Engineers Newsletter

providing insights for today’s hvac system designer

© 2011 Trane, a business of Ingersoll Rand. All rights reserved. 1

volume 40 –2

HVAC Refrigerants: A Balanced Approach

Refrigerant History

In the early years, the primary focus

of the HVAC industry was simply on

finding a refrigerant that would

provide effective cooling. Many of

the early refrigerants such as sulfur

dioxide, methyl chloride and

ammonia met that objective but

posed safety hazards due to their

toxicity or high flammability

potential.

In the 1930s, chlorofluorocarbon

(CFC) refrigerants were introduced

as safe alternatives to the chemicals

used before them. CFCs came to

dominate first refrigeration and later

HVAC because of their safety and

efficiency. Hydrochlorofluorocarbons

(HCFCs) were added to the portfolio

of refrigerant alternatives in the

1950s.

In the 1970s, environmental

concerns came into play. Scientists

discovered that CFCs—and to a

lesser extent HCFCs—were

contributing to the depletion of the

ozone layer.

Montreal Protocol. Global concern

about depletion of the ozone layer

resulted in the Montreal Protocol, an

international treaty that established

phase-out dates for the use and

production of ozone-depleting

substances. It went into effect in

1987, first targeting CFCs, then HCFCs.

CFCs were replaced with HCFCs,

which have lower ozone-depletion

potential (ODP), or with

hydrofluorocarbons (HFCs), which have

zero ODP. The CFC phaseout was

completed in 1996.

Due to their low ODP, the phase-out

dates for HCFCs were set out later—

from 2004 to 2030 (2040 in developing

countries).

Kyoto Protocol. In the 1990s,

concerns grew that the refrigerants

being phased in because of their

favorable ODP were contributing to

global warming. The global-warming

potential (GWP) of refrigerants now

became a factor.

These concerns with global climate

change led to the Kyoto Protocol,

created in 1997. Kyoto set reduction

targets for greenhouse gases, including

HFCs, in developed countries. Because

CFCs and HCFCs were already covered

under the Montreal Protocol, they were

not included in the Kyoto Protocol.

Where we are today. Both protocols

allow each participating country to

control its own reductions of the

refrigerants to meet their compliance

obligations. In the United States, the

U.S. Environmental Protection Agency

(EPA) issued regulations under the

Clean Air Act to phase out the

One of the constant themes

throughout the history of the HVAC

industry is the search for a better

refrigerant. When considering

alternative refrigerants,

manufacturers need to balance

efficiency with environmental

impact to determine the optimal

replacement.

This EN will provide a brief history

of refrigerants used in the HVAC

industry and the developing

regulations. From there, we’ll

discuss considerations for new and

existing equipment, along with

refrigerant replacement options

and risks.

2 Trane Engineers Newsletter volume 40–2 providing insights for today’s HVAC system designer

production and import of CFCs and

HCFCs.

