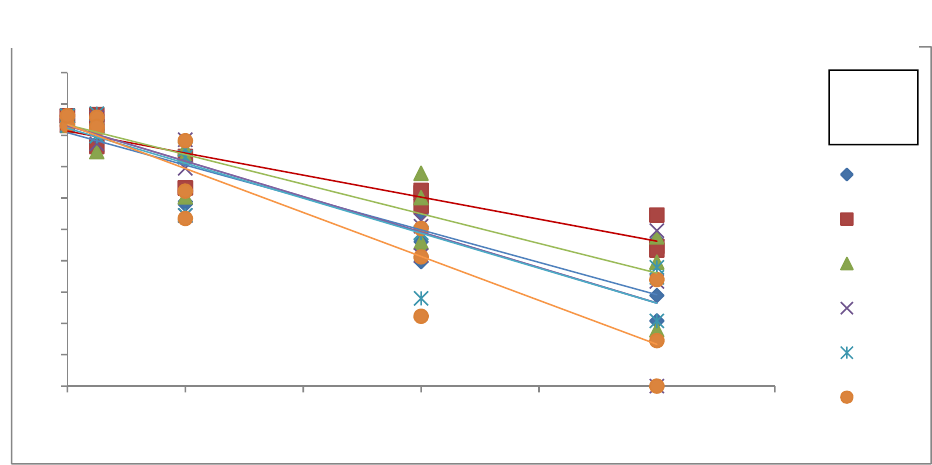

In our second study, we evaluated the efficacy of steam blanching on the reduction of Salmonella spp. on the

surface of in-shell hazelnuts as a potential thermal postharvest treatment for hazelnuts. A pilot-scale steam

blancher was used to deliver a continuous steam treatment at atmospheric pressure. In-shell hazelnuts were

inoculated (~8.5 log CFU/g) with a five-strain Salmonella spp. cocktail and exposed to steam (88

C) for 15 s,

1, 3, 5, and 10 min. Following steam treatment, hazelnut samples were transferred to 0.1% peptone water

(24

C), hand agitated 1 min, serially diluted, plated on Hektoen Enteric agar and incubated at 37

C for 24 h.

D-values (0.82 to 1.53 min) were calculated based on plate counts. Salmonella spp. could not be recovered by

enrichment after hazelnuts inoculated at 5 log CFU/g were treated with steam at 88

C for 10 min. These

data will be useful when developing validated postharvest steam treatments for the hazelnut industry.

©Copyright by Christopher A. Letchworth

April 24, 2020

All Rights Reserved

Reduction of Salmonella spp. on In-shell Hazelnuts Using Continuous Steam Blanching and Prevalence of

Salmonella spp. on In-shell Oregon Hazelnuts

By

Christopher A. Letchworth

A THESIS

submitted to

Oregon State University

in partial fulfillment of

the requirements for the

degree of

Master of Science

Presented April 24, 2020

Commencement June 2020

Master of Science thesis of Christopher A. Letchworth, presented on April 24, 2020

APPROVED:

Major Professor, representing Food Science and Technology

Head of the Department of Food Science and Technology

Dean of the Graduate School

I understand that my thesis will become part of the permanent collection of Oregon State University libraries.

My signature below authorizes release of my thesis to any reader upon request.

Christopher A. Letchworth, Author

ACKNOWLEDGEMENTS

I would like to express my deepest gratitude and appreciation to my advisor, Dr. Robert McGorrin, for giving

me the opportunity to learn and grow as a scientist as well an individual. His continual support of my

professional and personal goals, along with his fundamental understanding of food science and extensive

knowledge of food industry needs, has helped make me a better scientist and person. It has been an honor

and privilege conducting research under his guidance.

I would also like to acknowledge the support of my other thesis committee members: Drs. Lisbeth Goddik, Si

Hong Park, and Bill Braunworth. I wish to thank them for generously offering their time and expertise. I

appreciate their assistance, valuable advice and guidance.

I would like to also express my sincerest appreciation to the Oregon Hazelnut Marketing Board, including

Polly Owen and Michael Klein for providing funding and resources for this research. The generous support

provided by the Hazelnut Marketing Board helped make this research possible.

I am also extremely grateful for the continual support I received from family and friends during my research.

I would like to thank my parents George and Frances Letchworth for their continued support of my

educational and personal goals, as well as my amazing friends in the lab and the FST department for their

assistance and encouragement over the last few years.

TABLE OF CONTENTS

Page

1. INTRODUCTION……….……………………………………………………………………………. 1

2. LITERATURE REVIEW……………………………………………………………………………..... 2

2.1 HAZELNUTS………………...……………………………………………………………… 2

2.1.1 Hazelnuts ……………………………………………………………………………... 2

2.1.2 Geographic Distribution………..……………………………………………………....2

2.1.3 Growth and Production. .………...…………………………………………………… 3

2.1.4 Oregon Hazelnut Industry ……………………………………………………………. 4

2.1.5 Oregon Hazelnut Varieties..…………………………………………………………… 4

2.2 OUTBREAKS AND RECALLS ASSOCIATED WITH TREE NUTS….…………………... 5

2.2.1 Mandatory Pasteurization of Almonds……………………..……...………………….... 7

2.2.2 Salmonella Risk Assessment for Tree Nuts………………….………………………….. 7

2.2.3 Prevalence of Foodborne Pathogens on Tree Nuts……….………..………………….. 8

2.3 VALIDATED POSTHARVEST TREATMENTS……………...…………………………... 11

2.3.1 Propylene Oxide ……………………………………………………………………...11

2.3.2 Oil Roasting .……………….………………………………………………………. 13

2.3.3 Dry Roasting…...…………………………………………………………………….. 14

2.3.4 Steam Treatment……………………………...……………………………………… 14

2.3.4.1 Proprietary Steam Technologies……………………….…………………... 15

2.3.5 Hot Water Blanching………………………………..………………………………... 16

2.4 POTENTIAL SOURCES OF CONTAMINATION ………………………….……………17

2.5 PATHOGENS ASSOCIATED WITH TREE NUTS…..…………………………………... 18

2.5.1 Salmonella spp . ……………………………………………………………………… 18

2.5.2 Escherichia coli O157:H7 …………………………………………………………......... 18

2.6 PERSISTENCE AND SURVIVAL OF PATHOGENS IN TREE NUTS AND OTHER

LOW-MOISTURE FOODS………………………………………………………………...19

2.7 REFERENCES……………………………………………………………………………... 20

3. PREVALENCE AND LEVELS OF SALMONELLA SPP. ON IN-SHELL OREGON

HAZELNUTS OVER THE 2013 AND 2014 HARVESTS………………………………………….. 24

3.1 ABSTRACT ……………………………………………………………………………….... 25

3.2 INTRODUCTION ………………………………………………………………………… 26

3.3 MATERIALS AND METHODS.…………………………………………………………... 28

3.3.1 Hazelnut Sample Collection …………………………………………………………. 28

3.3.2 Salmonella spp. Analysis………………………………………………………………..28

3.3.2.1 Presence/Absence………………………………………………………….28

3.3.2.2 Most Probable Number (MPN)…………………………………………… 29

3.4 RESULTS AND DISCUSSION …………………………………………………………….30

3.4.1 Prevalence of Salmonella spp. in Hazelnuts ……………………………………………30

3.4.2 Concentration of Salmonella spp. in Hazelnuts ……………………………………….. 31

3.5 ACKNOWLEDGEMENTS………………………………………………………………... 35

3.6 REFERENCES……………………………………………………………………………... 36

TABLE OF CONTENTS (Continued)