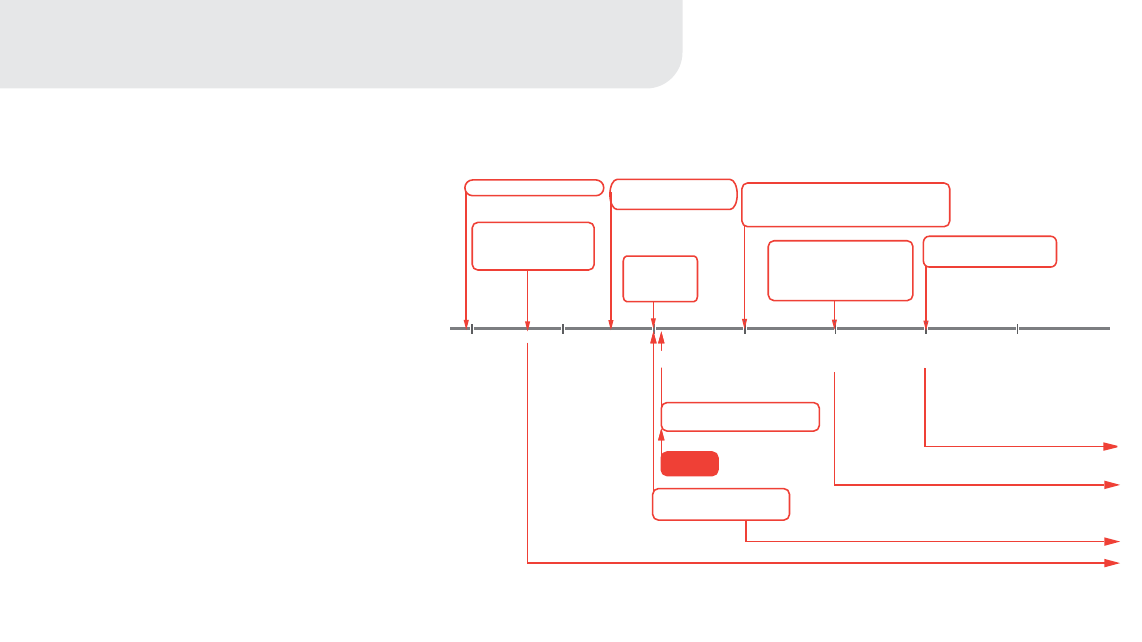

Figure 1 provides a summary of the

major actions involving refrigerants in

developed and developing countries.

The dates on the chart are for the

United States and Canada (dates in

other countries vary).

The Montreal and Kyoto protocols have

set dates to ensure long-term

availability. When production of a

refrigerant stops, the time lines allow

for the recycled, recovered and

stockpiled supplies to continue to be

used without restriction. For example,

production of CFCs ended in 1996, but

inventory of these refrigerants is still

readily available.

What’s ahead. Policy pressure

impacting nearly all commercially viable

refrigerants available today has

accelerated the development of

alternatives.The next family of

refrigerants, known as

hydrofluoroolefins (HFOs), have

properties similar to HCFCs and HFCs

but with minimal direct environmental

impact. The first HFO on the market

has been developed to replace R-134a

for automotive applications and will

begin implementation this year in

Europe. Implementation of HFOs will

lag in the HVAC industry as

manufacturers develop and test new

alternatives, and global regulators

decide on a future path.

A Balanced Approach

When considering refrigerant

alternatives for the future, policy

makers, the public, and manufacturers

must balance direct environmental

concerns (ODP, GWP, leak rates),

indirect environmental concerns

(energy efficiency), safety and

performance.

Direct versus indirect impact. The

direct environmental impact of an HVAC

system is dependent on the ODP and

GWP of the refrigerant and the rate of

refrigerant leakage into the

environment.

While leakage rates can vary widely

among different HVAC products, good

design and servicing can keep leakage

to a minimum. (See the sidebar on p. 4.)

Years ago, when chillers used CFCs and

service practices were less concerned

with minimizing emissions, leak rates

were 2½ to 10 times what they are

today. Due to advances in technology

and the use of refrigerants with

significantly lower GWP, the direct

environmental impact from HVAC

equipment is now from 20 to 600 times

lower than the older CFC chiller designs.

These reduced leak rates, coupled with

newer refrigerants, bring the direct

global warming impact to under 5

percent of the application’s total global

warming impact.

For hermetic systems, up to 95 percent

of the total environmental impact is the

indirect impact—the energy used to

power HVAC systems. According to the

U.S. Department of Energy, 83 percent

of the primary power consumed in the

U.S. is generated by the burning of fossil

fuels, which emits greenhouse gases.

When considering both the direct and

indirect environmental impact, HCFCs

and HFCs, because of their high energy

efficiency, can be the most

environmentally responsible and

appropriate refrigerants available today

for many HVAC applications.

Evaluating alternatives. Let’s take a

look at the refrigerants that are currently

available, taking into consideration their

efficiency, direct and indirect

environmental impact, and safety.

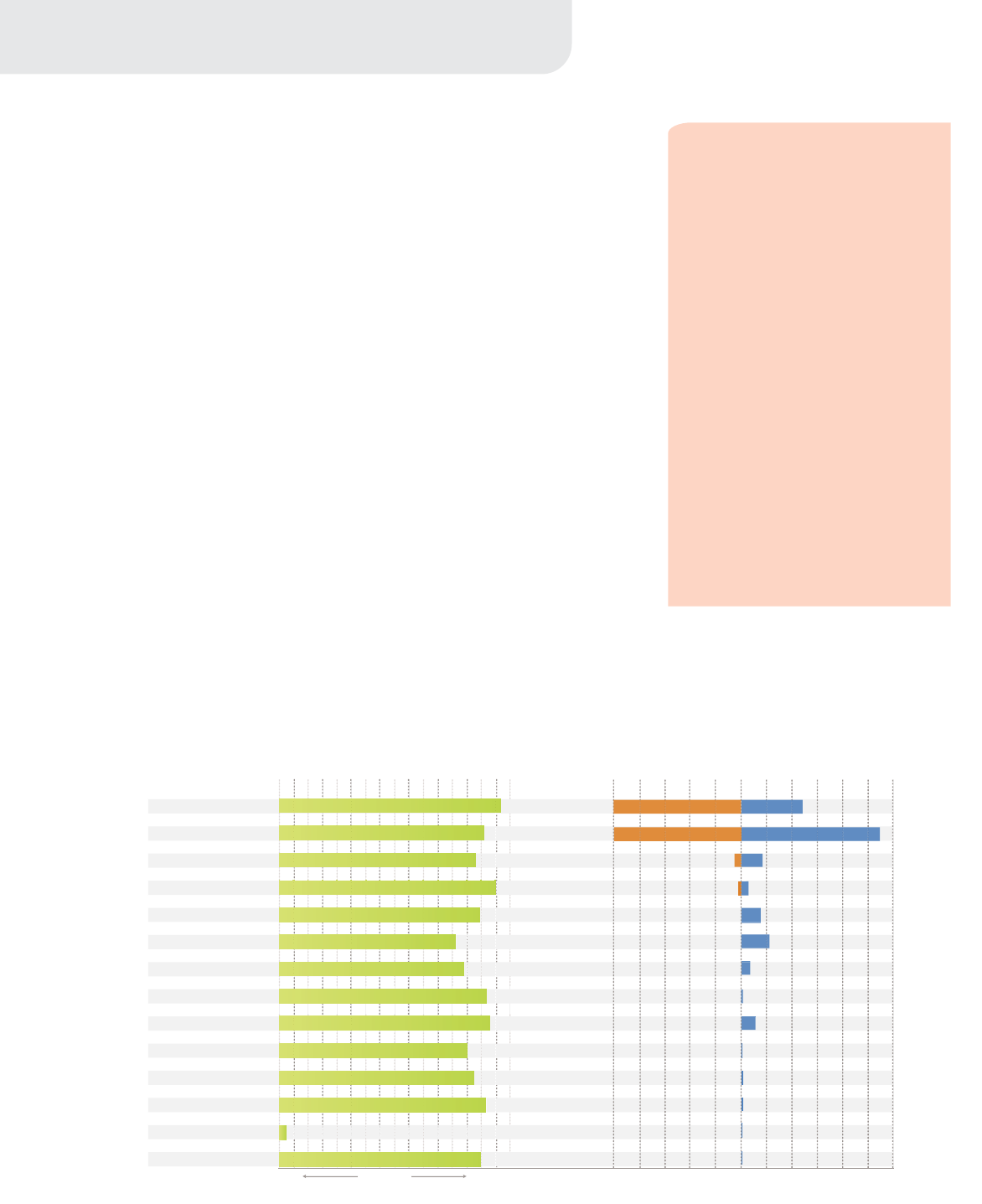

Figure 2 compares the ODP, GWP and

energy efficiency of today’s commercial

refrigerants and potential future

refrigerants. While there is no perfect

refrigerant, the chart shows that

HCFC-123 (R-123), HFC-152a (R-152a)

and HFC-32 (R-32) strike a good balance

between ODP, GWP and efficiency.

However, the use of R-152a and R-32 is

limited because of flammability.

Refrigerants such as CO

2

, hydrocarbons

and ammonia have zero ODP and a very

low GWP. Let’s take a closer look.