Page

4. REDUCTION OF SALMONELLA SPP. ON IN-SHELL HAZELNUTS USING CONTINUOUS

STEAM BLANCHING AND THE IMPACT ON PRODUCT QUALITY AND SENSORY

CHARACTERISTICS………………………………………………..………… ……………………... 38

4.1 ABSTRACT………………………………………………………………………………… 39

4.2 INTRODUCTION ………………………………………………………………………… 39

4.3 MATERIALS AND METHODS……………………………………………………………42

4.3.1 Hazelnuts…………………………………………………………………………….. 42

4.3.2 Preparation of Inoculum…………………………………………………………........ 42

4.3.3 Immersion Inoculation Method.….……………………………………………...……43

4.3.4 Spot Inoculation Method…………..………………………………………………… 43

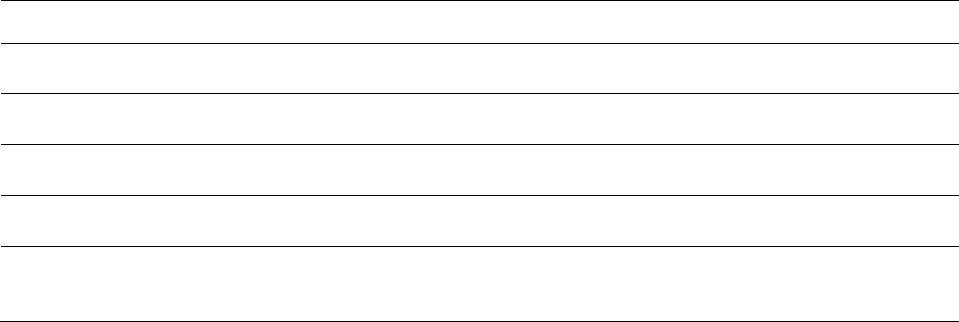

4.3.5 Description of Pilot-Scale Steam Blancher …………………………………………... 44

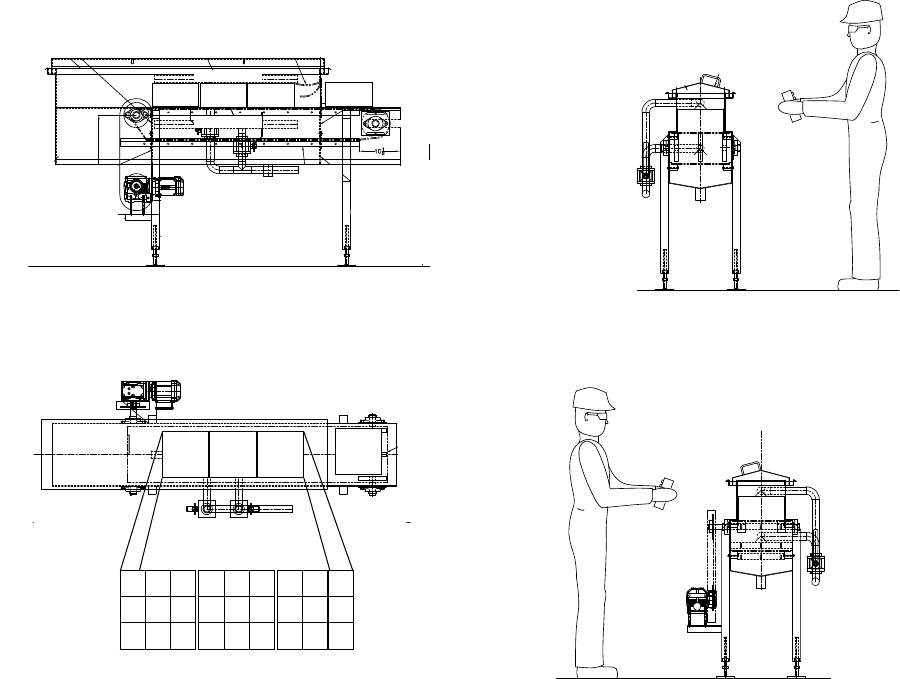

4.3.6 Sample Preparation and Arrangement………………………………………………... 46

4.3.7 Steam Treatments……………………………………………………………………. 47

4.3.8 Microbial Analysis……………………………………………………………………. 47

4.3.9 Sensory Analysis…………………………………………………………………........ 48

4.3.10 Statistical Analysis…………………………………………………………………... 49

4.4 RESULTS……………………………………………………………………………………49

4.4.1 Reduction of Salmonella spp. After Steam Treatment…………………………………. 49

4.4.2 Temperature Profile of Steam Blancher Chamber During Steam Treatments….……... 52

4.4.3 Endpoint Determination – Verification of 5-log Reduction…….……………………. 53

4.4.3.1 Immersion Inoculated Salmonella spp. Cells………………………………... 53

4.4.3.2 Spot Inoculated Salmonella spp. Cells…………………..………..…………. 54

4.4.5 Sensory Analysis – Attributes Acceptability Test and Triangle Difference Test………. 56

4.5 DISCUSSION………………...……………………………………………………………...58

4.5.1 Steam Treatment Efficacy – This Study Compared to Previous Studies….….………... 58

4.5.2 Variability of Pilot-Scale Steam Treatment Efficacy at Shorter Treatment Times.……..59

4.5.3 Predicted Model versus Verification Results…………………………………………. 60

4.5.4 Physical Characteristics of the Nut and Comparison of Inoculation Methods….……...60

4.5.5 Sublethally Injured Foodborne Pathogens………………….…………….…………... 61

4.6 CONCLUSION……………………………….……………………………………………. 62

4.7 ACKNOWLEDGEMENTS….…………….….………………………...…………………. 62

4.8 REFERENCES….……………….…………….……………………………………..…….. 63

5. OVERALL CONCLUSION…….……….…….……………………………………………………... 65

LIST OF FIGURES

Figure Page

4.1 Pilot-scale steam blancher and sample configuration for in-shell hazelnut treatments.……………… 45

4.2 Sample layout blancher: location of catch compartments used for treatment validation…………….. 47

4.3 Survival of Salmonella spp. on immersion inoculated hazelnuts after exposure to steam at 88

°

C……...52

4.4 Ratio of Salmonella positive samples after enrichment……….……………………………………….53

LIST OF TABLES

TABLE Page

2.1 Outbreaks of foodborne illness associated with the consumption of tree nuts…....………………….. 6

2.2 Prevalence and levels of Salmonella on naturally-contaminated tree nuts in North America....................10

3.1 Prevalence and amounts of Salmonella spp. on in-shell hazelnuts……………...…….…........................ 34

3.2 Recovery frequency of Salmonella during MPN analysis…………………………………………….35

4.1 Salmonella enterica strains included in the inoculation cocktail for this study…….……...…………….. 43

4.2 Estimated times required to achieve 1 and 5-log reductions of Salmonella …….………….................. 51

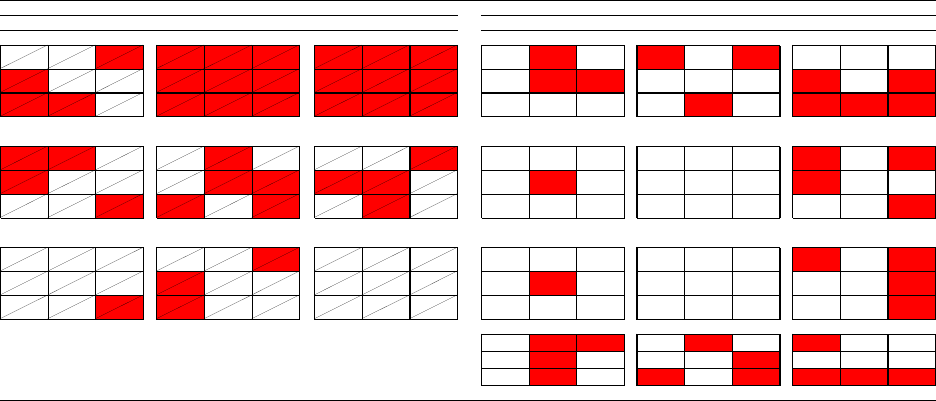

4.3 Qualitative reduction of immersion-inoculated 5 log CFU/ g of Salmonella on hazelnut........................ 54

4.4 Qualitative reduction of spot-inoculated 5 log CFU/ g of Salmonella on hazelnuts………………….. 55

4.5 Ability of consumers to distinguish steam treated hazelnuts from control samples…………………. 57

4.6 Sensory properties of hazelnuts after steam treatment…………………………………….................. 57

1

1. Introduction

Low moisture foods such as tree nuts have traditionally been considered biologically safe due to their low

water activity (a

w

≤ 0.70) (Danyluk et al. 2007). However, outbreaks of enteric pathogens, particularly

Salmonella spp., have been associated with tree nuts, including in-shell hazelnuts in recent years, prompting the

need for new industry risk assessment strategies. The Oregon hazelnut industry is actively searching to better

understand the biological risks associated with hazelnuts and improve the food safety of hazelnuts.

Currently, there are several validated postharvest treatments for the pasteurization of almonds including,

propylene oxide (PPO) fumigation, steam, oil roasting, dry roasting, and hot water blanching that show

promise of application to other tree nut industries. Steam treatment is an effective alternative for in-shell

hazelnuts and other minimally processed tree nuts that cannot be roasted, hot water blanched, or have

chemical residues left behind from PPO fumigation. Evaluation of the efficacy of steam treatment using a

pilot-scale steam blancher will help determine the potential for steam technologies as thermal postharvest

treatments.

In addition, a two-year Salmonella spp. prevalence and quantities survey of in-shell hazelnut samples collected

from Oregon processors will help quantify the risk of Salmonella spp. associated with in-shell hazelnuts. The

results of the prevalence study will help guide future industry risk assessment strategies.

2

2. Literature Review

2.1 Hazelnuts

2.1.1 Hazelnuts

The hazelnut, commonly referred to as filbert, is the fruit of the hazel (Corylus) tree, a genus of deciduous

trees belonging to the birch family Betulaceaeae that consists of approximately 17 species (Holstein et al. 2018).

While one hazelnut species, Corylus cornuta var. californica, is native to the Pacific Northwest, the European

Hazelnut, Corylus avellana, has been cultivated for commercial use and is primarily used for commercial

production world-wide, including the Pacific Northwest (Olsen 2013a). Hazelnuts are a good source of

protein, unsaturated fats (oleic acid), magnesium and vitamins B and E (Richardson 1997). According to

nutritional research, hazelnuts may potentially be beneficial for the heart, help reduce cancer risks, decrease

inflammation, and aid in digestive health (Richardson 1997). The health benefits of hazelnuts have been

purported for centuries. A Chinese manuscript dated 2838 BC lists hazelnuts as one of the five sacred foods

given to man from heaven (Dreher et al. 1996; Olsen 2013a). The Greek philosopher Theophrastus

described the benefits of hazelnuts in his writings, and the Greek physician Dioscorides wrote about using

hazelnuts to treat common ailments such as colds and even baldness (Dreher et al. 1996). Hazelnuts have

been cultivated for over five centuries in China, and evidence of Mesolithic nut processing on Colonsay, an

island in the Inner Herbides of Scotland, where hundreds of thousands of charred hazelnut shells were found

and carbon dated to over 9000 years ago, suggests this island community was trading processed hazelnuts

with other surrounding communities (Mithen et al. 2001). Cultivation of hazelnuts in the Pacific Northwest

and Oregon began in more recent times, and is thought to have first begun in 1858 when Sam Strickland, an

English sailor, planted the first hazelnut tree outside Scottsburg, Oregon using the European cultivar, Corylus

avellana (Olsen 2013a).