Figure 1. Legislative actions involving refrigerant

1990 2000 2010 2050204020302020

Montreal Protocol signed

All CFC production

stopped (R -11,R-12) in

developed countries

No new R-22 for service in US, Canada

No new equipment with R-123 in

developed countries

No new R-123 for service

in developed countries, no

HCFCs in new equipm ent

in developing countries

No HCFC production in

developing countries

Kyoto Protocol went

into effect

No R-134a use in new model

automobiles in Europe

No CFCs for

developing

countries

No new equipment

with R-22 in US, Canada

Today

continued use of recycled CFCs

continued use of recycled R-22

continued use of recycled R-22,

R-123 for developing countries

continued use of recycled R-123

Note: Included in the use of “recycled” refrigerants is also the use of stockpiled supplies of the refrigerant produced

before the phase-out date. In addition, there is no restriction on the importation of recycled and recovered supplies of

refrigerant.

3 Trane Engineers Newsletter volume 40–2 providing insights for today’s HVAC system designer

Carbon dioxide. CO

2

has potential as

a low-temperature refrigerant in

refrigeration applications. However, it

has very low efficiency in HVAC

applications, more than 20 percent

below the efficiency of R-22 and

R-410A, due to operation above the

critical point of CO

2

in these

applications. Today’s equipment would

therefore consume at least 20 percent

more energy with CO

2

to get the same

cooling tonnage, compared to the

existing HCFCs and HFCs used today.

Switching from fluorocarbons to CO

2

to reduce direct environmental impact

(5 percent), while significantly

increasing the indirect impact (95

percent), would not be a good trade-

off.

Hydrocarbons. Hydrocarbons may

perform well in stationary air

conditioning applications, but they

present safety issues in application,

service and recovery because they are

highly flammable.

Ammonia. Ammonia has been used

for years and has potential for low-

temperature and process chiller

applications in remote locations or

where people density is low. Its

flammability and high toxicity strictly

limit its broader use.

Maintaining a balance between the

lowest possible refrigerant emissions

and the best possible energy efficiency

is the key to being both

environmentally and economically

responsible. Achieving this balance in a

cost effective manner is critical in order

to make these new designs affordable

for the end user.

Figure 2. Overview of the environmental impact of current refrigerants

GWP

(CO

2

=1.0)

ODP

(R-11=1.0)

0 24681012

(000s)

1.0 0.8 0.6 0.4 0.2

CFC-11

CFC-12

HCFC-22

HCFC-123

HFC-134a

HFC-410A

HFC-32

HFC-245fa

HFO-1234yf

R-290 (propane)

R-600a (isobutane)

R-744 (CO

2

)

R-717 (ammonia)

higher

Energy efficiency

COP (at typical chiller conditions)

some flammability

some flammability

flammability

flammability

flammability & toxicity

efficiencylower

3.0

3.5 4.0

5.5

4.5

5.0

6.0 6.5

HFC-152a

some flammability

Green building and refrigerant

selection

Green building rating systems such as

USGBC’s LEED (Leadership in Energy

and Environmental Design) and GBI’s

Green Globes take refrigerant usage into

consideration. The current LEED rating

system uses a formula to calculate the

impact of ozone depletion, global

warming, equipment life, leakage rate,

and refrigerant charge. The Green

Globes rating system accounts for ozone

depletion, global warming and leak

detection.

By following the criteria in the rating

systems, the selected refrigerants can

help the project achieve points toward

green building status. For example, most

centrifugal chillers (both R-123 and

R-134a) can achieve the refrigerant

points for LEED Energy and Atmosphere

credit 4. Many split systems, due to the

large volume of refrigerant, cannot.

For more information, see

www.usgbc.org or www.thegbi.org.

4 Trane Engineers Newsletter volume 40–2 providing insights for today’s HVAC system designer

Options for Existing

Equipment

So, what do we do with existing

equipment containing refrigerants that

will be phased out?

There is no definitive answer. However,

there are options and a logical

progression to determine the best

solution for each project.

Options:

• Maintain existing refrigerant

• Replace the refrigerant

• Replace the equipment

Evaluate existing equipment

The first step is to evaluate the current

inventory of equipment. When tracking

the current inventory, obtain records

that document the energy performance

and refrigerant leakage rate of existing

equipment.