2.1.2 Geographic Distribution

Hazelnut trees grow naturally in a variety of conditions and locations. However, hazelnuts thrive at growing

in temperate oceanic climates along the 45

th

parallel, and this latitudinal line intersects both the Willamette

3

Valley in Oregon and Turkey, the world’s largest producer of hazelnuts (Lupo 2019; Olsen 2013a). The

temperate oceanic climates of the Willamette Valley and the Black Sea region of northern Turkey are ideal for

the commercial production of hazelnuts (Olsen 2013a). It is no coincidence that the top three hazelnut

producing countries – Turkey, Italy and the United States – all have moderate oceanic regions in proximity to

the 45

th

parallel that are ideal for the commercial production of hazelnuts. Turkey produces the majority of

hazelnuts world-wide, accounting for approximately 70% of global production, with Italy and the United

States being responsible for approximately 20% and 4% of global production, respectively (Kilic et al. 2006;

Olsen 2013a). Commercial hazelnut production in the United States is unique to the Pacific Northwest.

Specifically, Oregon’s Willamette Valley is responsible for approximately 99% of the United States annual

crop, with Washington producing the remaining 1% (NASS 2019; Olsen 2013a). While the Pacific Northwest

is responsible for about 4% of world hazelnut production, Oregon-grown hazelnuts have gained a global

reputation for their large size and robust flavor.

2.1.3 Growth and Production

Hazelnut trees are monoecious and self-incompatible, meaning they contain both male and female flowers

but cannot self-pollinate (Germain 1994). Hazelnuts pollinate in the winter before ripening in the fall.

Harvest typically begins in late September or October after nuts have ripened, turned hazel colored, and have

fallen to the ground separated from their husks (HMB 2012), and lasts approximately one month.

Mechanical sweepers then align the hazelnuts into uniform rows before a harvesting machine picks up the

hazelnuts, sorts the nuts from other soil and plant debris, and deposits the nuts in trailers or large totes where

they are then transported to processing facilities throughout Oregon (HMB 2012).

Postharvest processing of hazelnuts includes general washing and drying steps to ensure hazelnuts are clean

and of high quality before being distributed to consumers. Washing steps vary commercially, with processors

rinsing or spraying water or diluted food-safe sanitizers on in-shell hazelnuts to remove excess dirt and debris

from the hazelnut shell. After processing, hazelnuts must contain no more than 0.02 percent (w/w) of

4

foreign material (CFR 2008b). After washing, clean hazelnuts are then dried over several days to reduce the

moisture to less than 6 percent (CFR 2008b). Following drying, hazelnuts can be packaged and distributed as

in-shell nuts or undergo additional processing steps such as shelling and roasting. While hazelnuts are

commonly shelled, roasted and incorporated into confectionaries, the majority of Oregon hazelnuts are sold

in-shell and undergo minimal processing.

2.1.4 Oregon Hazelnut Industry

Oregon’s Willamette Valley is the core of the United States hazelnut industry, responsible for producing over

99 percent of the US annual hazelnut crop (Mehlenbacher et al. 1997). Between 2016-2018, Oregon

produced 42,333 tons of hazelnuts on average from 40,333 bearing acres for a total utilized annual

production value of $94.7 million, according to the National Agricultural Statistics Service (NASS 2019).

Historically, the majority of Oregon Hazelnuts (77 percent in 2014) are sold in-shell and undergo minimal

processing.

2.1.5 Oregon Hazelnut Varieties

Major varieties of Oregon hazelnuts have traditionally included Barcelona, Lewis, and Ennis, with Barcelona

historically being the most popular variety (HGO 2019; Olsen 2013b). However, newly developed cultivars

cross-bred for their resistance to the fungal disease, Anisogramma anoamala, compose the majority of new tree

plantings. The popularity of Barcelona trees has been declining since the 1990s, with only about 1 percent of

new plantings using this varietal. A newer hazelnut cultivar – Jefferson – has become the most commonly

planted varietal in Oregon due to its resistance to eastern filbert blight (EFB) caused by the fungus

Anisogramma anoamala, with over 50 percent of new plantings utilizing this EFB-resistant varietal (Olsen

2013b). Eastern filbert blight is a fungal disease that has decimated hazelnut crops over years by causing

severe branch die-back and loss of susceptible trees. The Oregon State University hazelnut breeding program

has been working to develop new hazelnut varieties that in addition to having EFB-resistance, increase annual

production yield, and have desirable kernel characteristics (Olsen 2013b). In addition to Jefferson, other new

5

hazelnut varieties are becoming popular for planting including, McDonald, Wepster, and most recently Polly

O., all of which display resistance to EFB (HGO 2019; Mehlenbacher et al. 2019).

2.2 Outbreaks and Recalls Associated with Tree Nuts

Historically, tree nuts have been considered microbiologically safe due to their low water activity. However,

recent outbreaks of foodborne illness associated with the consumption of tree nuts has led to a reevaluation

of the risks associated with them, with increasing importance placed on preventative control processes. In

addition, detection of foodborne pathogens in prevalence surveys and in recall-associated tree nuts has led to

several class-1 recalls in the United States and Canada in recent years. In 2009, detection of Salmonella in a

single hazelnut processing facility led to the recall of 114,350 lb of shelled hazelnuts (FDA 2009). Additional

recalls of hazelnuts in 2012, 2013, and 2015 were attributed to Salmonella detection in hazelnut samples.

Outbreaks of salmonellosis in the United States and Canada in 2000-2001 and 2003-2004 were

epidemiologically linked to raw almonds (Chan et al. 2002; CDC 2004). An outbreak of E. coli O157:H7

associated with the consumption of in-shell hazelnuts sickened 8 people in the Midwest in 2011 and was the

first case of E. coli O157:H7 being associated with tree nuts (Miller et al. 2012). In 2017, an outbreak of

Salmonella Typhirium which sickened 5 people was traced to an 80-acre Oregon farm and nursery that sold

between 32,000 to 48,000 pounds of raw in-shell hazelnuts directly to consumers from a road-side stand

(Yada et al. 2019). Walnut kernels were additionally implicated in an outbreak of E.coli O157:H7 in 2011.

Due to the increase of illness associated with the consumption of tree nuts, along with increased detection of

foodborne pathogens on tree nuts, a reevaluation of the health risks and efficacy of preventative control

measures is necessary. A summary of recent outbreaks of foodborne illness associated with tree nuts is

shown in Table 1.

6

a

Data obtained from Yada et al. 2019

Table 1

.Outbreaks of foodborne illness associated with the consumption of tree nuts

a

Type

Product

(source)

Pathogen Year

Number

of Cases

Outbreak location(s)

Almond

raw whole

(California)

S. Enteritidis PT

30

2000-01 168 Canada, USA

raw whole

(California)

S. Enteritidis PT 9c 2004 47 Canada, USA

raw whole

(California)

S. Enteritidis NST

3+ (aka PT 30)

2005-6 15 Sweden

raw whole

(Australia)

S. Typhimurium 2012 27 Australia

Coconut

desiccated

(Pap New

Guinea)

S. Typhi, S.

Senftenberg and

possibly others

1953 >50 Australia

desiccated

(Sri Lanka)

S. Paratyphi B 1960-61 3 England

desiccated

(not

stated)

S. Java PT Dundee 1999 18 United Kingdom

dried, raw

S. Newport, S.

Typhimurium

2017-2018 15

USA (CA, CO, CT, MA, NJ,

NY, OK, PA, WA), Canada

Hazelnut

in-shell

(Oregon)

E. coli O157:H7 2010-11 10 Canada, USA (WI, MN, MI)

raw in-

shell

(Oregon)

S. Typhimurium 2017 5 USA (OR)

Pine nut

whole,

bulk

(Turkey)

S. Enteritidis 2011 43 USA (MD, NY, NJ, PA, VA)

Pistachio

roasted

(Calironia)

S. Senftenberg 2013 8

USA (CA, KS, MA, MD, PA,

WI)

roasted

(California)

S. Montevideo, S.

Senftenberg

2015-16 11

USA (AL, AZ, CT, GA, MI,

MN, ND, VA, WA)

Walnut

raw shelled

pieces

(California)

E. coli O157:H7 2011 14 Canada

7

2.2.1 Mandatory Pasteurization of Almonds

In response to the salmonellosis outbreaks linked to almonds, and with pressure from the FDA, the Almond

Board of California (ABC) – a grower-enacted federal marketing association – proposed mandatory

pasteurization of almonds (7 CFR Part 981). Beginning in September 2007, almonds grown in California and

sold in the U.S., Canada, and Mexico must be subjected to a treatment process or processes that achieve a

minimum 4-log reduction of Salmonella. Almond handlers are required to use treatment processes that have

been recognized by a scientific review panel identified by the Almond Board known as the Technical Expert

Review Panel (TERP), or reviewed by the FDA and issued a letter of determination when a process has

sufficiently demonstrated its effectiveness to achieve a 5-log reduction of Salmonella in almonds. While a

minimum 4-log reduction of Salmonella on almonds is considered the mandatory treatment criterion, a 5-log

reduction is required for labeling almonds as “pasteurized”. The TERP currently recognizes several validated

postharvest treatments for almonds, including propylene oxide (PPO) fumigation, steam, oil roasting, dry

roasting, and hot water blanching (ABC 2007d). The steam treatments recognized by the TERP consist of

two proprietary processes – a continuous conveyor system and a batch system – that have been reviewed and

accepted by TERP. Each process has established critical control points for one or two sets of operating

parameters that have been accepted by TERP, and has undergone extensive validation testing using almonds

inoculated with Salmonella Enteritidis PT 30 (SE PT 30). The almond industry is currently the only nut

industry requiring mandatory use of validated postharvest treatments that inactivate Salmonella. Research

conducted on almonds has helped define sanitation standards for tree nuts, and technologies used for

reduction of Salmonella populations on almonds show promise of application to other tree nut industries.