Track leakage rate of equipment. The

U.S. Clean Air Act requires that leakage

rate data records be kept for all

equipment with more than 50 lbs of

refrigerant charge. These records

should be available either from the

owner's maintenance records or from

the records of the servicing contractor.

If records are unavailable, then record

keeping should begin immediately to

understand the state of the existing

equipment.

As of January 2011, for equipment with

more than 50 lbs of refrigerant charge,

the U.S. EPA’s maximum allowable

leakage rates over a 12-month period

are:

• Commercial refrigeration:

35 percent

• Industrial process refrigeration:

35 percent

• Comfort cooling:

15 percent

Venting is prohibited for any equipment,

regardless of size.

A note regarding equipment using

HFCs: There are no specific record-

keeping requirements or maximum

leakage rates for this equipment, but

due to direct global warming, venting of

these chemicals is also prohibited. In

the future, maximum leakage rates will

most likely cover the HFCs as well.

Track the equipment performance.

The performance data of the equipment

can be provided either by the building

automation system (preferred), or by

the original nameplate data of the

equipment. Proper service practice

should be able to maintain close to

original performance on most

equipment, but individual equipment

monitoring will provide an even better

performance baseline.

Evaluate refrigerant changeout

Before replacing a refrigerant,

determine the capacity and efficiency

impact. This impact is clearly

understood in some equipment types,

such as centrifugal chillers, where

replacements are clearly defined and

several years of performance data has

been accrued.

For other equipment, there are many

replacement options in the marketplace,

and even more claims of seemingly

miraculous capacity and efficiency

improvements by using these

replacements. Basic physical properties,

as well as industry experience, have

clearly shown that any refrigerant

replacement in existing equipment will

result in some sort of capacity and

efficiency reduction. The specific

reduction depends on the type of

equipment and the specific

replacement refrigerant. Note: When

retrofitting existing equipment, do not

use a flammable refrigerant in

equipment that was not specifically

designed for it.

Replacements for the refrigerants R-11

and R-12 are relatively straightforward

(R-123 and R-134a, respectively). The

decision gets more complex with the

replacement of R-22. Many solutions

are available, and it is impractical for

equipment manufacturers to test and

analyze all of them. Generally, these

replacements incorporate the use of

multi-chemical blends in order to mirror

the properties of R-22. Note: Because

of its higher operating pressure,

R-410A cannot be used in R-22

products.

Blends work in many applications, but

be sure to weigh the following risks:

• Different leakage rates

Concerns exist in the marketplace

about what happens when

refrigerant leaks occur. The

different components in the blend

could potentially leak at different

rates, and therefore change the

composition and performance of

the equipment. When these

replacement refrigerants

incorporate as many as four or

more chemicals in the blend, these

concerns increase.

Use best practices to minimize

environmental impact

Best practices in design and servicing can

keep refrigerant leaks to minimal levels. In

fact, a Trane study conducted as far back as

1997 determined the annualized total loss

rate for every single R-123 chiller that Trane

had under service contract at the time. The

study included all leaks whether from

accidental discharge, servicing or normal

operation. It showed that of 2768 R-123

chillers studied, only 16,229 pounds per

year of charge was lost—less than 0.4575

percent annual leakage rate.

It's important to note that operating

pressure can also impact how likely a leak

is to occur and how much refrigerant will

escape during a leak. In addition,

innovative technologies can be employed

that minimize the refrigerant charge for a

given amount of refrigeration or cooling

capacity, with the percent charge reduction

directly reducing refrigerant emissions over

the life of the equipment by the same

amount. So, use of low pressure technology

with reduced refrigerant charge levels can

result in nearly an order of magnitude

reduction in lifetime emissions compared to

other higher pressure centrifugal chillers.

5 Trane Engineers Newsletter volume 40–2 providing insights for today’s HVAC system designer

• Change in oil

In many cases, a refrigerant

changeout requires a change in the

oil needed in the system. CFCs and

HCFCs are able to use mineral oil

with the refrigerant. HFCs,

however, generally require the use

of POE or other synthetic oils.

So that an oil change may not be

required, many of the R-22

substitutes incorporate a small

amount of hydrocarbons, such as

butane, in order to improve their

miscibility with mineral oil.

However, the refrigerant and oil

chosen must have sufficient

solubility and miscibility throughout

the refrigeration system—which

may not be the case for some R-22

substitutes and mineral oil. If in

doubt, consult the unit or

compressor manufacturer for the

required oil type.

When a refrigerant and/or oil

changeout is evaluated, all the

components of the refrigeration

system must be scrutinized for

compatibility with the refrigerant

and oil. Gaskets and o-rings are of

particular importance because they

may shrink or expand and cause a

refrigerant release. It is strongly

suggested that the gaskets and

o-rings be proactively replaced

during a refrigerant or oil

conversion.

• Future availability and GWP

If a proprietary blend is used for an

alternative refrigerant, it should be

ensured that the blend will still be

available in the future. In addition,

many of these blends are very high

in GWP. The GWP of refrigerants

will likely be regulated or taxed in

the coming years, making many of

the alternatives unattractive.

Review and assess

After you have reviewed the data and

evaluated the possibility of refrigerant

changeout, determine the best solution

for your particular application.

In most cases, retaining the existing

refrigerant in the equipment, or

replacing the equipment altogether will

make the most sense. If leakage rates

with the existing refrigerant cannot be

contained to a minimal level with the

current refrigerant, then it is unlikely

that leaks will be contained with the

new refrigerant. In addition, significant

investments in inefficient equipment

that will result in a loss in capacity and

efficiency will often not be the most

attractive solution. In many cases,

investment in minimizing leaks and

maintaining the equipment to its peak

energy performance will result in a

smaller up-front investment and better

life cycle cost.

Summary

Since the early 1900s, the HVAC

industry has been faced with the

challenge of constantly changing

refrigerants. While change is constant,

it’s important to remember that the

industry has successfully navigated

refrigerant phaseouts in the past and

can apply the lessons learned to future

transitions. As an industry, the key is to

carefully consider alternatives and

strike a balance that is financially and

environmentally responsible.

Today we have good, solid refrigerant

options and availability with HCFCs and

HFCs. There’s no need to panic. The

future will bring different options,

challenges, and opportunities.

By Jeff Moe, director, global policy and advocacy

for the Center for Energy Efficiency and

Sustainability, Ingersoll Rand; Mike Thompson,

global leader of refrigerant strategy, Trane; and

Beth Bakkum, information designer, Trane. You

can find this and previous issues of the Engineers

Newsletter at www.trane.com/EN. To comment,

e-mail us at comfor[email protected].

6 Trane Engineers Newsletter volume 40–2 ADM-APN041-EN (June 2011)

Trane believes the facts and suggestions presented here to be accurate. However, final design and

application decisions are your responsibility. Trane disclaims any responsibility for actions taken on

the material presented.

Trane,

A business of Ingersoll Rand

For more information, contact your local Trane

office or e-mail us at [email protected]

Engineers

Newsletter

LIVE!

To register, contact your

local Trane office.

Upgrading Existing

Chilled-Water

Systems

Now available on-demand

at www.trane.com/ContinuingEducation

June 2011

High-Performance

VAV Systems

October 2011

Dedicated

Outdoor Air Units

New On-Demand Courses

Now Available

Upgrading Existing Chilled-Water

Systems. (This program provides

designers with specific strategies for

chiller upgrades, optimization or

replacement; reusing components of a

chilled water system and help you

identify areas where control upgrades

would be beneficial.

ASHRAE 62.1 and 90.1 and VAV

Systems. (GBCI LEED-specific)

This program discusses the potentially

conflicting requirements and design

choices.

ASHRAE 62.1: Ventilation Rate

Procedure. This program covers the

Ventilation Rate Procedure for

calculating zone and system ventilation

airflow, which still exists in the standard

today. As a prerequisite to obtain LEED

certification, this program will help

viewers understand the requirements of

the Standard.

Visit www.trane.com/

ContinuingEducation to view or to see

a complete list of courses.