2.2.2 Salmonella Risk Assessment for Tree Nuts

Tree nut industries, along with the FDA, now recognize the increased risk of nut-associated foodborne

illnesses and began taking steps to improve the microbiological safety of tree nuts, with the almond industry

serving as a primary model. Prompted by increasing outbreaks, recalls, and detection of Salmonella in tree

nuts, the U.S. Food and Drug Administration (FDA) began conducting a risk assessment of Salmonella

8

contamination associated with tree nuts in 2013. The purpose of the risk assessment – a planned, multiyear

study – is twofold: to quantify the public health risk associated with eating tree nuts potentially contaminated

with Salmonella, and to evaluate the impact of interventions currently being used or that could be applied in

the future to prevent or reduce Salmonella contamination levels (FDA 2013). The results of the risk

assessment will help inform public policy on nut safety and help guide nut producers on best practices,

according to the FDA.

The Oregon Hazelnut Industry, represented by the Hazelnut Marketing Board, has actively been working to

better understand the risk of Salmonella contamination associated with hazelnuts and to develop validated

processes that inactivate or sufficiently reduce Salmonella and other pathogens on in-shell hazelnuts. Working

with the Hazelnut Marketing Board, the Oregon State University Food Safety Systems laboratory recently

concluded a multi-year (2013-2015) prevalence survey of Salmonella on in-shell hazelnuts. Data collected from

the Salmonella prevalence survey on in-shell hazelnuts will be provided to the FDA for their risk assessment of

Salmonella contamination in tree nuts. In addition to the prevalence study, our lab has been working with the

Hazelnut Marketing Board to investigate the efficacy of postharvest treatments to inactivate or sufficiently

reduce Salmonella on in-shell hazelnuts, including steam treatment, propylene oxide (PPO) fumigation, and

peroxyacetic acid (PAA) washing.

2.2.3 Prevalence of Foodborne Pathogens on Tree Nuts

Much of the available data for the prevalence of foodborne pathogens on tree nuts is derived from retail

surveys using small sample sizes (25g; Davidson et al. 2015; Harris et al. 2019). Prior to 2017, available data

for the prevalence of Salmonella and E.coli on hazelnuts was restricted to several retail surveys form the UK

and Australia that used a limited amount of samples and small sample sizes for determination of prevalence

levels (Harris et al. 2019). Several larger retail surveys of hazelnuts sold in the United States and Canada have

since found the prevalence of Salmonella ranging from 0.0% to 0.43% on in-shell and shelled hazelnuts sold at

the retail level in the United States and Canada (Table 2). Despite these more recent retail surveys, a

9

comprehensive survey of the prevalence of Salmonella occurring at the hazelnut processing level in Oregon

has not been conducted. However, large prevalence surveys have been conducted on California almonds,

pistachios and walnuts, with hundreds to thousands of samples (100-500 g) collected at the processor level

over multiple harvest years (Table 2). In order to make a direct comparison to data derived from the

California tree nut Salmonella prevalence surveys, we devised an in-shell hazelnut Salmonella prevalence study

with a similar design, collecting 472 samples (375 g) from processors over three harvest years (2013-2015).

Available data prior to 2016 from foodborne pathogen surveys of California tree nuts indicate approximately

a one percent contamination level of Salmonella on almonds, pecans, and pistachios, with the exception of in-

shell walnuts, which had a significantly lower incidence of Salmonella contamination (0.14%) (Table 2). A

survey of almonds grown in California found a prevalence of 0.98% (137/13,972) Salmonella on raw almond

kernel samples (100g) over eight harvest years (2001-2007 and 2010) (Bansal et al. 2010; Danyluk et al. 2007;

Lambertini et al. 2012). The average prevalence of Salmonella on raw in-shell almonds grown in California was

1.5% (100 g; 7/455) in 2006 and 2007 (Bansal et al. 2010). The incidence of Salmonella on in-shell walnuts

was found to be 0.14% (100 to 375 g; 4/3,838) over three California harvest years (2011-2014) (Davidson et

al. 2015). The average prevalence of Salmonella contamination on pistachios grown in California was 0.81%

(100g; 32/968) between 2011-2013 (Harris et al. 2016). A recent survey of in-shell pecans collected over four

harvest years (2010-2014) from seven pecan shelling facilities located across five U.S. states, found 44 of

4,641 (0.95%) samples (100 g) positive for Salmonella (Brar et al. 2015). Salmonella population levels in

naturally-contaminated tree nuts are relatively low, ranging from 0.000095 to 39 MPN/100 g upon retesting

(Table 2). The detection of Salmonella in California tree nut surveys, along with increased foodborne

outbreaks being linked to tree nuts, underscores the need for effective postharvest treatments that are

validated to sufficiently reduce (4 to 5 log) Salmonella in tree nuts.

10

Table 2. Prevalence and levels of Salmonella on naturally-contaminated tree nuts in North America

a

A risk assessment model designed by Danyluk et al. (2006) was used to characterize the risk associated with

consumption of raw almonds. The model was based on Monte Carlo simulations and took into account

many of the factors after almonds reached the processors, such as handler and consumer storage times, and

pre-process, post-process, retail, and consumer reduction levels on Salmonella during storage (Pan et al. 2012).

Type of nut Where Collected Sample size (g)

No. o

f

samples

tested (n)

No. positive

for

Salmonell

a

Percent positive

Concentration (Av

g

MPN/100 g)

References

A

lmond, raw kernel

Processor receiving,

California

100 14,949 146 0.98

96 samples: 0.0044 to

0.15 for 2002-06;

4 samples: 0.00080,

0.00080, 0.00095,

0.0034 for 2010

Bansal et al. 2010;

Danyluk et al. 2007;

Lambertini et al. 2012

Almond, raw in-shell

Processor receiving,

California

100 455 7 1.5 18 samples: 1.4 to 18.3 Bansal et al. 2010

A

lmond, in-shell Retail, Canada 25 86 0 0 0 CFIA, 2017

A

lmond, shelled Retail, Canada 25 319 0 0 0 CFIA, 2017

Hazelnut, in-shell Retail, US 375 80 0 0 0 Zhang et al. 2017

Hazelnut, raw shelled Retail, US

375 577 2 0.35

NA

b

Zhang et al. 2017

Hazelnut, in-shell

Retail, Canada 25 696 3 0.43 NA CFIA, 2017

Hazelnut, shelled Retail, Canada 25 870 0 0 0 CFIA, 2017

Macadamia, raw

shelled

Retail, US 375 355 15 4.2 NA Zhang et al. 2017

Pecan, raw in-shell

Processor receiving,

5 U.S. states

100

4,641 44 0.95

44 samples: 0.47 to 39;

mean of 2.4

Brar et al. 2015

Pecan, in-shell Retail, Canada 25 40 0 0 0 CFIA, 2017

Pecan, shelled Retail, Canada 25 86 0 0 0 CFIA, 2017

Pistachio, raw in-shel

l

Processor receiving,

California

100

3,968 32 0.81

11 samples (sinkers):

0.0046

21 samples (floaters):

0.012 to 0.43

Harris et al. 2016

Pistachio, in-shell Retail, Canada 25 481 0 0 0 CFIA, 2017

Pistachio, shelled Retail, Canada 25 22 0 0 0 CFIA, 2017

W

alnut, raw in-shell

Processor,

California

100

935 0 0 0 Davidson et al. 2015

W

alnut, raw in-shell

Processor,

California

375

2,903 4 0.14

3 samples: 0.0032,

0.0038, 0.0042

Davidson et al. 2015

W

alnut, in-shell Retail, Canada 25 792 2 0.25 NA CFIA, 2017

W

alnut, shelled Retail, Canada 25 874 0 0 0 CFIA, 2017

b

Data not determined

a

Data obtained from Harris et al. 2019

11

The model was able to demonstrate that lack of a pasteurization step led to a greater than 78% probability of

more than one case of salmonellosis occurring per year; however, introduction of a pasteurization step

achieving a minimum 4-log reduction reduced the probability of illness to 0.01% according to the model.

Based on this model, the Almond Board’s TERP concluded that a 4-log reduction was a suitable standard for

almond pasteurization, and recommended that a mandatory treatment program be implemented (Pan et al.

2012). A similar risk assessment model developed by Lambertini et al. (2012) ran a simulation with updated

variables such as total amount ingested by consumer, concentration of Salmonella in almonds, assumed storage

times, and temperature distributions throughout all processing steps. The model showed that, under the

current rule mandating a 4-log minimum reduction of Salmonella on almonds, the estimated risk of

salmonellosis was 0.72 cases annually. The model further showed that if a 3-log reduction was mandated

rather than a 4-log reduction, the risk of salmonellosis would be 7.2 cases annually (Pan et al. 2012).

2.3 Validated Postharvest Treatments

Several chemical and thermal treatment technologies have been investigated on almonds for their efficacy at

inactivating Salmonella and other pathogens (i.e. E. coli O157:H7). Chemical treatments have widely been used

on food commodities for their efficacy at controlling or inactivating microbial pathogens while preserving the

original quality of the product. As an alternative to chemical treatments, which may leave residues on the

final product, thermal treatments have long been used on food commodities. However, thermal treatments

exceeding 60°C may negatively affect final product quality if not well controlled (Pan et al. 2012).

Chemical Treatments

2.3.1 Propylene Oxide

Propylene oxide (PPO), a registered fumigant in the US for reduction of bacteria, yeasts, and mold on raw

nut meats, is among the technologies approved by the US Food and Drug Administration (FDA) for the

pasteurization of raw almond kernels (ABC 2008). Research projects funded by the Almond Board of

California (ABC) and carried out by Dr. Linda Harris of the University of California, Davis (UCD), and ABC

12

staff in collaboration with Blue Diamond Growers, Inc. (Sacramento, CA) and Industrial Sterilization (Sparks,

NV) demonstrated that PPO fumigation was effective at achieving a 5-log reduction of Salmonella Enteritidis

PT30 (SE PT30) on inoculated raw almond kernels (Danyluk et al. 2005). The FDA issued a Letter of

Determination confirming the validity of PPO as a pasteurization treatment for raw almond kernels in

September 2004 after reviewing the research findings from the ABC-sponsored studies on the efficacy of

PPO in reducing Salmonella in almonds. Almonds which are fumigated in accordance with the PPO treatment

parameters described by Danyluk et al. (2005) can be labeled as “pasteurized” (ABC 2008). Similar PPO

treatment parameters for in-shell almonds have been conditionally accepted by TERP that achieve a

minimum 4-log reduction of Salmonella. The PPO treatment conditions for hazelnuts must be the same as

those approved for the use in the pasteurization of almond kernels, except that in-shell hazelnuts must be

held for a minimum of 5 days at 15-18

C for post-treatment for ventilation, whereas almond kernels have the

option of be held for 2 days at 38-43

C for post-treatment ventilation.

The US Environmental Protection Agency (EPA) requires that the exposure time to PPO does not exceed 4

h and that the residue on the product is less than 300 ppm (Danyluk et al. 2005). Consequently, the ABC

published a standard operating procedure (SOP) for treatment of almonds kernels and in-shell almonds using

PPO, establishing parameters that are effective at inactivating Salmonella on almonds while following the EPA

requirements of no more than 4 h PPO exposure time and a final product residue less than 300 ppm. A brief

summary of the SOP is as follows: Almonds are pre-warmed to (30

C) before being loaded into a sealed and

pre-heated chamber (47-51

C). The pressure of the chamber is lowered to approximately 9.9 kPa before

PPO is injected into the chamber at a minimum concentration of 0.5 kg/m

3

. Following injection of PPO, an

inert gas (i.e. nitrogen) is pumped into the chamber to maintain a pressure of 84.3 kPa during the 4-h

treatment. A series of aeration cycles (4 to 14 cycles) follow the 4 h process, where a cycle is the decrease of

the chamber pressure to 9.9 kPa followed by an increase to atmospheric pressure with an inert gas or air.

Following the aeration cycle, almonds are transferred to a post-ventilation treatment room for a minimum of

2 days at 38-43

C (almond kernels) or for 5 days above 15

C (almond kernels and in-shell almonds) to

13

achieve a PPO residue of 300 ppm or less on the final product (ABC 2008). Treatment with PPO provides

biologically safe final products while maintaining the integrity and sensory parameters of almonds (Danyluk et

al. 2005). However, public acceptance – particularly in export markets – and the high cost of operation make

PPO treatment impractical for some nut processors. Foreign markets such as the European Union have

strict guidelines on the importation of food commodities treated with PPO and other chemicals, and the

Federal Register estimates the cost of a PPO chamber is between $500,000 and $1,250,000, with alternative

off-site contract processing costing between $0.04 and $0.05 per pound (CFR 2008a).

Thermal Treatments

2.3.2 Oil Roasting

Roasting causes almonds to have a more crunchy texture and alters the flavor profile of nut products (Du et

al. 2010). Oil roasting is used by the almond industry to obtain crunchy and roasted flavors in almond

products (ABC 2007d). Du et al. (2010) demonstrated that immersion of almonds in hot oil (127

C) achieved

a 5-log reduction of SE PT30 in 1.5 min. The authors partly attributed the rapid and large reduction of

Salmonella to washing-off of loosely attached, less protected, and more heat-sensitive pathogen cells (Du et al.

2010). In addition, the efficacy of oil roasting may also result from the high temperature of the oil (127

C)

and the high rate of heat transfer from the oil to the kernel.

Oil roasting parameters (oil temperature and time) are dictated by the desired degree of roast, throughput

rate, initial temperature and initial moisture levels of the almonds, volume of the heated oil, etc. At oil

temperatures of 138

C to 177

C (280

F to 350

F) roasting times of 3 to 15 minutes are typically needed to

achieve crunchy and crispy oil-roasted almond products (ABC 2007d). While oil roasting is able to meet

pasteurization requirements (5-log reduction of SE PT30), it is only applicable to roasted almonds and not to

raw almonds.

14

2.3.3 Dry Roasting

In general, oil roasting is a much faster process than dry roasting using hot air (129

to 154

C). Several

studies initiated by the ABC found that certain existing dry-roasting parameters used by the almond industry

did not deliver a minimum 4-log reduction of SE PT30 on almonds. Yang et al. (2010) demonstrated that dry

roasting almond kernels to a medium level at 130

C was insufficient to achieve a 4-log reduction on SE PT30.

The heat resistance of SE PT30 during dry roasting (hot air) is well documented, with SE PT30 having a D-

value of 25 min at 121.1

C and a Z-value of 26.1

C (ABC 2007c). While dry roasting typically takes much

longer than oil roasting, it has been recognized by TERP as a validated technology to achieve a minimum 4-

log reduction of Salmonella on almonds. Common temperatures for dry roasting range from 129 to 154

C for

10 to 45 minutes. Dry roasting may not achieve the required 4-log reduction of Salmonella on almonds

without significantly impacting the sensory properties of almonds, and is therefore not applicable as a

treatment for raw almonds or other minimally processed tree nuts such as in-shell hazelnuts.

2.3.4 Steam Treatment

Steam at 100

C has a higher heat capacity than the same amount of water at that temperature. One of the

advantages of steam pasteurization is the large transfer of heat when steam condenses on the surface of

foods, which rapidly raises the surface temperature (James et al. 2000). Another attractive feature of

condensed steam team is its ability to penetrate small cavities and condense on cold surfaces that water is

unable to reach. Water vapor molecules are much smaller in diameter (mean free path of steam molecule at

140

C is 0.4 µm) than Salmonella cells (approximately 0.7 µm), making steam capable of reaching bacteria that

occur in cavities (Morgan et al. 1996). Unlike steam, the surface tension of water makes it unable to penetrate

pores of this size. Consequently, water cannot reach all the contaminated surfaces that are large enough to

contain bacterial cells of this size (Morgan et al. 1996).

Several studies have investigated steam pasteurization of Salmonella Enteritidis inoculated on the surface of

almond kernels with mixed results. Using the same almond variety (Nonpareil) and same SE strains (S.

15

Enteritidis 43353, ME-13, ME-14), Chang et al. (2010) were able to demonstrate a 5-log reduction of SE after

exposure to pressurized steam (143 kPa) at 25 s using a batch style, custom made, almond pasteurizer. In

contrast, Lee et al. (2006) were unable to achieve a 4-log reduction of SE even after 35-s exposure to

atmospheric steam using conventional steaming methods. The efficacy of the pressurized steam treatment

observed by Chang et al. (2010) was partly attributed to the rapid increase of temperature within the

pressurized treatment chamber in contrast to the heat dissipation that occurs in open air using conventional

steaming, with the author concluding that the efficacy of steam at inactivating SE is dependent on the

condition of steam applied (Chang et al. 2010). Both authors noted negative impacts on final product quality,

with increasing moisture content and loss in visual quality of almond kernels exposed to steam for prolonged

periods (35 s). A separate study conducted by Bari et al. (2010), demonstrated that a combination of

superheated steam (115

C) for 70 s followed by infrared heating for 70 s was able to achieve a 5-log reduction

of Salmonella on almond kernels without significantly affecting final product quality.

2.3.4.1 Proprietary Steam Technologies

There are currently two proprietary steam technologies that have been reviewed and accepted by TERP.

Both proprietary processes include specific sets of parameters for the treatment of almond kernels and have

undergone extensive validation testing using SE PT30 and established critical control points for one or two

sets of operating parameter that have been accepted by TERP (ABC 2007b).

The two accepted proprietary processes are: the FMC JSP-1 pasteurization system installed at Going Nuts

(Madera, CA) and the H

2

O Express pasteurization system Chamber 1, installed at Stewart & Jasper Company

(Newman, CA) (ABC 2007b). The FMC JSP-1 pasteurization unit is an inline, continuous conveyor system

that treats almonds prior to packaging. Two sets of processing parameters have been accepted by TERP for

the FMC process: one to achieve a 5-log reduction of Salmonella and one to achieve a 4-log reduction. The

FDA, after reviewing the 5-log reduction validation results, issued a Letter of Determination to acknowledge

16

that the FMC JSP-1 pasteurization unit achieves a minimum 5-log reduction of SE PT30 on natural almonds

when operated at defined parameters including belt speed and loading capacity (ABC 2007b).

The H

2

O Express pasteurization system is a batch type system that treats almonds in their final packaging.

For this system, TERP accepted operating parameters for a 4-log reduction of Salmonella on almonds for

three chambers in Newman, CA. The current acceptance only applies to almonds packed in 50-lb cartons for

Chamber 1 and 2,200-lb-tri-wall fiber totes for chambers 1,2, and 3 (ABC 2007b).

Steam treatment is an effective alternative to chemical treatments such as PPO fumigation which may leave

chemical residues.

2.3.5 Hot Water Blanching

Blanching with hot water or steam-injected water is a thermal process used by almond handlers to remove the

pellicle (skin) from almond kernels. Typical hot water blanching processes include scalding and drying steps

where almonds are exposed to heat. Scalding is the step of interest for validation and involves soaking

almond kernels in hot water or steam-injected water (ABC 2007a). Harris et al. (2012) studied the efficacy of

heated water on the reduction of Salmonella on almonds in a hot water bath. In their study, Salmonella could

not be recovered by enrichment after almonds inoculated with SE PT30 and Salmonella Senfentburg 775W at

5-log CFU/g were heated at 88

C for 2 min (Harris et al. 2012). Based on information from this study, the

TERP determined that a minimum process of 2.0 min or more of exposure to hot water at 88

C (199

F) or

above will provide a 5-log or greater reduction of Salmonella on almonds (ABC 2007a). Subsequently, the

FDA reviewed the information and issued a Letter of Determination acknowledging the process was suitable

for pasteurization. Almond products processed utilizing those conditions may be labeled as pasteurized

(ABC 2007a). While approved for pasteurization of almond kernels, hot water blanching may not be a

suitable treatment technology for in-shell hazelnuts and other minimally processed tree nuts due to its effect

on quality and sensory characteristics of the final product – particularly moisture content. In a preliminary

17

trial conducted at the OSU pilot plant, hot water blanching was determined to have negative impacts on the

sensory and quality characteristics of in-shell hazelnuts, with a large increase in moisture content compared to

steam blanching.

2.4 Potential Sources of Microbial Contamination During Tree Nut Production and Processing

Microbial contamination of tree nuts can occur during several stages of nut production and processing.

Salmonella contamination on almonds has mainly been traced to the orchard and huller/sheller facilities.

Contamination in the orchard during harvest was considered the most likely source of Salmonella for

outbreak-associated almonds and Salmonella has been shown to survive and persist in almond huller/sheller

processing facilities (Davidson et al. 2015).

Similarly to almonds, there are several points during the harvest and post-harvest handling of hazelnuts when

Salmonella could easily be introduced. At harvest, hazelnuts fall to the ground before they are mechanically

swept up. Any pathogens introduced to orchard soils could potentially contaminate hazelnuts while they are

exposed to the orchard floor. Studies on almond orchard soils show that Salmonella may persist long-term

and even multiply in contaminated soils (Danyluk et al. 2008). Uesugi et al. (2007) observed that a Salmonella

strain associated with a foodborne outbreak in 2001 was able to persist in an almond orchard for over 5 years.

Microbial contamination of orchard soils is a likely source of contamination for hazelnuts and other tree nuts

that fall to the orchard floor before harvest.

Following harvest, hazelnuts are washed to remove any dirt and plant debris and then dried. Ineffective

washing processes may lead to contamination or cross contamination of hazelnuts because Salmonella is able

to easily cross-contaminate products in a liquid medium. Effective washing procedures are critical for the

biological safety of in-shell hazelnuts and other minimally processed tree nuts.

18

2.5 Pathogens Associated with Tree Nuts

2.5.1 Salmonella spp.

Salmonella is a genus of gram negative, non-spore forming, rod-shaped (bacillus) bacteria of the

Enterobacteriaceae family. Salmonella is divided into two species – Salmonella enterica and Salmonella bongori –

with S. enterica further divided into six subspecies and over 2,500 serovars. Salmonella enterica serovar

Enteritidis and Salmonella enterica serovar Typhimurium are the most common serotypes isolated from

salmonellosis patients in the United States (CDC 2011). Nontyphoidal salmonellosis refers to illnesses caused

by all serotypes of Salmonella except Typhi, Paratyphi A, Paratyphi B, and Paratyphi C. Nontyphoidal

salmonellae are a leading cause of bacterial diarrhea worldwide, causing an estimated 94 million cases of

gastroenteritis and 115,000 deaths globally each year (CDC 2011).

Investigations of Salmonella Enteritidis outbreaks frequently implicate contaminated poultry and egg products

as the source of infection (Patrick et al. 2004). While eggs and poultry products continue to be major vehicles

for the transmission of salmonellae, raw fruits and vegetables have been increasingly implicated in outbreaks

due to modern agricultural practices, such as irrigation with polluted water or fertilization with manure,

sewage sludge, and animal excrement (Beuchat et al. 2013). Outbreaks of Salmonella Enteritidis were linked to

raw almonds in 2000 to 2001 and 2003 to 2004.

2.5.2 E. coli O157:H7

Escherichia coli is a gram-negative, facultatively anaerobic, rod-shaped (bacillus) bacterium of the genus

Esherichia and family Enterobacteriaceae. E. coli are a diverse group of bacteria that naturally inhabit the

gastrointestinal tracts of people and animals. Similarly to Salmonella, over 200 serotypes of E.coli have been

classified serologically. While most E. coli are harmless and an important component of a healthy human

intestinal tract, pathogenic types that can cause diarrhea can be transmitted through contaminated water or

food, or through contact with animal or persons. Pathogenic E. coli strains are categorized into six

pathotypes based upon virulence and host clinical symptom and include: (i) enteropathogenic E. coli (EPEC),

19

which causes diarrhea in children and animals; (ii) enterohemorrhagic E. coli (EHEC), which is responsible for

hemorrhagic colitis and hemolytic-uremic syndrome; (iii) enterotoxigenic E. coli (ETEC), which causes

traveler’s diarrhea and porcine and bovine diarrhea; (iv) enteroaggregative E. coli (EAEC), which causes

persistent diarrhea in humans, and diffusely adherent E. coli (DAEC), a subclass of EAEC which causes

diarrhea in children; (vi) uropathogenic E. coli (UPEC), which causes urinary tract infections in humans and

animals; and (vii) neonatal meningitis E. coli (NMEC), which is responsible for meningitis and sepsis

(Palaniappan et al. 2006).

EHEC, also referred to as Shiga-toxin producing E. coli (STEC), are the most common cause of E. coli

foodborne illnesses, and are estimated to cause more than 265,000 illnesses each year in the United States,

with more than 3,600 hospitalizations and 30 deaths (CDC 2014). Most outbreaks of EHEC infection in the

United States have been caused by EHEC O157:H7 (E. coli O157:H7), which is responsible for more than

75 percent of EHEC infections (Jay et al. 2005).

2.6 Persistence and Survival of Pathogens in Tree Nuts and Other Low-Moisture Foods

Foodborne pathogens are unable to multiply on low moisture foods (water activity <0.70), but are capable of

persisting for long periods on dry surfaces. Studies have shown that Salmonella and E. coli O157:H7 are able

to survive long-term on tree nuts and other low moisture foods, and that pathogenicity may be associated

with survival advantages such at desiccation or thermal resistance (Hiramatsu et al. 2005). In addition, low

water activity has been shown to increase the resistance of Salmonella to thermal (Izurieta et al. 2012) and

chemical treatments (Kieboom et al. 2006). Any treatment process designed for mitigation of pathogens such

as Salmonella on tree nuts will need to address these issues.

20

2.7 References

[ABC] Almond Board of California. 2007a. Guidelines for Validation of Blanching Processes. Almond Board

of California [Online]. Available from: https://www.almonds.com/sites/default/files/blanching-validation-

guidelines.pdf. Accessed: Mar 27, 2020.

[ABC] Almond Board of California. 2007b. Considerations for Proprietary Processes for Almond

Pasteurization and Treatment. Almond Board of California [Online]. Available from:

http://www.almonds.com/sites/default/files/content/attachments/proprietary-processes.pdf Accessed: Mar

27, 2020.

[ABC] Almond Board of California. 2007c. Guidelines for Validation of Dry Roasting Processes. Almond

Board of California [Online]. Available from: https://www.almonds.com/sites/default/files/dry-roast-

validation-guidelines.pdf . Accessed: Mar 27, 2020.

[ABC] Almond Board of California. 2007d. Guidelines for Validation of Oil Roasting Processes. Almond

Board of California [Online]. Available from: https://www.almonds.com/sites/default/files/oil-roast-

validation-guidelines.pdf. Accessed: Mar 28, 2020.

[ABC] Almond Board of California. 2008. Guidelines for Validation of Propylene Oxide Pasteurization.

Almond Board of California [Online]. Available from:https://www.almonds.com/sites/default/files/ppo-

validation-guidelines.pdf. Accessed: Mar 28, 2020.

Bansal, A., Jones, T.M., Abd, S.J., Danyluk, M.D., and Harris, L.J. 2010. Most-probable number

determination of Salmonella levels in naturally contaminated raw almonds using two sample preparation

methods. J. Food Prot. 73:1986–1992.

Bari, M.L., Nei, D., Sotome, I., Nishina, I.Y., Hayakawa, F., Isobe, S., and Kawamoto, S. 2010. Effectiveness

of superheated steam and gas catalytic infrared heat treatments to inactivate Salmonella on raw almonds.

Foodborne Path. Dis. 7:845–850.

Beuchat, L.R., Komitopoulou, E., Beckers, H., Betts, R.P., Bourdichon, F., Fanning, S., Joosten, H.M., and

Ter Kuile, B.H. 2013. Low-water activity foods: increased concern as vehicles of foodborne pathogens. J.

Food Prot. 1:150–172.

Brar, P.K., Strawn, L.K., and Danyluk, M.D. 2015. Prevalence, Level, and Types of Salmonella Isolated from

North American In-shell Pecans over Four Harvest Years. J. Food Prot. 79:352-360.

Canadian Food Inspection Agency (CFIA). 2017. Bacterial pathogens on in-shell nuts and in shelled nuts and

nut butters (2012–2015). Available at: http://www.inspection.gc.ca/food/chemical-

residuesmicrobiology/microbiology/eng/1324284849823/1324285064868.

[CDC] Centers for Disease Control and Prevention. 2004. Outbreak of Salmonella serotype Enteritidis

infections associated with raw almonds-United States and Canada, 2003–2004. MMWR Weekly 53(22):484-

487.

[CDC] Centers for Disease Control and Prevention. 2011. CDC Estimates of Foodborne Illness in the

United States CDC 2011 Estimates: Findings. Centers for Disease Control and Prevention [Online]. Available

from: http://www.cdc.gov/foodborneburden/2011-foodborne-estimates.html. Accessed: Apr 9, 2020.

[CDC] Centers for Disease Control and Prevention. 2014. E. coli general information homepage. [Online].

Available from: http://www.cdc.gov/ecoli/general/index.html. Accessed: Mar 11, 2020.

21

Chan, E. S., Aramini, J.,Ciebin, B., Middleton, D., Ahmed, R., Howes, M., Brophy, I., Mentis, I.,

Jamieson, F., Rodgers, F., Nazarowec-White, M., Pichette, S. C., Farrar J., Gutierrez, M., Weis, W. J.,

Lior, L., Ellis, A .and Isaacs, S. 2002. Natural or raw almonds and an outbreak of a rare phage type of

Salmonella Enteritidis infection. Can. Commun. Dis. Rept. 28(12):97–99. Available at:

http://publications.gc.ca/collections/Collection/H12-21-28-12.pdf. Accessed Apr 10, 2020.

Chang, S.S., Han, A.R., Reves-De-Corcuera, J.I., Powers, J.R., and Kang, D.H. 2010. Evaluation of steam

pasteurization in controlling Salmonella serotype Enteritidis on raw almond surfaces. Lett. Appl. Microbiol.

50:393–398.

[CFR] Code of Federal Regulations. 2008a. Almonds Grown in California. 7 CFR 981. Washington, D.C.:

U.S. Department of Agriculture, Office of the Federal Register.

[CFR] Code of Federal Regulations. 2008b. Hazelnuts Grown in Oregon and Washington. 7 CFR 982.

Washington, D.C.: U.S. Department of Agriculture, Office of the Federal Register.

Danyluk, M.D., Uesugi, A.R., and Harris, L.J. 2005. Survival of Salmonella Enteritidis PT 30 on inoculated

almonds after commercial fumigation with propylene oxide. J. Food Prot. 68:1613–1622.

Danyluk, M.D., Jones, T.M., Abd, S.J., Schlitt-Dittrich, F., Jacobs, M., and Harris, L.J. 2007. Prevalence and

amounts of Salmonella found on raw California almonds. J. Food Prot. 70:820–827.

Danyluk, M.D., Nozawa-Inoue, M., Hristoya, K.R., Scow, K.M., Lampinen, B., and Harris, L.J. 2008. Survival

and growth of Salmonella Enteritidis PT 30 in almond orchard soils. J. Appl. Microbiol. 104:1391–1399.

Davidson, G. R., Frelka, J. C., Yang, M., Jones, T. M., and Harris, L. J. 2015. Prevalence of Escherichia coli

O157:H7 and Salmonella on Inshell California Walnuts. J. Food Prot. 78(8):1547–53.

Dreher, M., Maher, C., and Kearney, P. 1996. The traditional and emerging role of nuts in healthful diets.

Nutrition Reviews. 54(8):241-245.

Du, W.X., Abd, S.J., McCarthy, K.L., and Harris, L.J. 2010. Reduction of Salmonella on inoculated almonds

exposed to hot oil. J. Food Prot. 73:1238–1246.

[FDA] U.S. Food and Drug Administration. 2009. Willamette Shelling Recalls Shelled Hazelnuts Because of

Possible Health Risk. U.S. Food and Drug Administration [Online]. Available from: https://wayback.archive-

it.org/7993/20170404195211/https://www.fda.gov/Safety/Recalls/ArchiveRecalls/2009/ucm194806.htm.

Accessed: Apr, 15, 2020.

[FDA] U.S. Food and Drug Administration. 2013. FDA to assess risk of salmonellosis associated with eating

tee nuts. U.S. Food and Drug Administration [Online]. Available from:

http://www.fda.gov/Food/NewsEvents/ConstituentUpdates/ucm361206.htm. Accessed: Apr 12, 2020.

Germain, E. 1994. The reproduction of hazelnut (Corylus Avellana): A review. Acta Hortic. 351: 195-210.

Available from: https://doi.org/10.17660/ActaHortic.1994.351.19. Accessed: Apr 17, 2020.

Harris, L.J., Lieberman, V., Mashiana, R.P., Atwill, E., Yang, M., Chandler, J.C., Bisha, B., Jones, T. 2016.

Prevalence and amounts of Salmonella found on raw California inshell pistachios. J. Food Prot. 79: 1304-1315

Harris, L.J., Uesugi, A.R., Abd, S.J., and McCarthy, K.L. 2012. Survival of Salmonella Enteritidis PT 30 on

inoculated almond kernels in hot water treatments. Food Res. Int. 45:1093–1098.

22

Harris, L.J., Yada, S., Beuchat, L.R., and Danyluk, M.D. 2019. Prevalence and levels of foodborne pathogens

on naturally contaminated nuts and edible seeds (version 2) [Tables 1–4 and references]. In Surveys for

foodborne pathogens on nuts. Available at: https://ucfoodsafety.ucdavis.edu/low-moisture-foods/nuts-and-

nut-pastes. Accessed: Apr 9, 2020.

[HGO] Hazelnut Growers of Oregon. 2019. Hazelnut Varieties [Online]. Available from:

https://www.hazelnut.com/about-hazelnuts/varieties/. Accessed Apr 11, 2020.

Hiramatsu R, Matsumoto, M., Sakae, K., Miyazaki, Y. 2005. Ability of Shiga Toxin-Producing Escherichia coli

and Salmonella spp. to Survive in a Desiccation Model System and in Dry Foods. Appl. Environ. Microbiol.

71(11):6657-6663.

[HMB] Hazelnut Marketing Board. 2012. Oregon Hazelnuts. Production. Hazelnut Marketing Board.

Available from: http://www.oregonhazelnuts.org/about-us/production/. Accessed: Mar 19, 2020.

Holstein, N., Tamer, S., and Weigend, M. 2018 . The nutty world of hazel names – a critical taxonomic

checklist of the genus Corylus (Betulaceae). European J. of Taxonomy. 409:1-45. Available from:

https://doi.org/10.5852/ejt.2018.409. Accessed Apr 17, 2020.

Izurieta W.P., Komitopoulou, E. 2012. Effect of moisture on Salmonella spp. heat resistance in cocoa and

hazelnut shells. Food Res Int 45:1087-1092.

James, C., Goksoy, E.O., Corry, J.E.L., and James, S.J. 2000. Surface pasteurization of poultry meat using

steam at atmospheric pressure. J Food Process Eng. 45:111-117.

Jay J.M., Loessner, M.J., Golden, D.A. 2005. Foodborne Gasteroenteritis Caused by Escherichia coli. Modern

Food Microbiology. Springer Science. New York, NY. p. 637-655.

Kieboom, J., Kusumaningrum, H.D., Tempelaars, M.H., Hazeleger, W.C., Abee, T., Beumer, R.R. 2006.

Survival, Elongation, and Elevated Tolerance of Salmanella enterica Serovar Enteritidis at Reduced Water

Activity. J Food Prot 69(11):2681-2686.

Kiliç, O. and Alkan, I. 2006. The developments in the world hazelnut production and export, the role of

Turkey. J. of Applied Sciences. 6(7): 1612-1616.

Lambertini, E., Danyluk, M.D., Schaffner, D.W., Winter, C.K., and Harris, L.J. 2011. Risk of

salmonellosis from consumption of almonds in the North American market. Food Res. Int.

45:1166–1174.

Lee, S.Y., Oh, S.W., Chung, H.J., Reyes-de-Corcuera, J.I., Powers, J.R., and Kang, D.H. 2006.

Reduction of Salmonella enterica serovar Enteritidis on the surface of raw shelled almonds

by exposure to steam. J. Food Prot. 69:591–595.Lupo, L. 2019. Hazelnuts: the next almond? Seeding new ways

from the old, HGO seeks to grow hazelnut consumption to new heights. Quality Assurance and Food Safety

Magazine. Available at: https://www.qualityassurancemag.com/article/hazelnuts-the-next-almond/.

Accessed Apr 9, 2020.

Mehlenbacher, S.A. and Olsen, J. 1997. The Hazelnut Industry in Oregon, USA. Acta Hortic 445:337–345.

Mehlenbacher, S.A., Smith, D.C. , and McCluskey, R.L. 2019. ‘Polly O’ Hazelnut. HortScience 54(8):1429-1432.

23

Miller, B.D., Rigdon, C.E., Ball, J., Rounds, J.M., Klos, R.F., Brennan, B.M., Arends, K.D., Kennelly, P.,

Hedberg, C., and Smith, K.E. 2012. Use of traceback methods to confirm the source of a multistate

Escherichia coli O157:H7 outbreak due to in-shell hazelnuts. J. Food Prot. 75:320–327.

Mithen, S., Finaly, N., Carruthers, W., Carter, S., and Ashmore, P. 2001. Plant use in the Mesolithic: evidence

from Staosnaig, Isle of Colonsay, Scotland. J Archaeol Sci 28(3): 223–234.

Morgan, A. I., Goldber, N., Radewonuk, E.R., and Scullen, O.J. 1996. Surface pasteurization of raw poultry

meat by steam. LWT-Food Science and Technology. 29: 447-451.

[NASS] National Agricultural Statistics Service. 2019. NW Noncitrus Fruits and Nuts 2018 Summary. USDA

National Agricultural Statistics Service. [Online]. Available from:

https://www.nass.usda.gov/Publications/Todays_Reports/reports/ncit0619.pdf . Accessed Apr 9, 2020.

Olsen, J. 2013a. Growing Hazelnuts in the Pacific Northwest. Oregon State University Extension

publication. [Online]. Available from:

http://ir.library.oregonstate.edu/xmlui/bitstream/handle/1957/43804/em9072.pdf. Accessed: Mar 3, 2020.

Olsen, J. 2013b. Growing Hazelnuts in the Pacific Northwest. Oregon State University Extension

publication. [Online]. Available from:

http://ir.library.oregonstate.edu/xmlui/bitstream/handle/1957/43808/em9073.pdf. Accessed: Mar 3, 2020.

Palaniappan, R., Zhang, Y., Chiu, D., Torres, A., DebRoy, C., Whittam, T.S., and Chang, Y. 2006.

Differentiation of Eschericia coli Pathotypes by Oligonucleotide Spotted Array. J. Clinical Microbiology.

44(4):1495-1501.

Pan, Z., Bingol, G., Brandl, M.T., and McHugh, T.H. 2012. Review of current technologies for

reduction of Salmonella populations on almonds. Food Bioprocess Technol. 5:2046–2057.

Patrick, M.E., Adcock, P.M., Gomez, T.M., Altekruse, S.F., Holland, B.H., Tauxe, R.V., and Swerdlow, D.L.

2004. Salmonella Enteritidis infections, United States, 1985-999. Emerg Infect Dis. 10: 1-7.

Richardson, D.G. 1997. The health benefits of eating hazelnuts: implications for blood lipid profiles,

coronary heart disease, and cancer risks. Acta Hortic. 445:295-300. Available from:

https://doi.org/10.17660/ActaHortic.1997.445.39. Accessed: Apr 16, 2020.

Uesugi, A.R., Danyluk, M.D., Mandrell, R.E., and Harris, L.J. 2007. Isolation of Salmonella Enteritidis phage

type 30 from a single almond orchard over a 5-year period. J. Food Prot. 70:1784–1789.

Yada, S., and Harris, L.J. 2019. Recalls of tree nuts and peanuts in the U.S., 2001 to present (version 2) [Table

and references]. In U.S. recalls of nuts. Available at: http://ucfoodsafety.ucdavis.edu/Nuts_and_Nut_Pastes.

Accessed: Apr 9, 2020.Yang, J., Bingol, G., Pan, Z., Brandl, M.T., McHugh, T.H., and Wang, H. 2010.

Infrared heating for dry-roasting and pasteurization of almonds. J. Food Eng. 101:273–280.

Zhang, G., Hu, L., Melka, D., Wang, H., Laasri, A., Brown, E. W., Strain, E., Allard, M., Bunning, V. K.,

Musser, S. M., Johnson, R., Santillana Farakos, S. M., Scott, V. N., Pouillot, R.,Van Doren, J. M., and

Hammack, T. S. 2017. Prevalence of Salmonella in cashews, hazelnuts, macadamia nuts, pecans, pine nuts,

and walnuts in the United States. J. Food Prot. 80:459–466. Available at:

http://www.jfoodprotection.org/doi/pdf/10.4315/0362-028X.JFP-16-396.

24

3. PREVALENCE AND LEVELS OF

SALMONELLA

SPP. ON IN-SHELL OREGON

HAZELNUTS OVER THE 2013 AND 2014 HARVESTS

Authors

Christopher A. Letchworth, Joy Waite-Cusic, Robert J. McGorrin*

Department of Food Science and Technology, Oregon State University, Corvallis, Oregon

97331, U.S.A.

*Corresponding author: Robert J. McGorrin, robert.mcgorrin@oregonstate.edu

Research Note

25

3.1 Abstract

A multi-year Salmonella spp. prevalence study was conducted to support risk assessment strategies for

Oregon’s hazelnut industry. During the 2013 and 2014 harvest seasons, raw, green-dried in-shell hazelnut

samples (n = 472) were collected by six of the largest industry handlers and tested for the presence of

Salmonella spp. using a modified method from the Food and Drug Administration’s (FDA) Bacteriological

Analytical Manual (BAM). Samples of in-shell hazelnuts (375 g) were enriched in 1:10 lactose broth followed

by selective enrichment in Rappaport-Vassiliadis Broth (RV) and Tetrathionate Broth (TT). Selective

enrichments were isolated onto Hektoen Enteric (HE) and Xylose Lysine Desoxycholate (XLD) Agars.

Colonies displaying typical morphology for Salmonella spp. were confirmed on CHROMagar Salmonella Plus.

When a sample was positive for Salmonella, the pathogen level was determined by a most-probable-number

(MPN) method (3 x 333, 33.3, 3.3 g) following the same cultural steps as the initial testing. Salmonella spp.

prevalence on in-shell hazelnuts by year was 21.7% (55/254) and 46.8% (102/218) for 2013 and 2014,

respectively. Contamination levels averaged 2.6 MPN/100 g with a range of 0.092 to 30.7 MPN/100 g.

Salmonella prevalence on in-shell hazelnuts is drastically higher compared to prevalence studies for other tree

nuts. Further investigation is needed to understand the contributing factors leading to these high rates of

contamination as well as mitigation factors to improve the food safety of hazelnuts.

26

3.2 Introduction

Outbreaks of foodborne illness associated with the consumption of tree nuts have increasingly been

documented in recent years, including in-shell hazelnuts. Raw almonds were implicated in outbreaks of

salmonellosis in the United States and Canada in 2000-2001 (Isaacs et al. 2005) and 2003-2004 (CDC 2004),

prompting the California almond industry to voluntarily adopt mandatory pasteurization of raw almonds

beginning in 2007. In 2011, outbreaks of E. coli O157:H7 were epidemiologically linked to in-shell hazelnuts

and walnut kernels (CDC 2011; Davidson et al., 2015). A 2017 outbreak of Salmonella Typhirium sickened 5

people and was traced to an 80-acre Oregon farm and nursery that sold between 32,000 to 48,000 pounds of

raw in-shell hazelnuts directly to consumers from a road-side stand (Yada et al. 2019). In 2013, prompted by

outbreaks and recalls of Salmonella contamination in tree nuts, the U.S. Food and Drug Administration (FDA)

began conducting a multiyear, planned risk assessment of Salmonella contamination associated with tree nuts.

The risk assessment is intended to quantify the public health risk associated with eating tree nuts potentially

contaminated with Salmonella and to evaluate the impact of interventions to prevent Salmonella contamination

or reduce its contamination levels (FDA 2013). Foodborne pathogen surveys from tree nuts that quantify the

prevalence and amounts of pathogens, such as Salmonella, provide valuable data when making quantitative risk

assessments.

Oregon’s Willamette Valley produces approximately 99 percent of the United States annual hazelnut crop.

According to the National Agricultural Statistics Service (NASS), between 2016-2018, Oregon produced

42,333 tons of hazelnuts on average from 40,333 bearing acres for a total utilized production value of

$94.7million (NASS 2019). Historically, the majority of Oregon hazelnuts (77 percent of total yield in 2014)

have been sold in-shell and undergone minimal processing (NASS 2015). However, recent trade tariffs with

China have disrupted the supply chain of in-shell hazelnuts that are typically exported to China, and more

hazelnuts are being sold shelled. For example, between 2016-2018, almost half (47 percent) of the total yield

of Oregon Hazelnuts were sold shelled, compared to only 23 percent in 2014 (NASS 2019).

27

Salmonella is unable to multiply on the surface of tree nuts due to the low water activity (generally less than

0.70), but is able to persist on tree nuts for prolonged periods and has been shown to survive in production

and processing environments. There are several points during the harvest and post-harvest handling of

hazelnuts when Salmonella could feasibly be introduced. Before harvest, hazelnuts ripen and fall to the

orchard floor before they are mechanically swept up. Hazelnuts may be exposed to pathogens in soil, water,

and manure on the orchard floor. After harvest, hazelnuts are washed to move any dirt and debris and then

dried. Inadequate washing procedures may lead to contamination or cross-contamination as Salmonella is able

to easily contaminate products in a liquid medium. Cross-contamination of hazelnuts may occur during

processing, handling and storage (GMA 2016). Salmonella populations were found to be stable on inoculated

almonds after over a year in cold storage (4°C) (Kimber et al. 2012; Uesugi et al. 2006). In addition, Salmonella

strains associated with foodborne outbreaks have been shown to survive in contaminated almond orchard

soils for over 5 years (Uesugi et al. 2007). Persistence of Salmonella has led to recalls of tree nuts, including

hazelnuts grown in Oregon. Between 2009 to 2015, there were 4 class-1 recalls of hazelnuts in the United

States and Canada due to Salmonella contamination (Yada et al. 2019).

Large-scale prevalence surveys of California almonds, walnuts, pecans, and pistachios have been conducted

over multiple harvest years with hundreds to thousands of samples (100-500 g) collected at the processor

level (Harris et al. 2019). Available data for the prevalence of Salmonella on hazelnuts is limited to several

retail surveys in the UK and Australia that used a limited amount of samples and small sample size (25g)

(Davidson et al. 2015; Harris et al. 2019). This study was undertaken to characterize the likelihood of

Salmonella contamination among in-shell hazelnuts produced in Oregon over several years. The primary study

objective was to determine the prevalence and levels of Salmonella in minimally processed in-shell hazelnuts

collected from processors throughout Oregon’s Willamette Valley.

28

3.3 Materials and Methods

3.3.1 Hazelnut Sample Collection

In-shell hazelnuts from the 2013 and 2014 harvests were collected from six large hazelnut handlers located in

the Willamette Valley in Oregon. Hazelnut samples were collected three times a week during active season

(middle September – late October) following the first drying stage (green dry). Personnel from the Hazelnut

Marketing Board collected samples from the handlers and delivered samples to Oregon State University each

afternoon to ensure the identity of the processors and origin of samples remained anonymous to lab

personnel. In 2013, no information was collected about any of the samples. In 2014, random numerical

codes were used to unmask sample results to handlers after all nuts were out of commerce.

Each handler was asked to provide samples from four separate lots of hazelnuts per collection day. Each

sample consisted of four subsamples (>100g/subsample) collected from various locations throughout the lot.

Subsamples were collected in sterile Whirl-Pak bags (Nasco, Salida, CA) and placed inside a larger zipper-style